Enzyme deactivating mechanism used for daisy enzyme deactivating machine

A greening machine and greening technology, applied in the direction of tea substitutes, etc., can solve the problems of low steam utilization rate and poor killing effect, and achieve the effect of ensuring the killing effect, scientific layout, and high steam utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0034] Example.

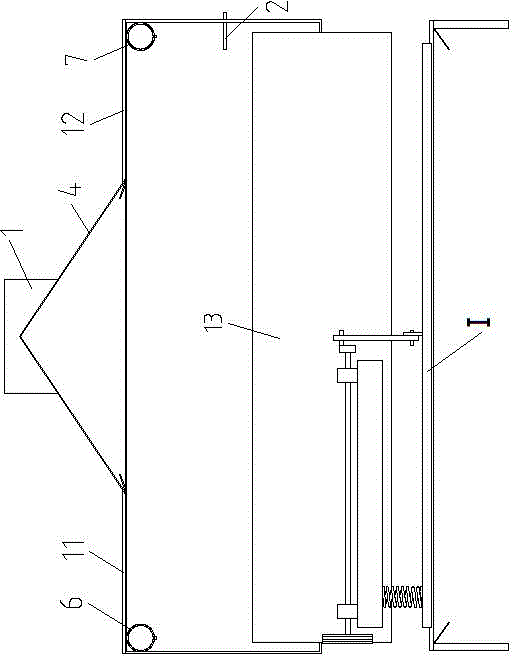

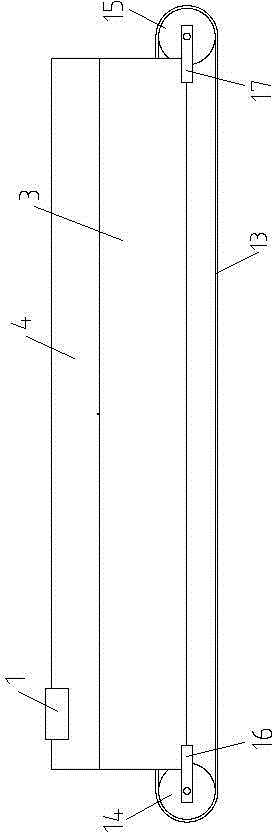

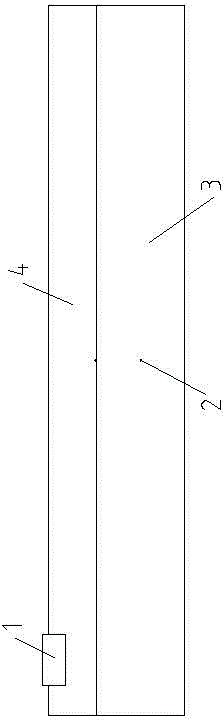

[0035] see Figure 1 to Figure 17 , the greening mechanism used in the tire chrysanthemum greening machine in this embodiment includes a frame, a fan 1, a temperature sensor 2, a steam chamber 3, a steam cover 4, an upper main steam pipe 5, a top left steam pipe 6, and a top right side. Steam pipe 7, lower main steam pipe 8, several bottom steam pipes 9, several supporting horizontal bars 10, left drain pipe 11, right drain pipe 12, fetal chrysanthemum cleaning conveyor belt 13, driving roller 14, driven roller 15, The driving roller mounting frame 16, the driven roller mounting frame 17 and the uniform unloading device I, wherein the temperature sensor 2 is installed in the steam chamber 3.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com