Spinning machine

A textile machine and textile board technology, which is applied in textiles, textiles, papermaking, and auxiliary equipment for weaving. It can solve the problems of low dust absorption efficiency, improve air quality, increase production costs, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

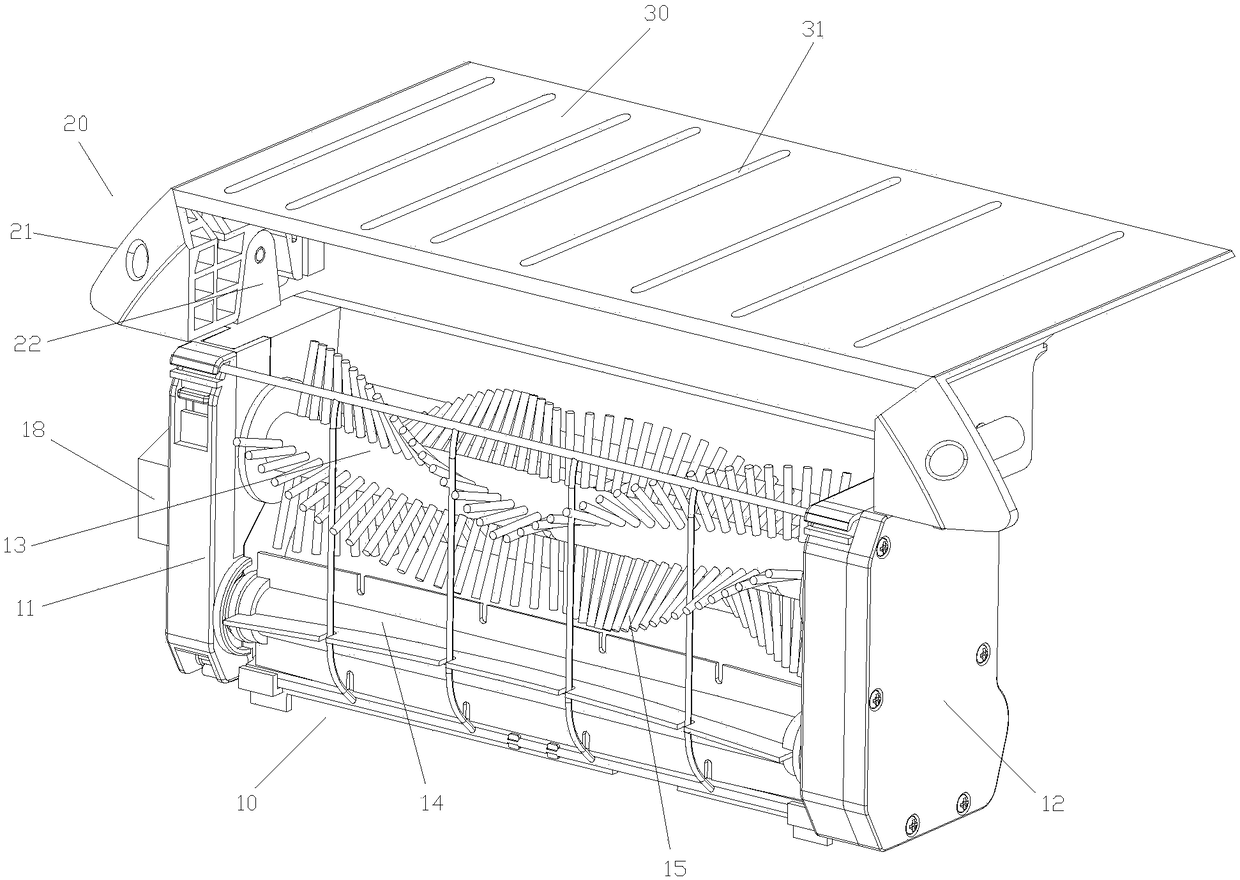

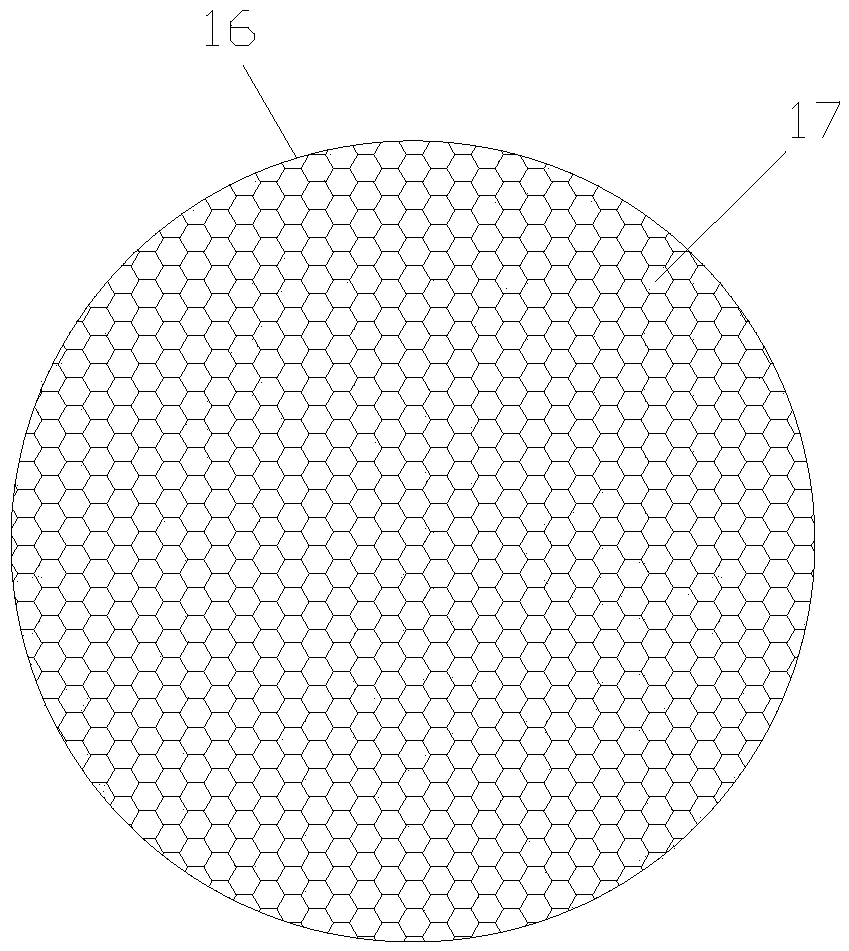

[0013] Such as figure 1 with figure 2 As shown, as a preferred embodiment, the present invention proposes a textile machine, which includes a dust suction device 10 and a textile board 30. The dust suction device 10 includes a left fixing plate 11 and a right fixing plate 12, the left fixing An absorption main pipe 13 and a collecting pipe 14 are fixedly connected between the plate 11 and the right fixing plate 12. The right fixing plate 12 has a cavity, and the absorption main pipe 13 and the collecting pipe 14 are fixedly connected to the right fixing plate 12 The cavities are in communication, the absorption main pipe 13 is provided with multiple rows of absorption capillaries 15 along the axial direction, and the absorption capillaries 15 are provided with a number of through holes (for aesthetics, not shown in the figure), the collection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com