A nanoscale extraction system of plant components

A full-component, nano-scale technology, applied in the field of extraction, to achieve the effect of low power consumption, fast extraction speed and flexible selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below according to the accompanying drawings.

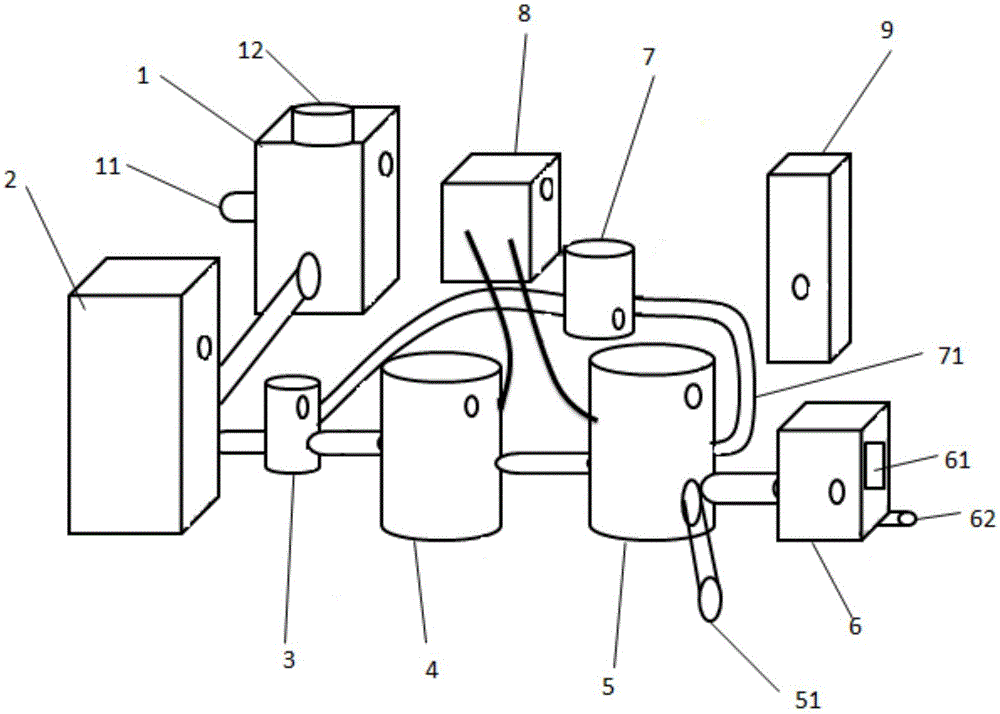

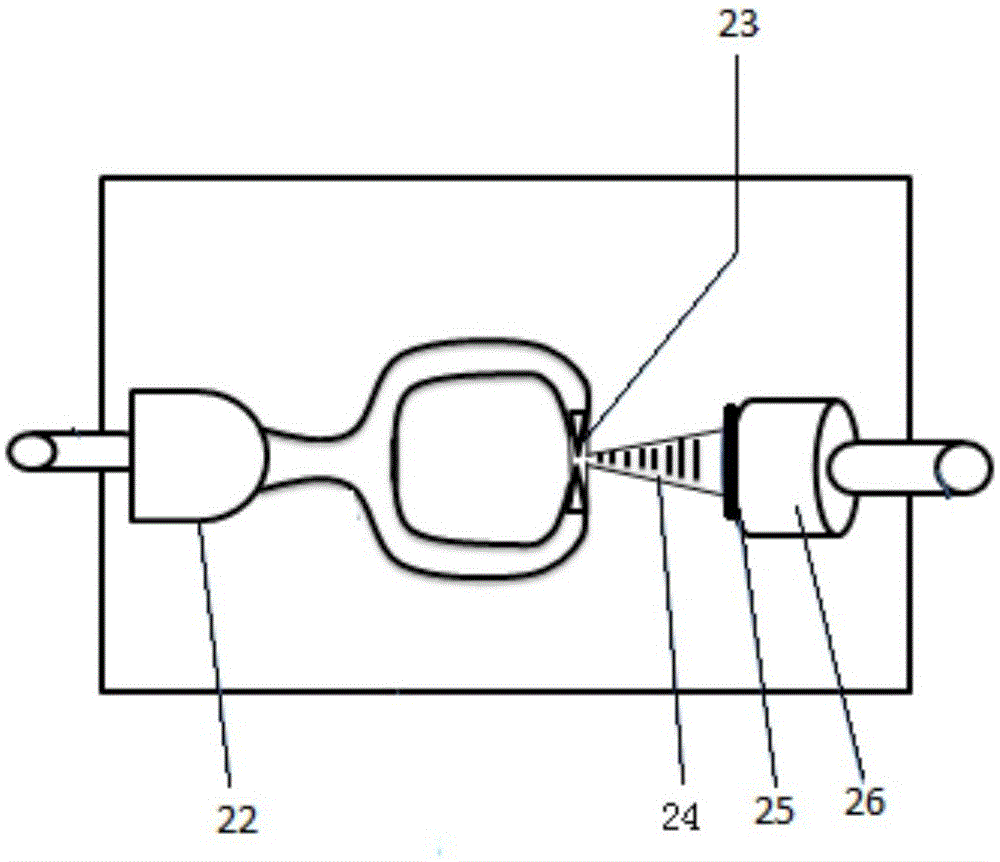

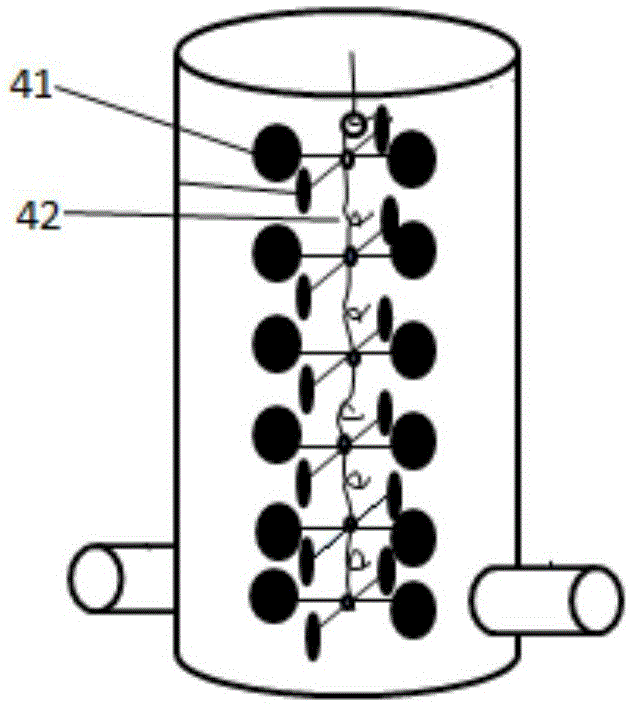

[0026] Such as Figure 1 to Figure 6 As shown, the outlet of the rubber mill 1 is connected to the inlet of the homogenizer 2 through a pipeline, the outlet of the homogenizer 2 is connected to an inlet of the high-pressure pump 3, the outlet of the high-pressure pump 3 is connected to the inlet of the ultrasonic pressure chamber 4, and the ultrasonic pressure chamber 4 The outlet of the microwave pressure chamber 5 is connected to the inlet of the microwave pressure chamber 5, and the microwave pressure chamber 5 is provided with 3 outlets, one outlet of the microwave pressure chamber 5 is connected to the inlet of the dryer 6, the other outlet of the microwave pressure chamber 5 is connected to the liquid outlet 51, and the microwave pressure chamber 5 is connected to the liquid outlet 51. The third outlet of 5 is connected to one end of the magnetic force pump 7 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com