Flyback switching power circuit

A technology of switching power supply circuit and flyback circuit, which is applied in the direction of high-efficiency power electronic conversion, electrical components, output power conversion devices, etc., can solve the problems of small size, etc., and achieve good protection performance, good EMI performance, and good absorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

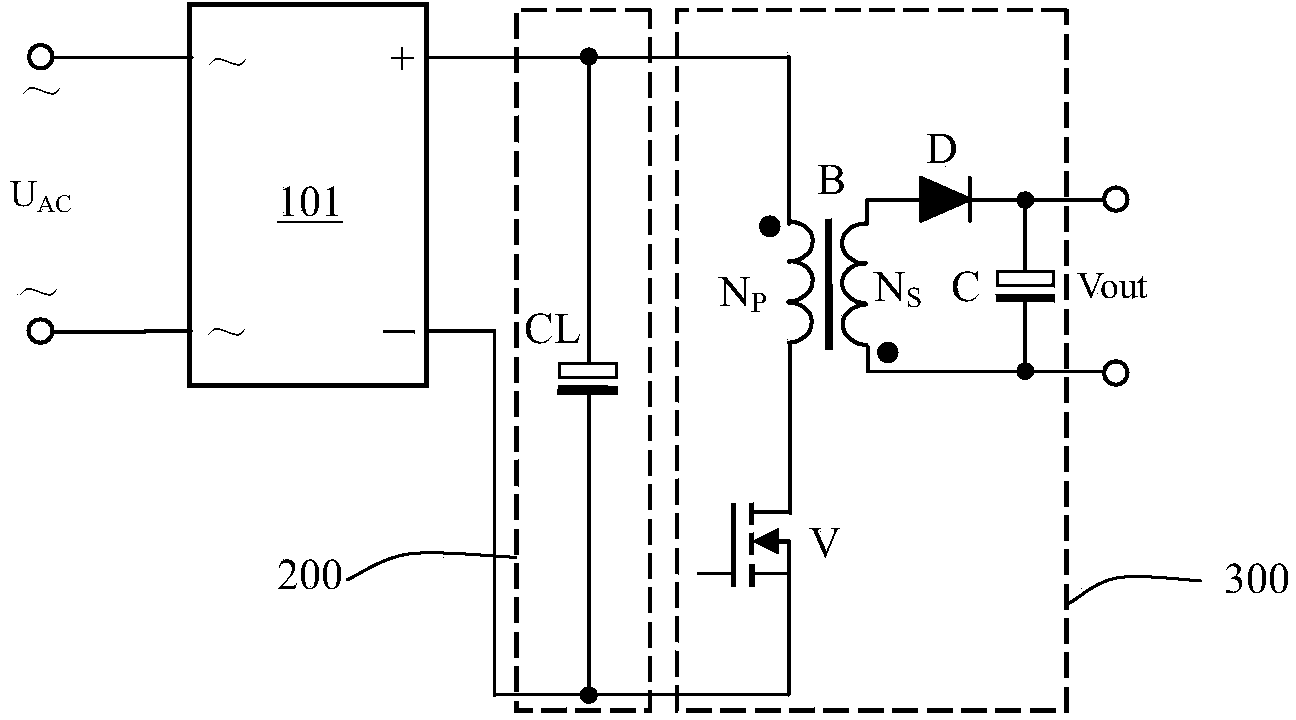

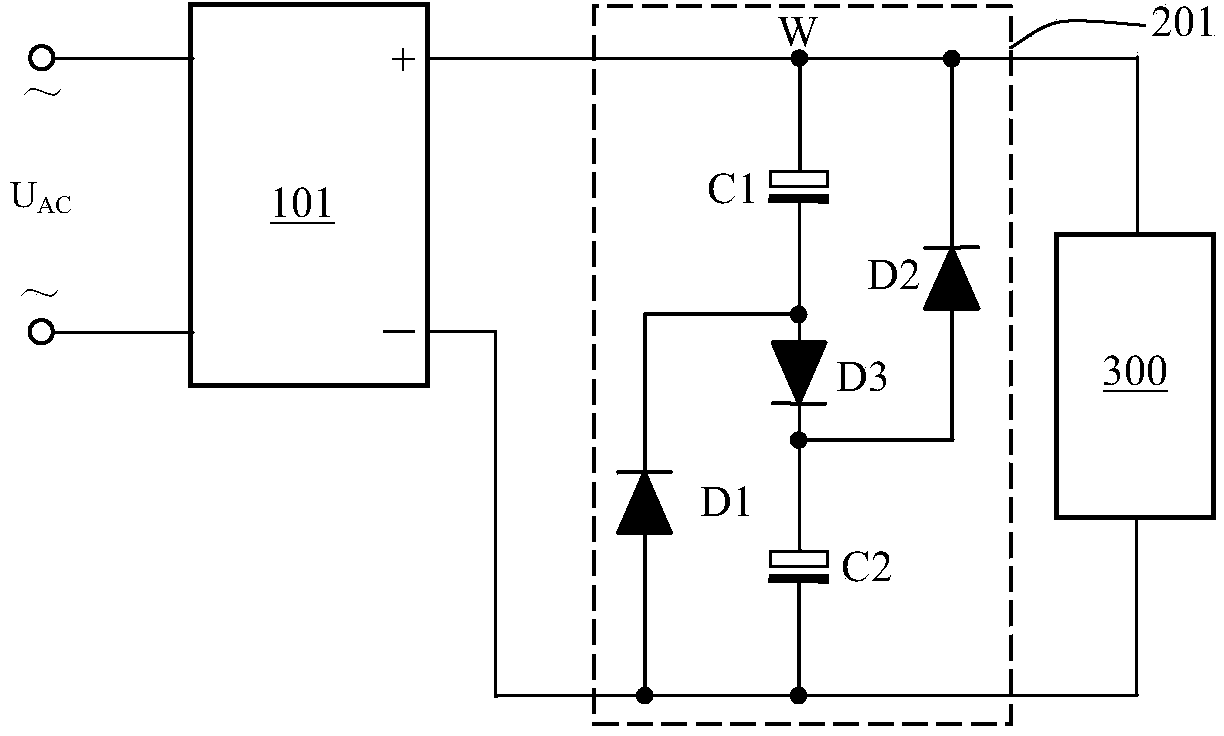

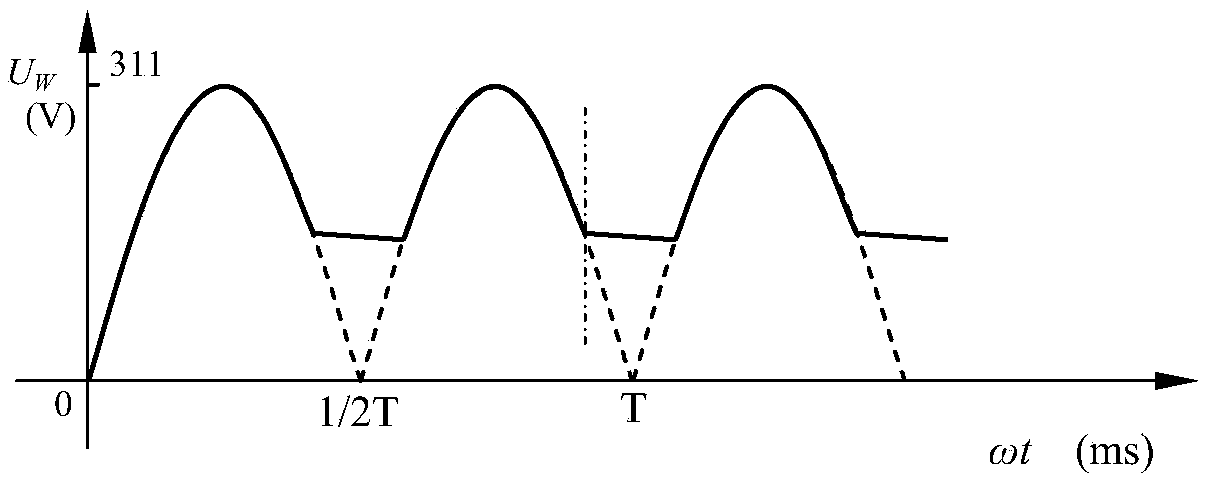

[0061] Figure 5 Shows the schematic diagram of the flyback switching power supply circuit of the first embodiment, a flyback switching power supply circuit for direct connection to the AC input U AC , including a valley filling circuit 203, a rectifier circuit 202 with a protection function located at the front stage of the valley filling circuit, and a flyback circuit 300, the flyback circuit 300 is the same as that in the prior art, see figure 1 The circuit part of the 300:

[0062] AC input U AC It has a first terminal O1 and a second terminal O2; it is connected with a rectifier circuit 202 with a protection function, and the rectifier circuit 202 with a protection function includes two interchangeable input terminals, which are Figure 5 The two ends of the first piezoresistor RV1, and the positive output terminal (the V of the rectifier bridge 101 O+ and the terminal connected to the second varistor RV2) and the negative output terminal (the V of the rectifier bridge...

no. 2 example

