Steel pipe cutting positioning device

A technology for positioning devices and steel pipes, which is applied to tubular objects, gas flame welding equipment, applications, etc. It can solve the problems of affecting efficiency, high price, and bulkiness, and achieve the effects of easy portability, regular cuts, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

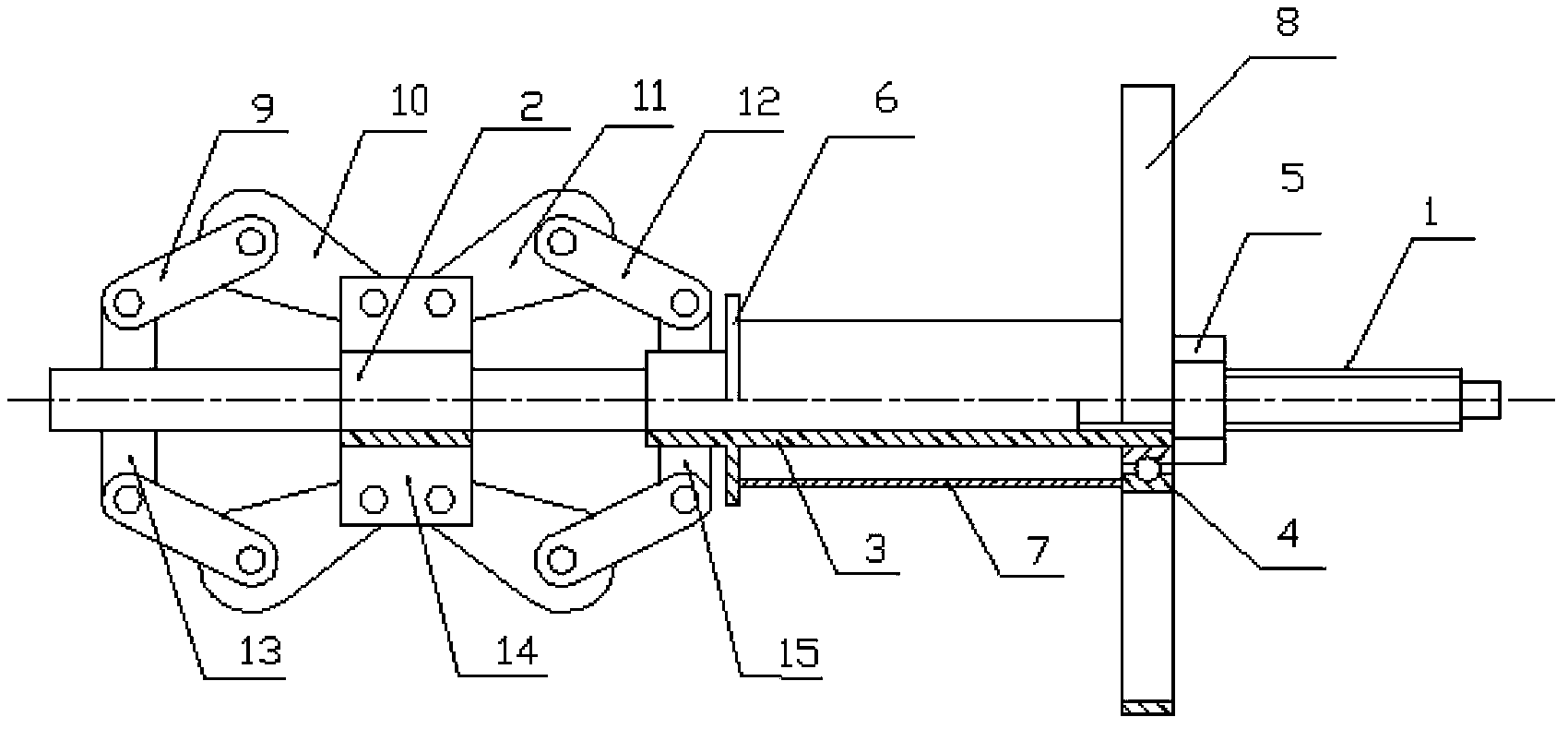

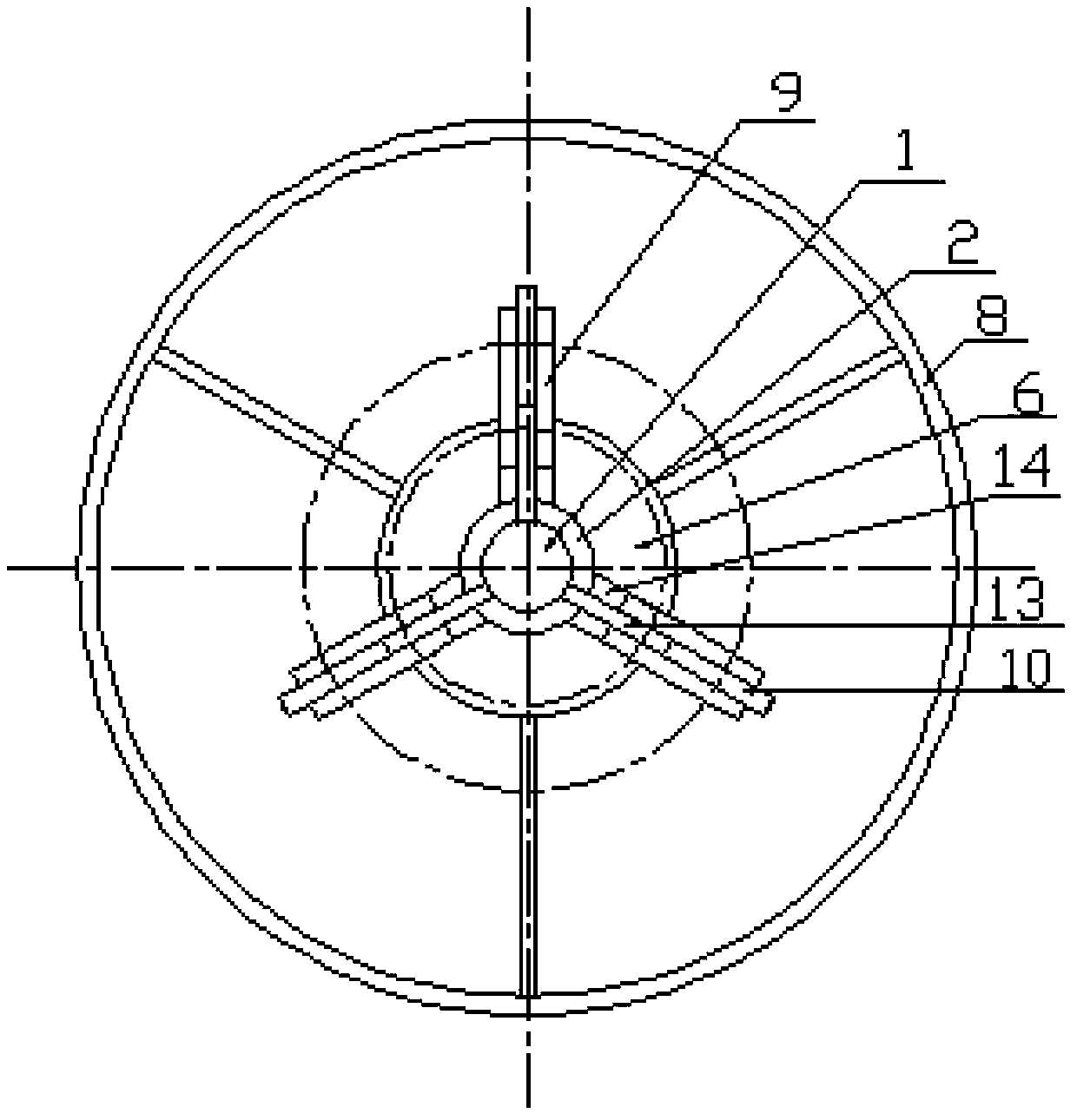

[0024] Such as figure 1 As shown, the steel pipe cutting positioning device of the present invention consists of a tensioning pull rod 1, a traveling sleeve 2, a positioning sleeve 3, a bearing 4, a lock nut 5, a baffle plate 6, a protective tube 7, a cutting torch installation accessory 8, and a first positioning Support sheet 9, the second positioning support sheet 10, the third positioning support sheet 11, the fourth positioning support sheet 12, the first fixed sheet 13, the second fixed sheet 14, and the third fixed sheet 15. One end of the tensioning rod 1 is a screw thread, the end is a square head, and the other end is welded with three first fixed pieces 13 distributed at 120°. There is a screw hole on the first fixed piece 13; On the tie rod 1, adjacent to the first fixed piece 13 on the tensioning tie rod 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com