Novel sealing ring for submersible motor

A technology of submersible motors and sealing rings, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., and can solve problems such as gap bite, seal failure, and submersible motor seal failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The structure and implementation mode of the present invention will be further explained below in conjunction with the accompanying drawings.

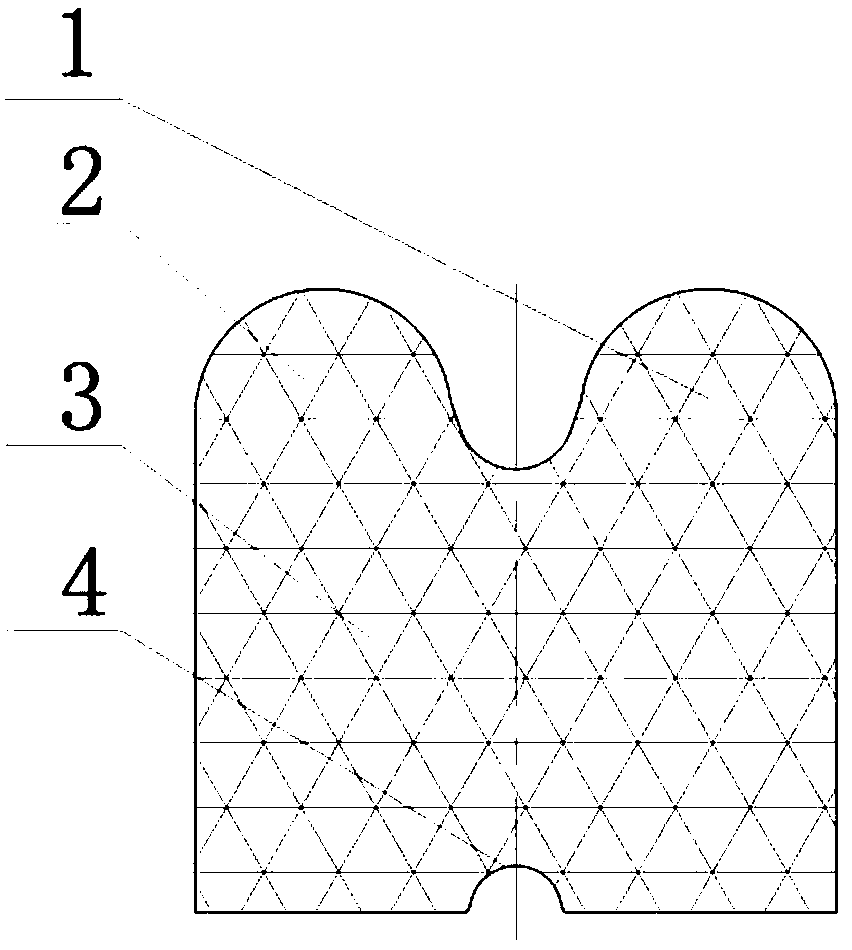

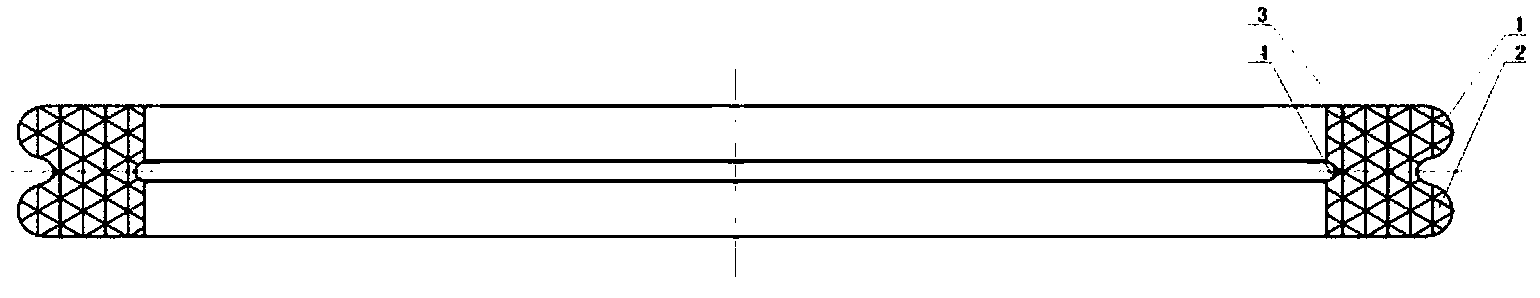

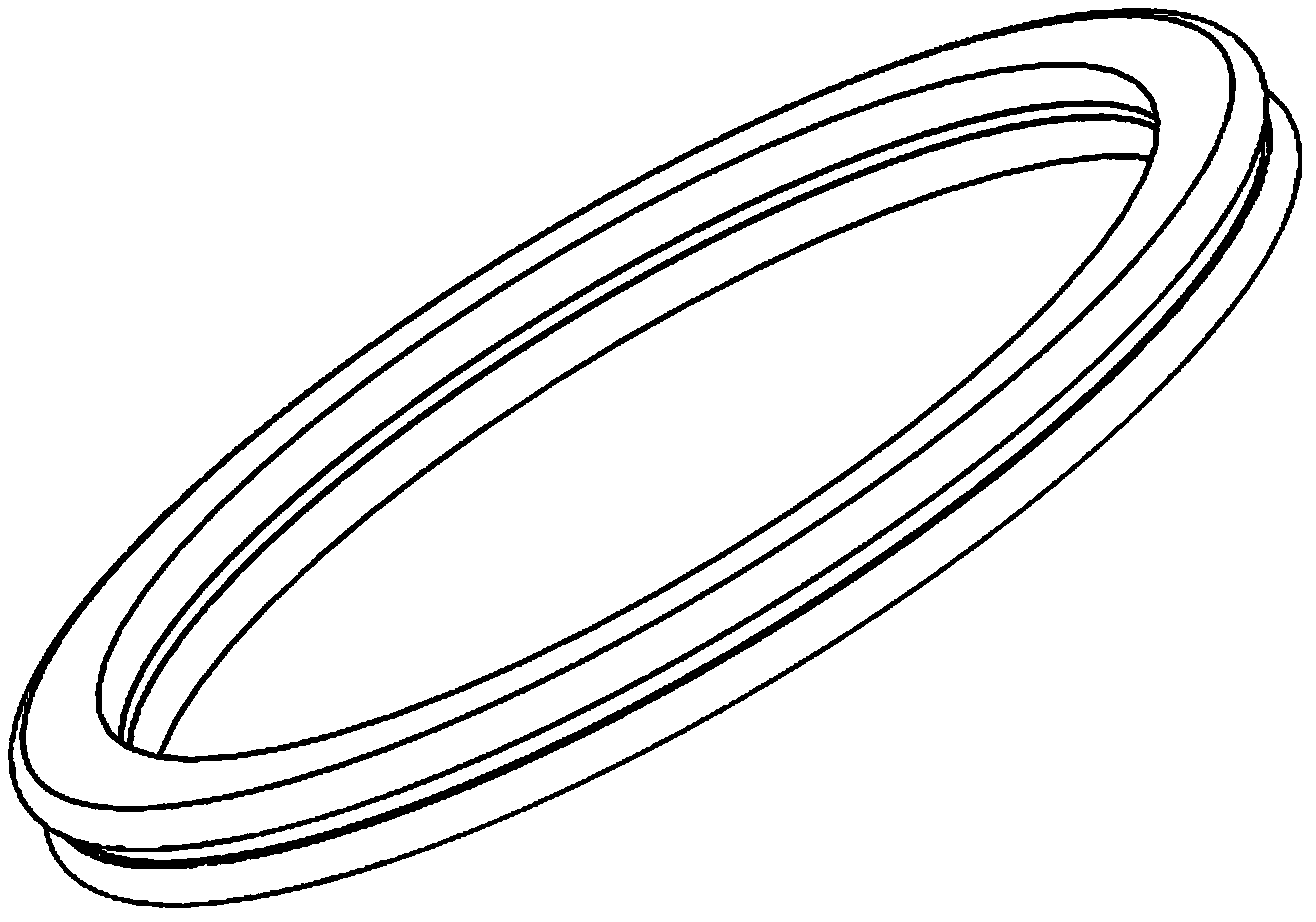

[0010] Such as figure 1 As shown, a new sealing ring for submersible motors includes: left sealing lip 1, right sealing lip 2, ring body 3, and semicircular notch 4. The present invention is made of fluorine rubber, the left sealing lip 1 and the right sealing lip 2 are located on the top of the ring body 3, and are symmetrically distributed, and the semicircular notch 4 is located in the middle of the bottom of the ring body 3. The left sealing lip 1 and the right sealing lip 2 can both produce a sealing effect under the action of pressure, and play the role of double sealing; the left and right sides of the ring body 3 are vertical cut surface structures, which will not be squeezed into the sealing gap and cause bites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com