Waste gas purifying system

A waste gas purification system and pool technology, applied in the direction of air quality improvement, chemical instruments and methods, and separation of dispersed particles, can solve the problems of many manpower, material and financial resources, no chemical components in the farm, and affect people's normal life. Good effect, simple structure and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

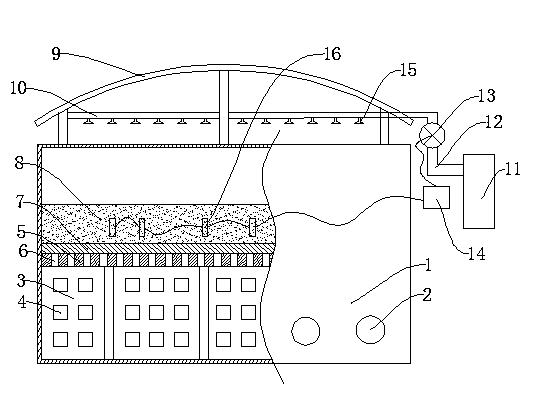

[0017] Such as figure 1 As shown, the exhaust gas purification system described in this embodiment includes a pool body 1, a support frame 3 is provided at the lower end of the pool body 1, an exhaust gas inlet 2 is provided on the side of the lower end of the pool body 1, and on the support frame 3 Laying a support plate 5 with a through hole 6, laying a deodorizing layer 8 on the support plate 5; the deodorizing layer 8 includes a strain carrier and a deodorizing bacterium, and the deodorizing bacterium is immersed in the strain carrier, The deodorant bacteria and the strain carrier are integral structures; the strain carrier is a mixture of sawdust and wood shavings, and the deodorant bacteria are attached to the strain carrier. A layer of anti-leakage mesh layer 7 is arranged between the deodorizing layer 8 and the support plate 5. The support frame 3 is composed of vertical plates arranged interlaced with each other, and a plurality of ventilation holes 4 are arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com