Spreader for container lifting

A container and hoisting technology, used in safety devices, transportation and packaging, load hoisting components, etc., can solve problems such as unreliable work, improve reliability, reduce operating costs and maintenance costs, and achieve accurate motion trajectories.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

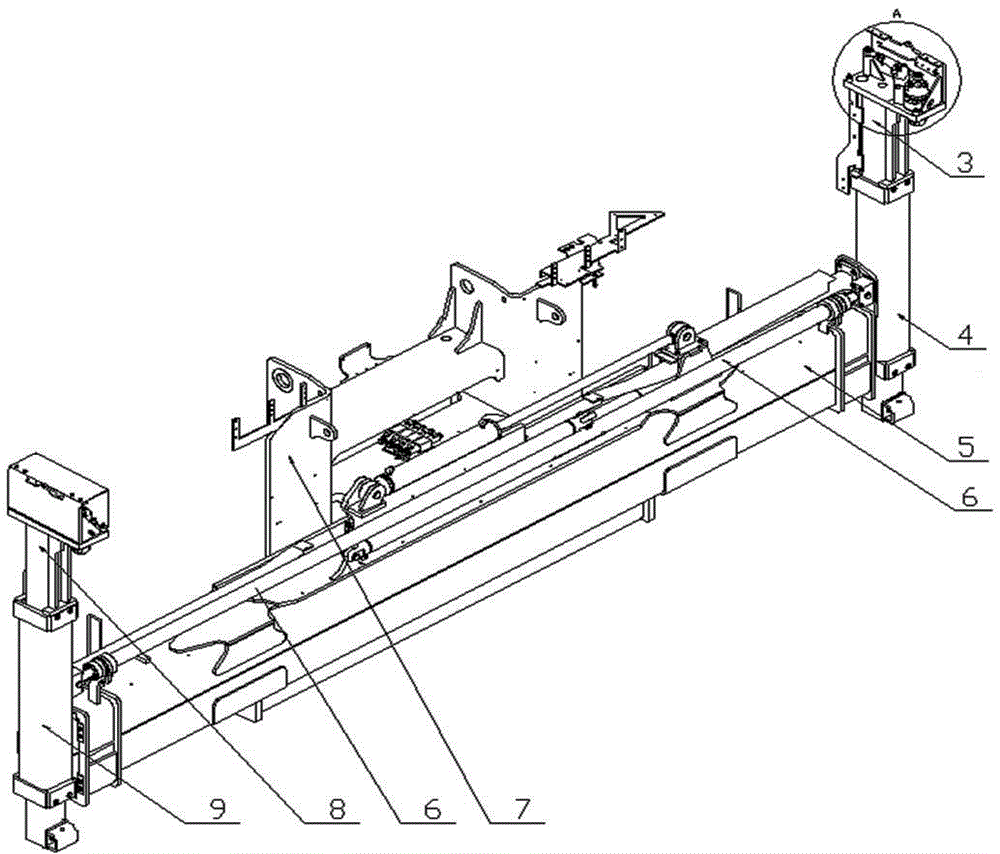

[0030] see figure 1 , the spreader used for container lifting includes a horizontal fixed arm 5, the two ends of the fixed arm 5 are respectively connected with the left telescopic arm 4 and the right telescopic arm 9, the left telescopic arm 4 and the right telescopic arm 9 have the same structure, the left telescopic arm 4 is provided with a left floating arm 3, and a right telescopic arm 9 is provided with a right floating arm 8; the top of the fixed arm 5 is provided with two telescopic oil cylinders 6, and the rear side of the fixed arm 5 is provided with a carriage 7; 6 drives the left telescopic arm 4 to realize moving left and right, and another telescopic oil cylinder 6 drives the right telescopic arm 9 to realize moving left and right.

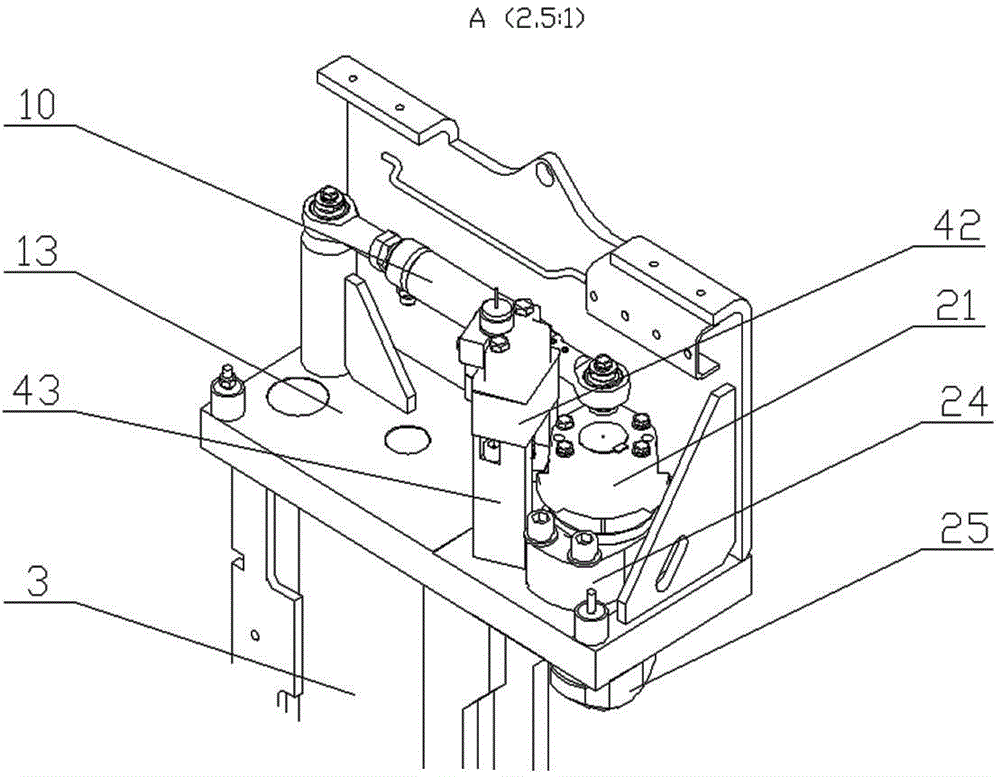

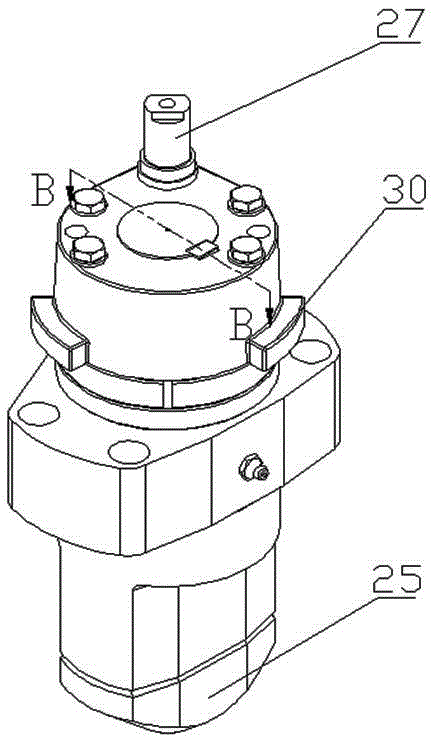

[0031] see figure 2 , image 3 and Figure 4 , the left floating arm 3 and the right floating arm 8 have the same structure, including an upright arm bar, the top of the arm bar is provided with a horizontal mounting plate 13, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com