Structure and method for preventing vertical steel bars from deforming in construction

A vertical steel bar, construction technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of affecting the strength of steel bars, prone to bending, occupying construction work surface, etc., to improve strength and stability, prevent Bending deformation, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiment given with accompanying drawing.

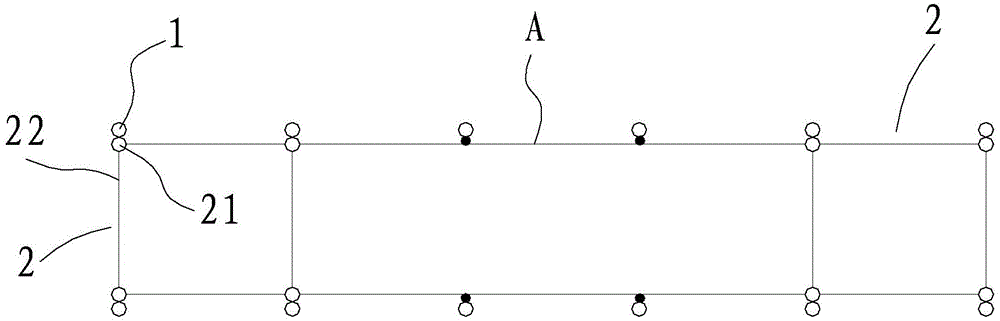

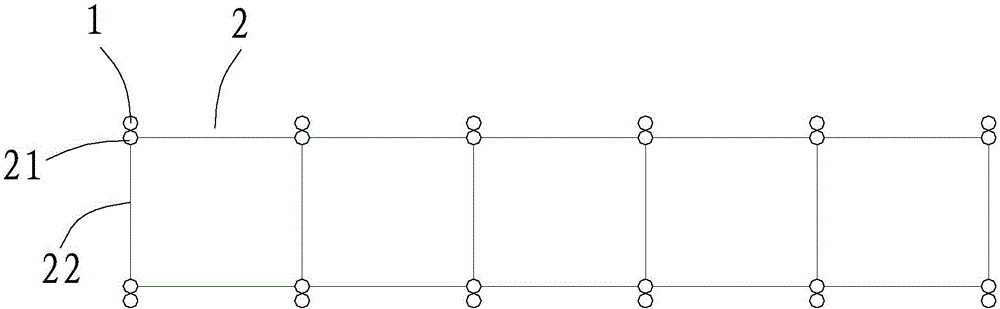

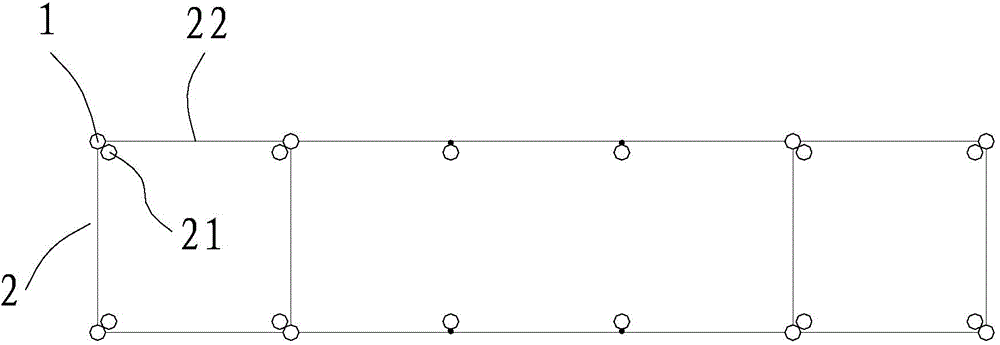

[0024] like Figures 1 to 6 As shown, the present invention provides a structure for preventing deformation of vertical steel bars during construction, which includes several vertical steel bars 1 arranged at intervals in the horizontal direction and brackets 2 for supporting the vertical steel bars 1 . Described support 2 comprises several vertical positioning rods 21 and several connecting rods 22, and each vertical positioning rod 21 is all fixed on a vertical steel bar 1, and when fixing, described vertical positioning rod 21 is by binding, At least two ends are fixedly connected to the corresponding vertical steel bar 1 by clamping or welding, and two adjacent vertical positioning rods 21 are fixedly connected through a connecting rod 22 respectively.

[0025] Preferably, the brackets 2 may be arranged at intervals along the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com