Driving tool with anti-skid structure

A technology for driving tools and electrician pliers, applied in manufacturing tools, hand-held tools, workpiece clamping devices, etc., can solve problems such as bite marks on the surface of workpieces, and achieve the effect of reducing bite marks and improving identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0048] Example 1

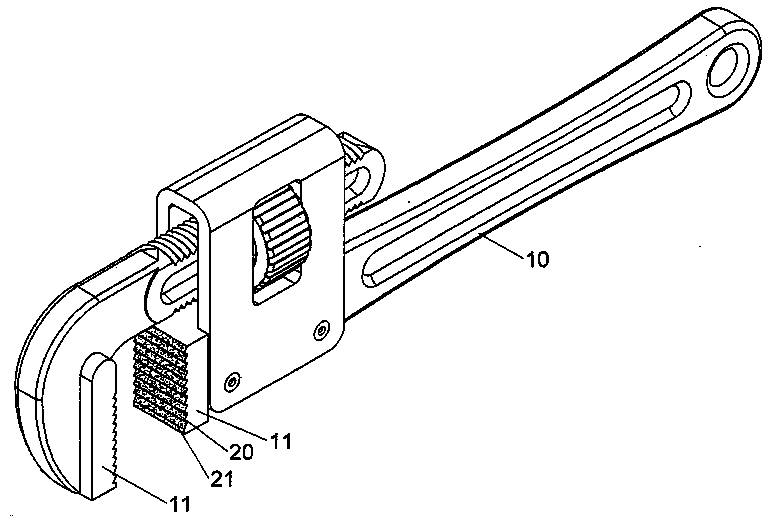

[0049] see figure 1 , the driving tool with the anti-skid structure according to the first embodiment of the present invention is a pipe wrench. The pipe wrench includes a main body 10 . The main body 10 is provided with an action end 11 , the action end 11 is the surface contacting the driven workpiece, and the action end 11 is provided with teeth arranged in a straight line.

[0050]A grinding wheel body 20 , the grinding wheel body 20 is arranged on the working end 11 of the main body 10 , the grinding wheel body 20 is the grinding wheel particles evenly distributed on the surface of the working end 11 , forming a friction surface 21 , and the friction surface 21 is used for the function of the main body 10 . When the end 11 is in contact with the workpiece, the friction force is increased, that is, the contact friction force between the two is increased, so as to prevent the workpiece or other objects from sliding away from the action end 11 .

[0051]...

Example Embodiment

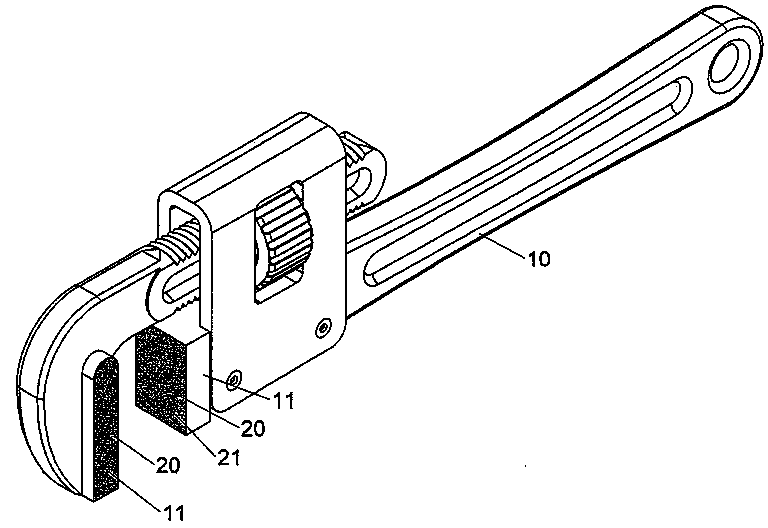

[0054] Embodiment 2

[0055] see figure 2 . In this embodiment, the action end 11 of the body 10 is flat.

Example Embodiment

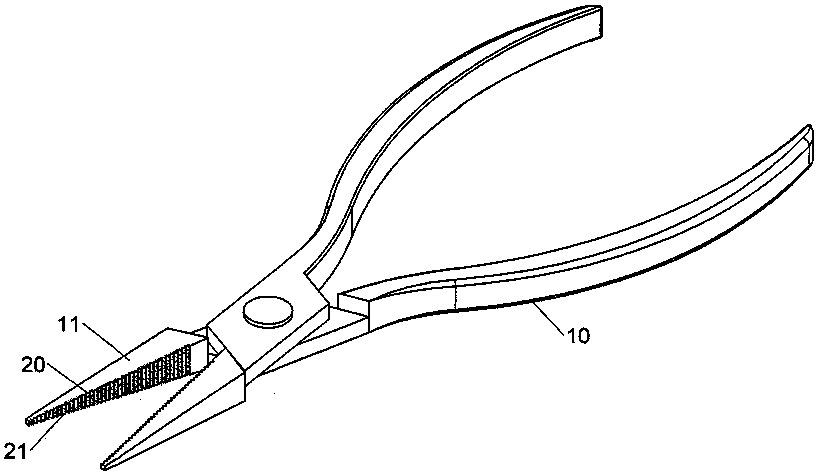

[0056] Embodiment 3

[0057] see image 3 . In this embodiment, the body 10 is a needle nose pliers structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com