Forming protective jacket

A technology of protective sleeve and forming sleeve, which is applied in the direction of threaded fasteners, connecting components, nuts, etc., can solve the problems of uneven application of sealant and difficulty in forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

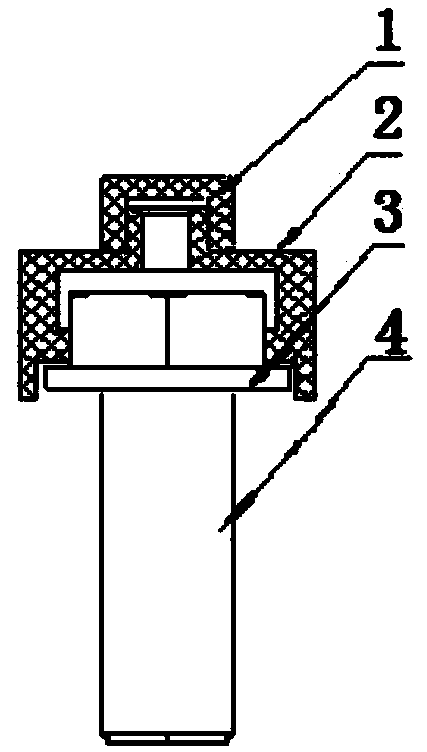

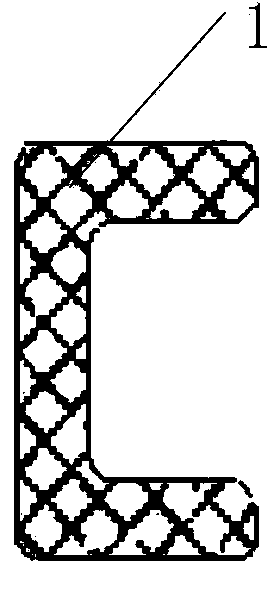

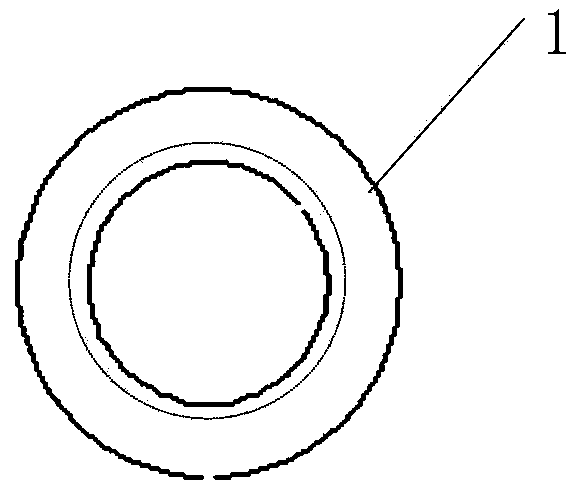

[0016] During the implementation of the present invention, the design purpose of the present invention is firstly introduced.

[0017] The molding protective sleeve designed by the present invention is mainly to solve the problems of two aspects:

[0018] (1) Solve the problems that the glue coating process is not easy to implement due to the fluidity of the sealant in the glue coating process, uneven glue coating on bolt heads or nuts, and inconsistent appearance. The molded protective sleeve designed by the present invention mainly plays the role of a mould, ensuring consistent usage of the sealant. The glue coating process can be simplified through the forming protective sleeve, ensuring that the glue is coated on the surface of the bolt head or the nut without flowing randomly.

[0019] (2) The molded protective sleeve has a certain protective effect on the sealant, solving the problem of premature aging of the sealant due to environmental impacts such as sun exposure, wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com