Constant-speed universal joint driving shaft assembly

A technology of drive shafts and universal joints, applied in the direction of couplings, elastic couplings, mechanical equipment, etc. Affect the service life of the drive shaft assembly and other issues to achieve the effect of enhancing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

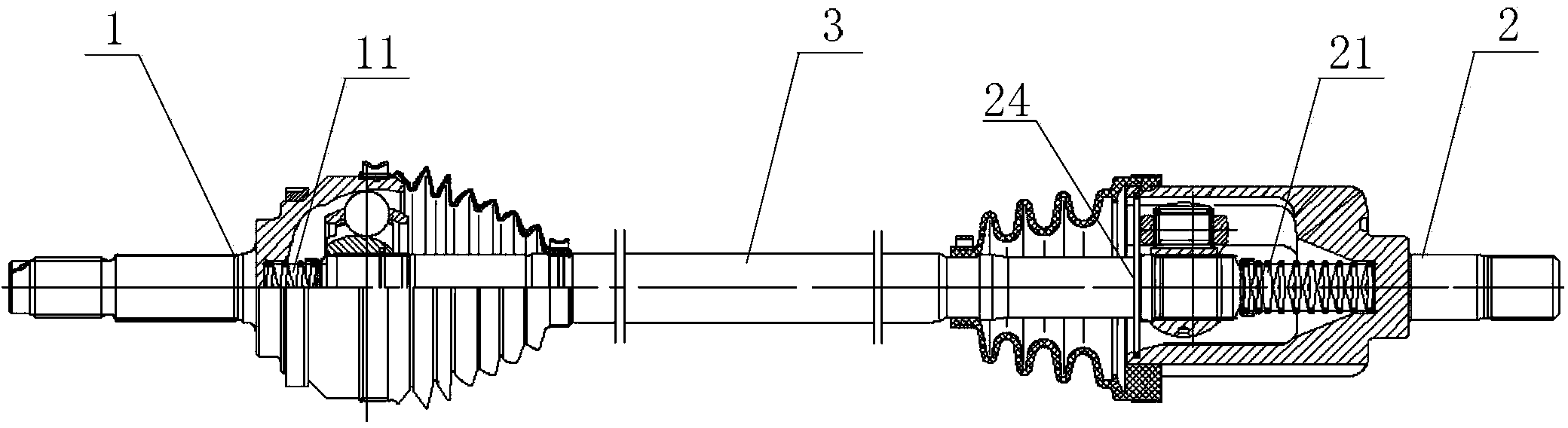

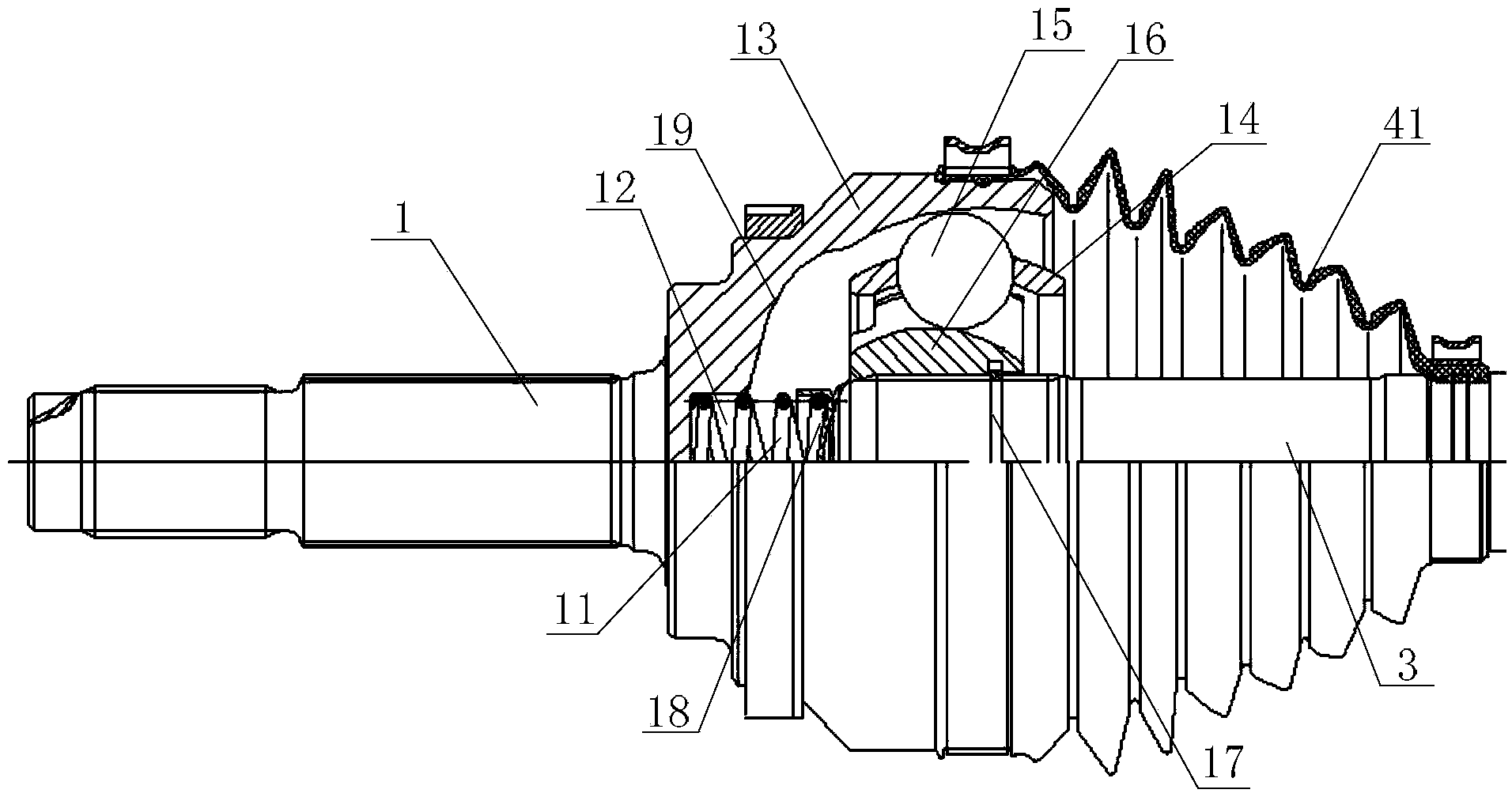

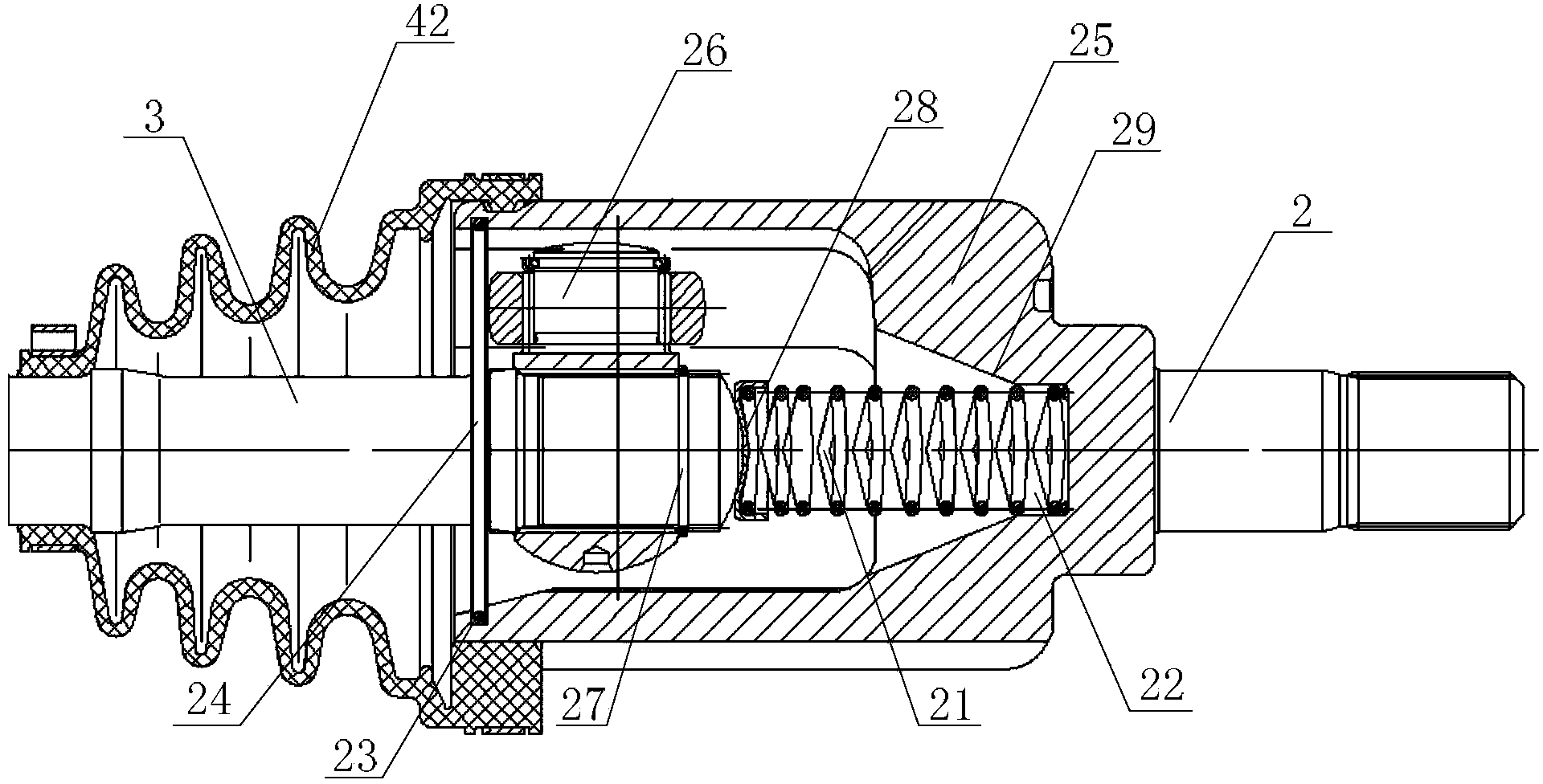

[0024] An embodiment of the present invention provides a constant velocity universal joint drive shaft assembly, see Figure 1-3 , the drive shaft assembly includes a fixed cage universal joint 1, a movable cage universal joint 2, and an intermediate shaft 3 connected to the fixed cage universal joint 1 and the movable cage universal joint 2 at both ends , the fixed ball cage universal joint 1 is provided with a first pressure spring 11, the first pressure spring 11 is arranged along the axial direction of the intermediate shaft 3 and abutted between the fixed ball cage universal joint 1 and one end of the intermediate shaft 3 Between; the mobile cage universal joint 2 is provided with a second pressure spring 21, the second pressure spring 21 is arranged along the axial direction of the intermediate shaft 3 and abutted against one end of the movable cage universal joint 2 and the intermediate shaft 3 between.

[0025] Specifically, in this embodiment, the fixed ball cage uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com