Lead storage battery

A lead-acid battery and electrode plate group technology, applied in lead-acid battery, lead-acid battery construction, battery pack components, etc., can solve problems such as poor corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] Hereinafter, examples of the present invention are given to further describe the configuration and effects of the present invention. In addition, this invention is not limited to these Examples.

[0056] (1) Production of lead-acid batteries

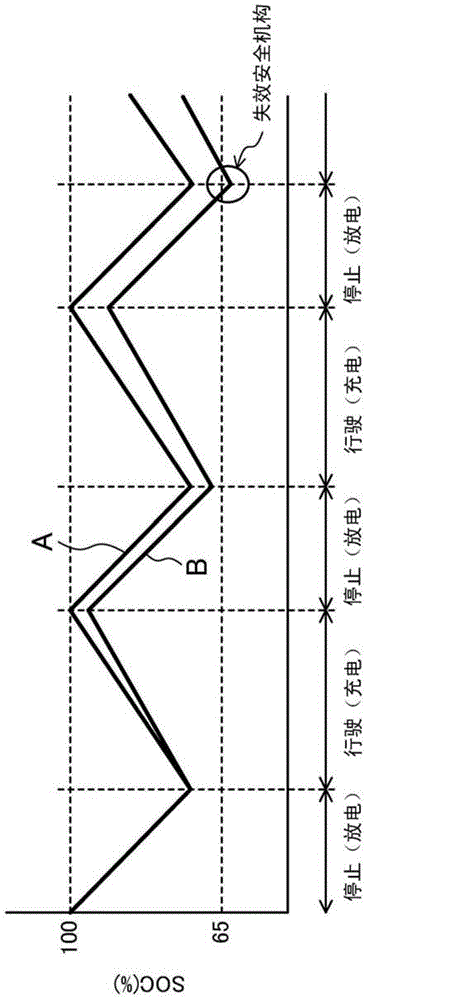

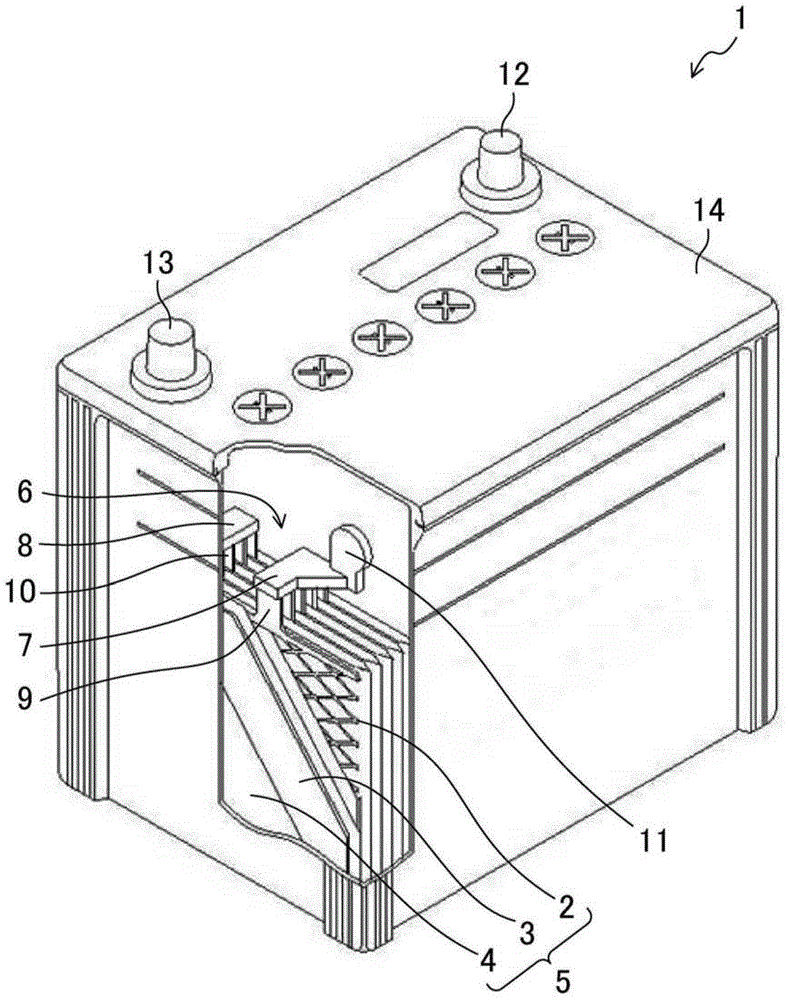

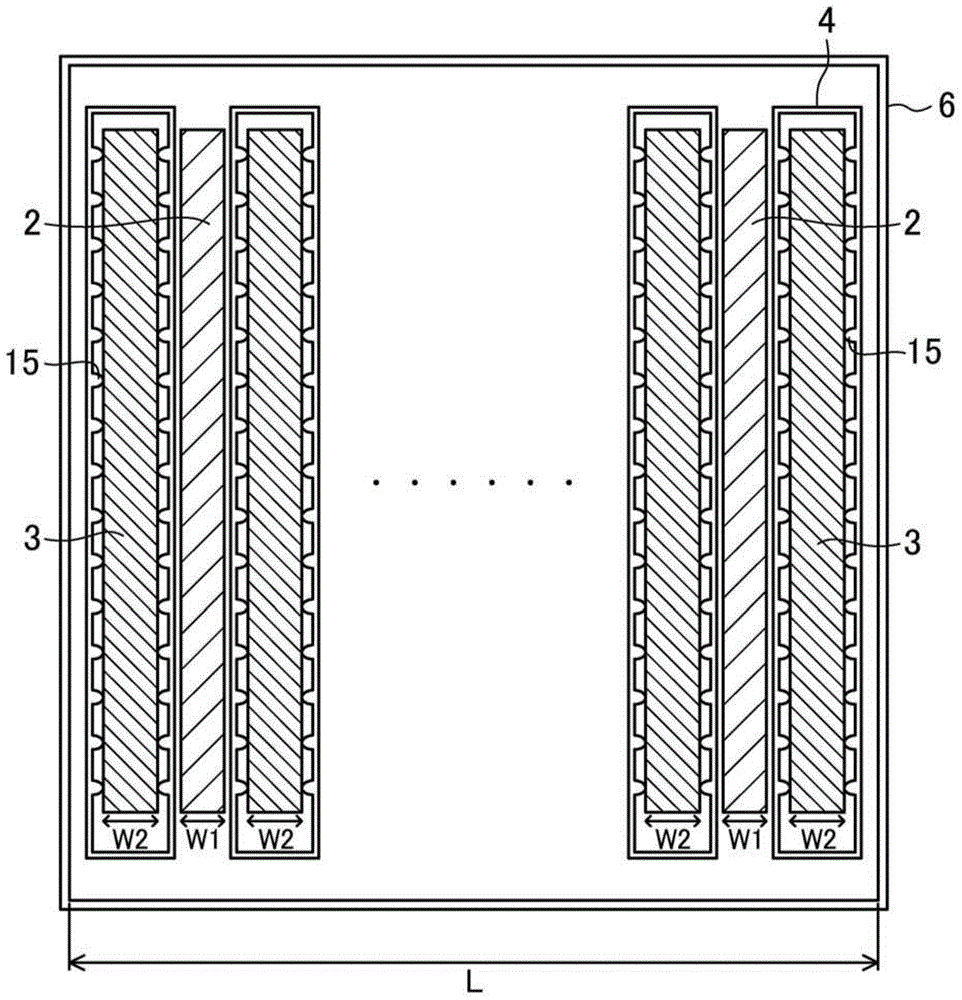

[0057] The lead storage battery 1 produced in this Example is a liquid lead storage battery of the size of D23L type prescribed|regulated by JISD5301. Seven positive electrode plates 2 and eight negative electrode plates 3 were accommodated in each unit cell 6 , and the negative electrode plates 3 were accommodated in a bag-shaped polyethylene separator 4 . A plurality of ribs 15 forming a certain gap with the negative electrode plate 3 are provided on the inner surface of the bag of the separator 4 .

[0058] Table 1 shows the configurations and battery characteristics of Batteries 1 to 16 of Examples and Batteries A and B of Comparative Examples.

[0059]

[0060] The configuration common to each battery other than the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com