Dry plate clutch with steel plates avoiding loose engagement

A clutch and double clutch technology, applied in the field of disc clutches of trucks or trucks, can solve problems such as dissatisfaction with drag torque, achieve compact structure, simplify installation process, and reduce the effects of separate components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

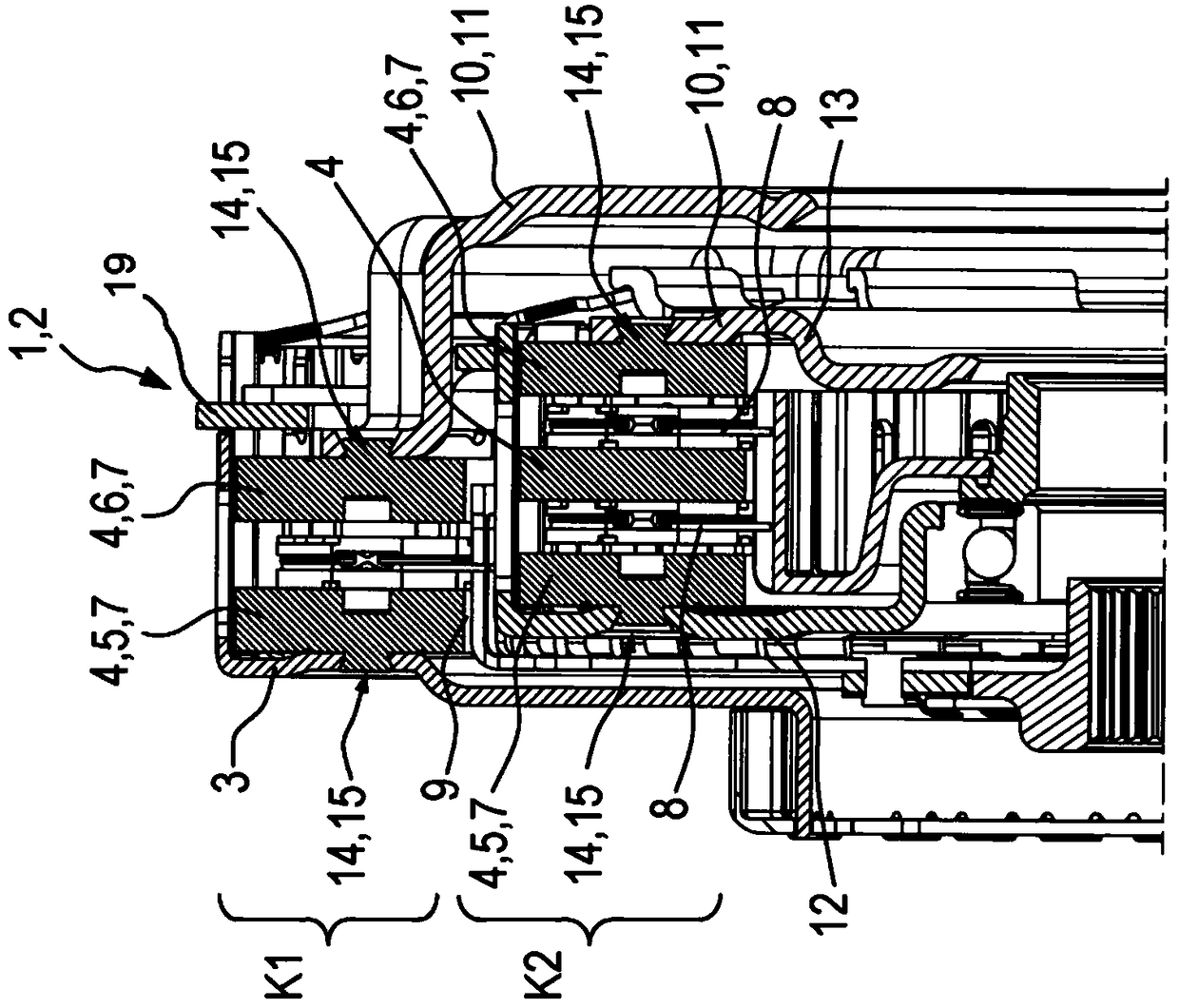

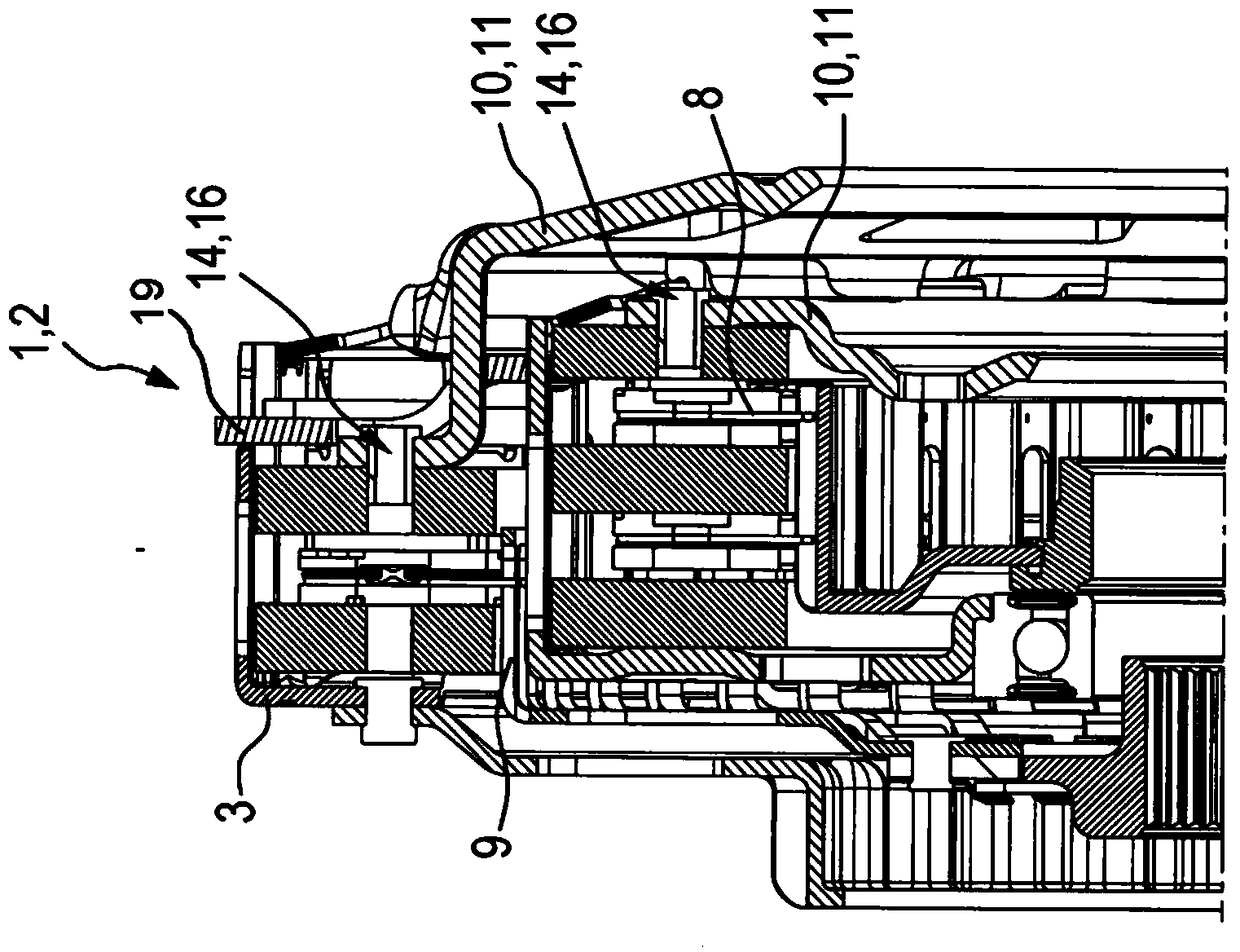

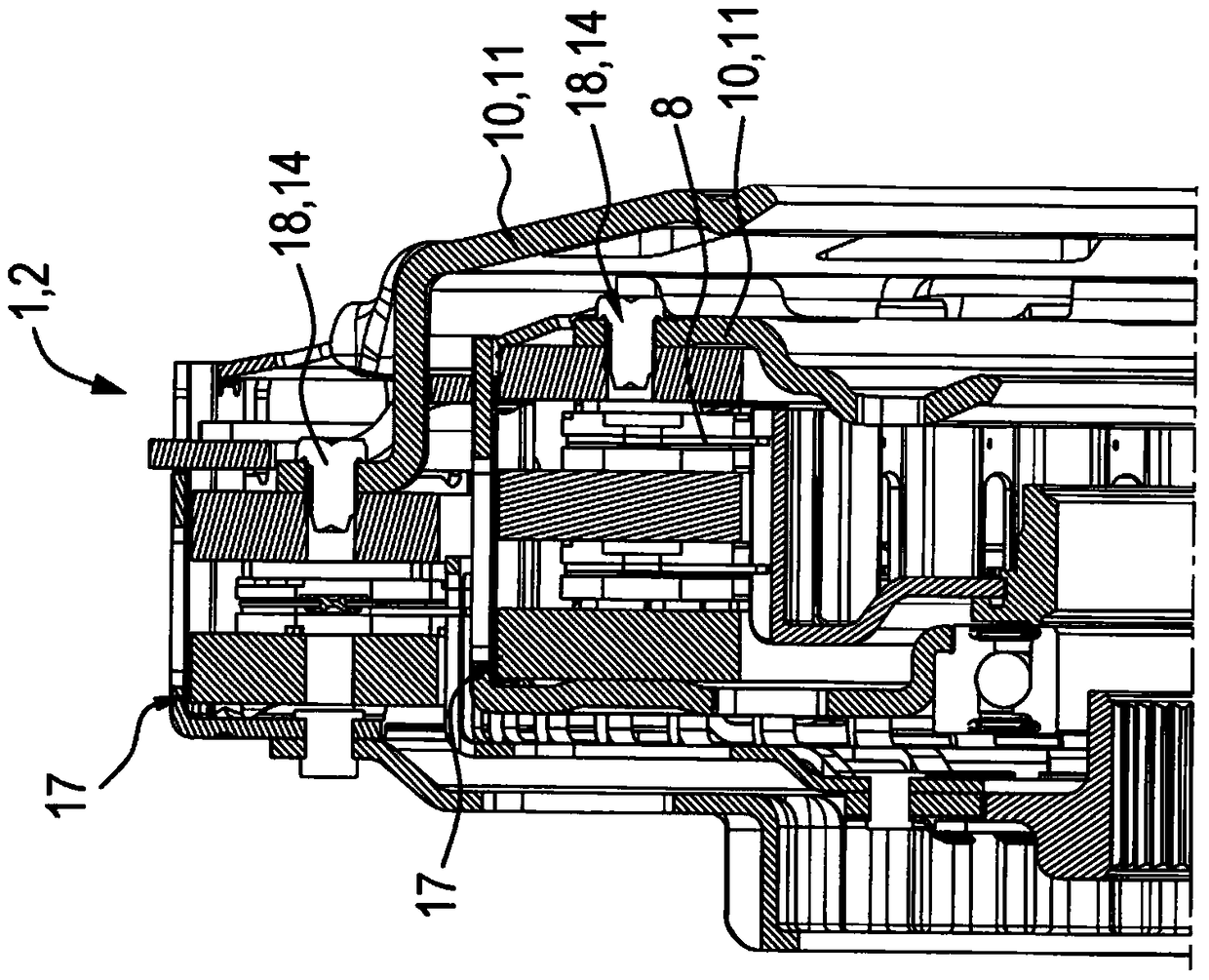

[0041] The drawings are of a schematic nature and serve only for the understanding of the invention. Identical elements are provided with the same reference numerals.

[0042] exist figure 1 A first embodiment of the multi-disk clutch 1 according to the invention is shown in . The multi-disk clutch 1 is intended for use in a motor vehicle, such as a passenger car or a truck, and is used in the drive train in particular when an internal combustion engine is connected to the drive train.

[0043] The multi-disk clutch 1 is designed as a double clutch 2 . The multi-disk clutch 1 has a first (torque) input-side multi-disk carrier 3 . At least two flaps 4 are joined to the first input side flap carrier 3 in a rotationally fixed manner. The sheet 4 of the sheet carrier 3 axially next to the input side is referred to as the first sheet 5 , whereas the other sheet 4 is referred to as the last sheet 6 . The first piece 5 and the last piece 6 are end pieces 7 . The first sheet 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com