Excess temperature detection method and fluid control equipment in tubing soldering

A technology for controlling equipment and fluids, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of labor and time required for temperature detection, failure to detect heat transfer, heat transfer to the inside of the main body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

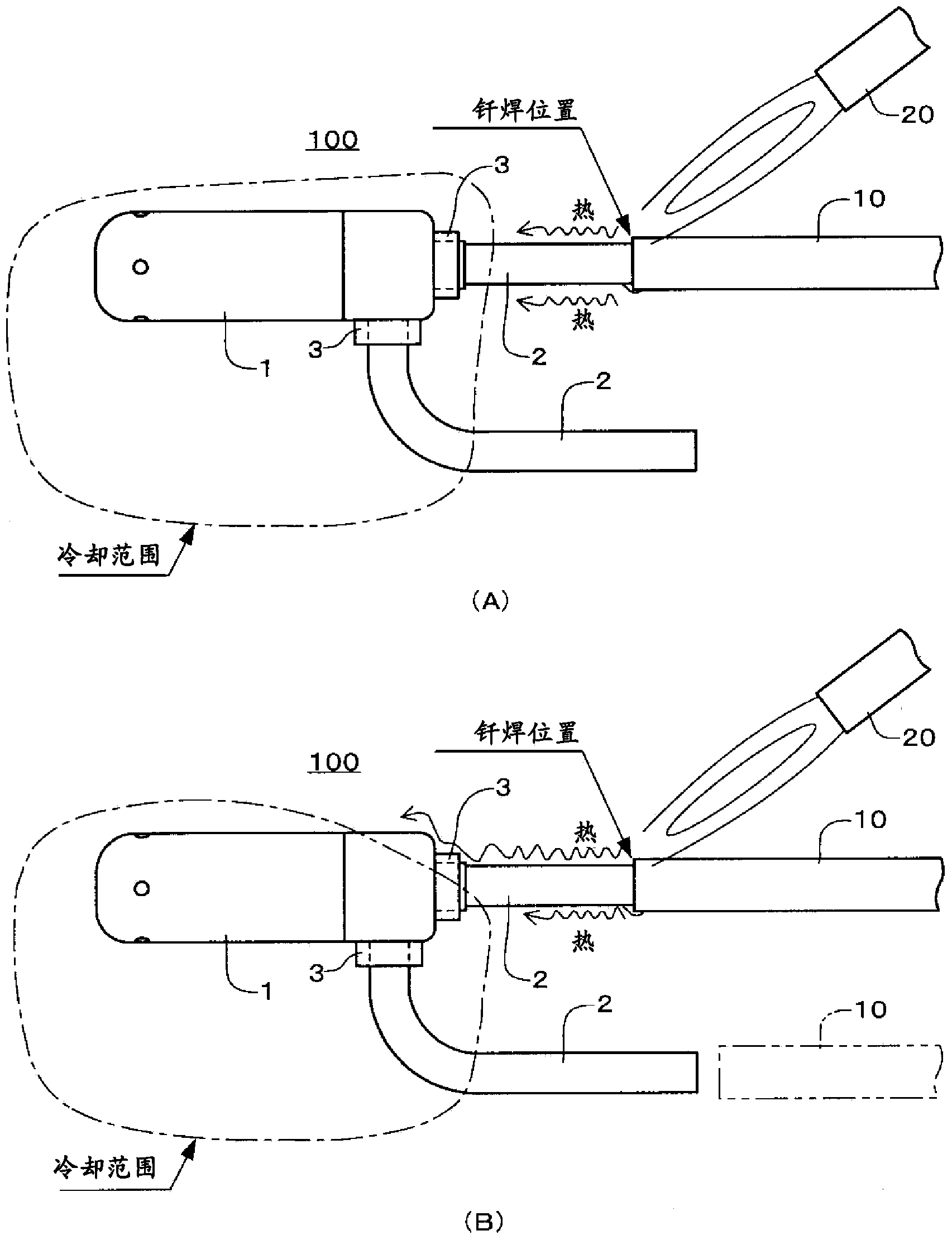

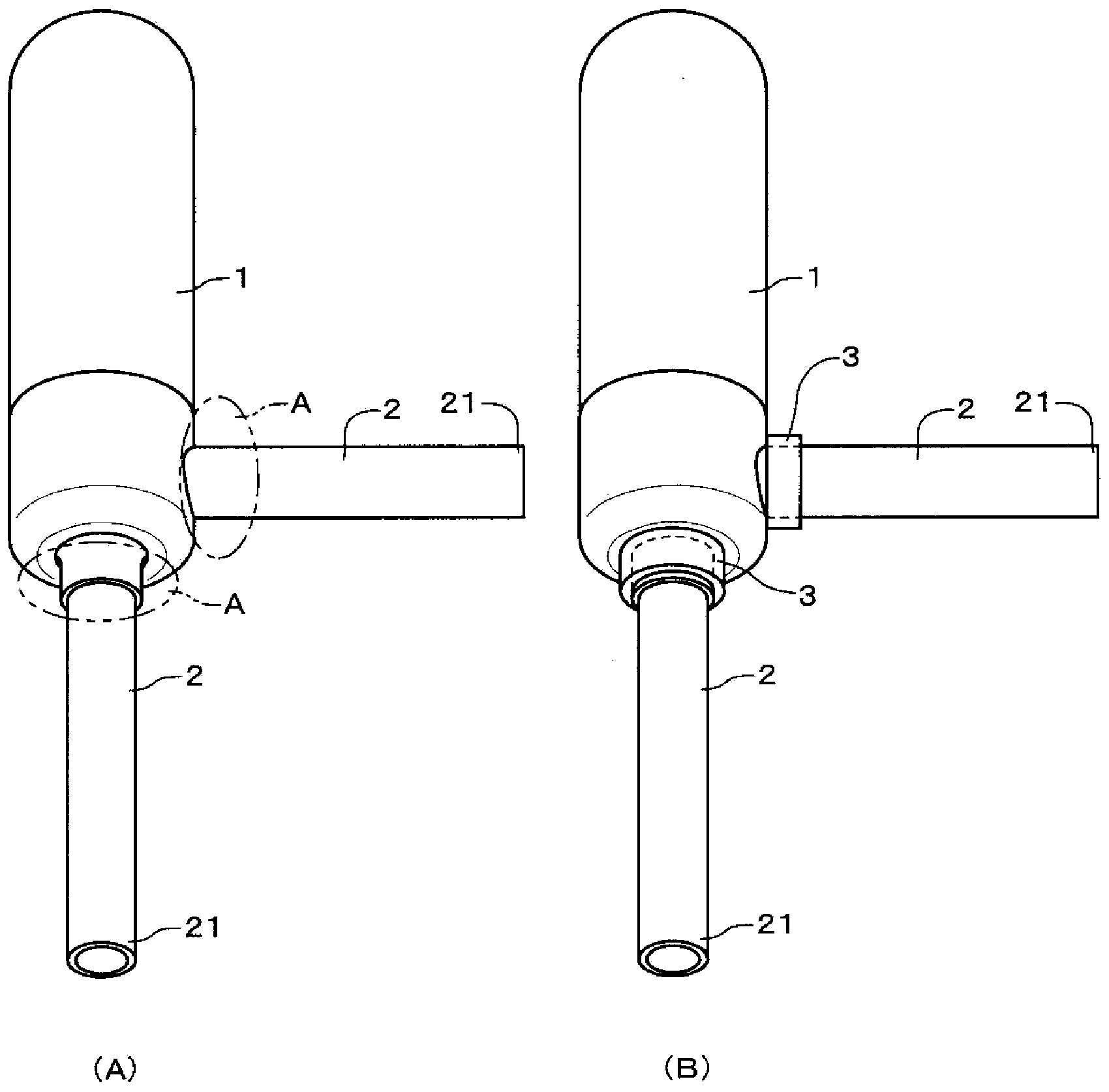

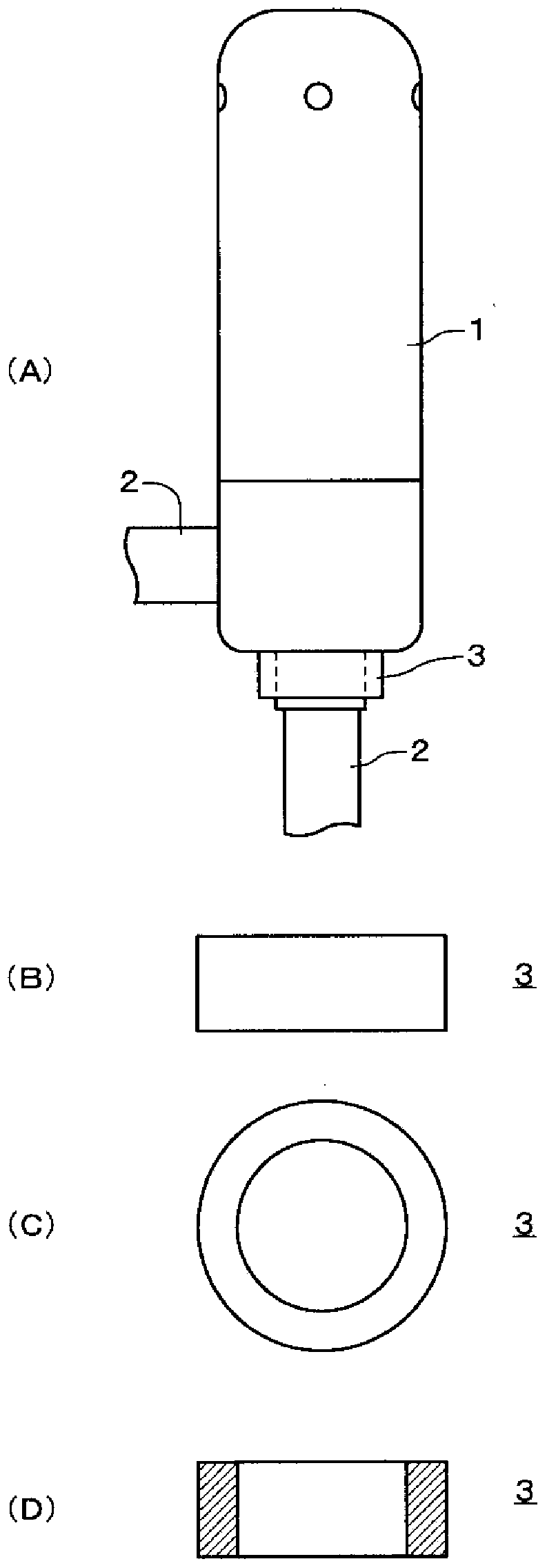

[0026] Hereinafter, embodiments of the present invention will be described with reference to the drawings. The embodiment is an example in which the fluid control device is an electric valve and the electric valve is brazed to the piping of the refrigeration cycle system (fluid circulation system). figure 1 It shows a state where the electric valve of the embodiment of the present invention has been well brazed ( figure 1 (A)), and the state where the brazing operation is not performed well ( figure 1 (B)). figure 2 Is a perspective view of the electric valve of the embodiment, figure 2 (A) is the state before the indicator 3 is installed, figure 2 (B) shows the state after the indicator 3 is installed. image 3 Is a diagram showing the detailed structure of the main part of the indicator 3 of the embodiment, image 3 (A) is a side view of the installation state of indicator 3, image 3 (B) is a side view of indicator 3, image 3 (C) is the bottom view of indicator 3. image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com