[0091] Figure 7 It shows the schematic diagram of the flyback switching power supply circuit of the second embodiment, a flyback switching power supply circuit for direct connection to the AC input U AC , including a valley filling circuit 203, and a rectifier circuit 202 with protection function located at the front stage of the valley filling circuit, the AC input U AC It has a first terminal O1 and a second terminal O2, connected to a rectifier circuit 202 with a protection function, and the rectifier circuit 202 with a protection function includes two interchangeable input terminals, which are Figure 7 The two ends of the first piezoresistor RV1, and the positive output terminal (the V of the rectifier bridge 101 O+ and the terminal connected to the second varistor RV2) and the negative output terminal (the V of the rectifier bridge 101 O- and the terminal connected to the second piezoresistor RV2);

[0092] The circuit connection relationship of the valley filling ci...

no. 3 example

[0097] Figure 8 Shows the schematic diagram of the flyback switching power supply circuit of the third embodiment, a flyback switching power supply circuit for direct connection to the AC input U AC , including the valley filling circuit 203 ', and the rectifier circuit 202 with protection function located at the front stage of the valley filling circuit, the AC input U AC It has a first terminal O1 and a second terminal O2, connected to a rectifier circuit 202 with a protection function, and the rectifier circuit 202 with a protection function includes two interchangeable input terminals, which are Figure 8 The two ends of the first piezoresistor RV1, and the positive output terminal (the V of the rectifier bridge 101 O+ and the terminal connected to the second varistor RV2) and the negative output terminal (the V of the rectifier bridge 101 O- and the terminal connected to the second piezoresistor RV2);

[0098] The difference from the first and second embodiments is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com