A clamping and pressing device for terminal buds obliquely inserted into grafted rootstocks

A technology of pressing seedlings and slanting insertion, which is applied in the fields of application, horticulture, and botanical equipment and methods, can solve the problems of low work efficiency, long operation time, economic losses, etc., to improve work efficiency, improve work efficiency, and reduce operation. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

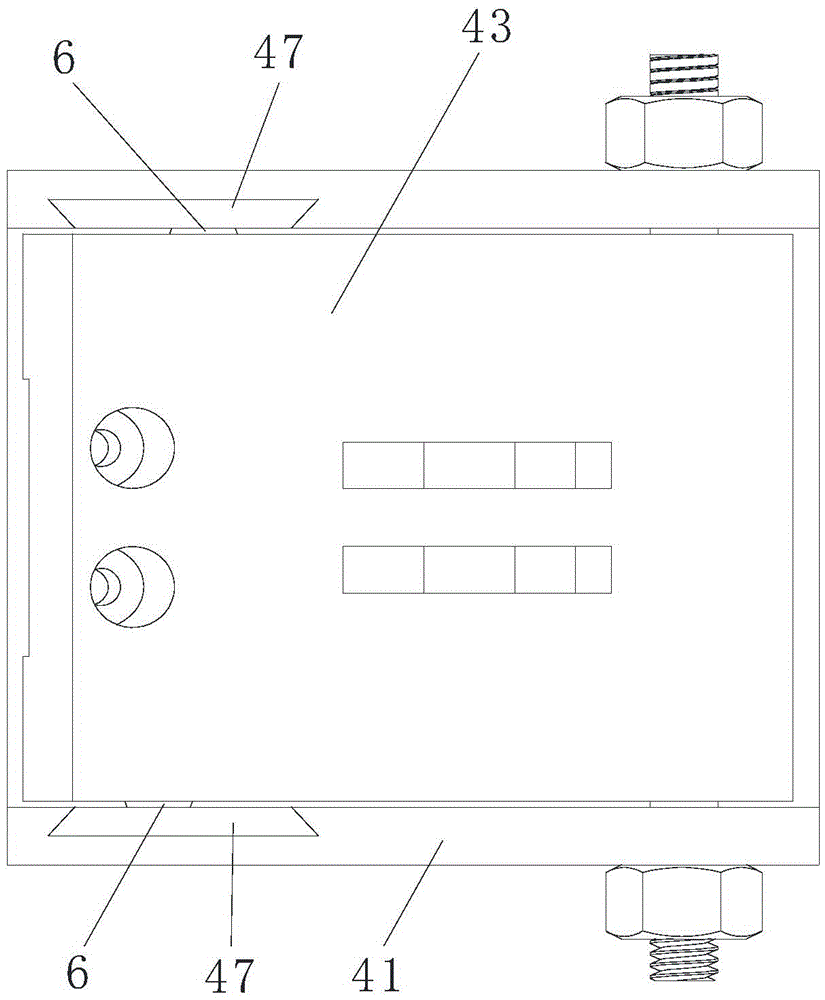

[0035] This clamping and pressing device used for terminal bud obliquely inserting grafting rootstock is the same as embodiment 1 except the following technical features: as Figure 4 As shown, the limiting block 47 is provided with two positioning holes 471, the two positioning holes 471 are located at the upper end and the lower end of the limiting block 47 respectively, and the two positioning holes 471 are close to the left side of the limiting block 47 . The two positioning holes 471 are used to limit the limit position of the rotation of the connecting frame 43, so as to prevent the connecting frame 43 from rotating at an excessively large angle and affect the working efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com