Wall structure of parapet wall and construction method of parapet wall

A technology of wall structure and parapet wall, applied to the wall structure of parapet wall and its construction field, can solve the problems of long construction period, heavy parapet wall, increasing the difficulty of roof waterproofing treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

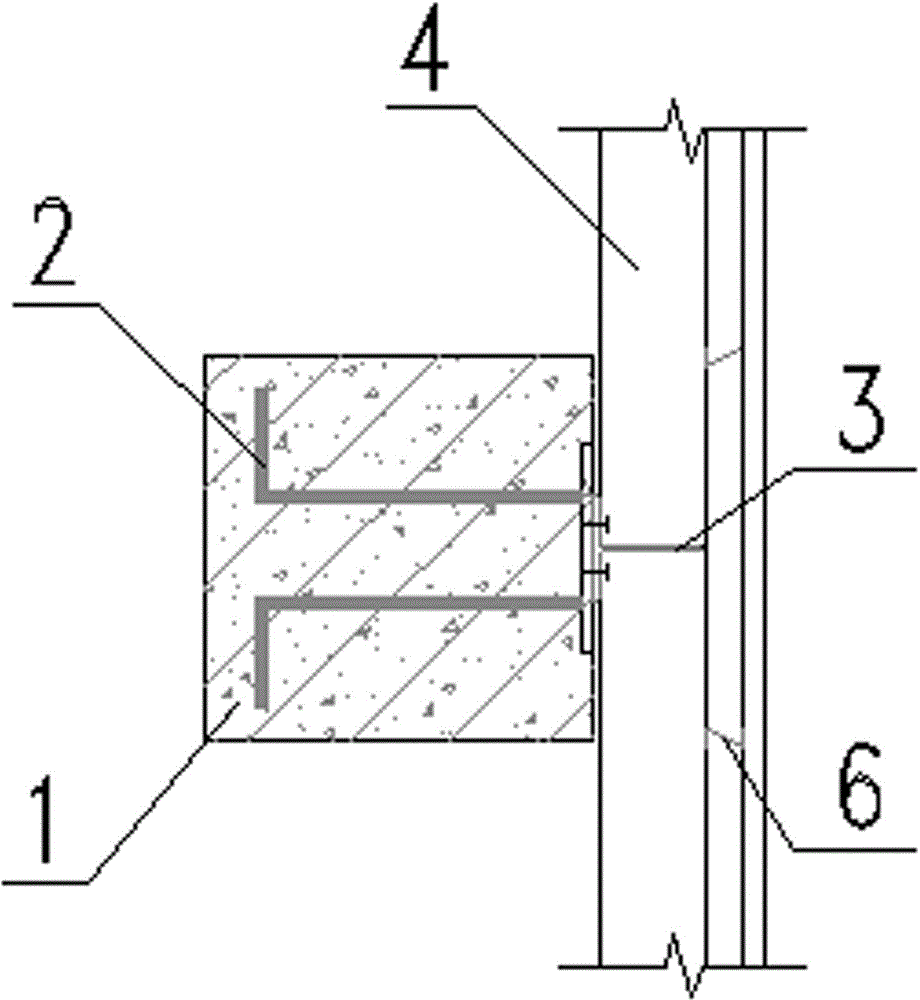

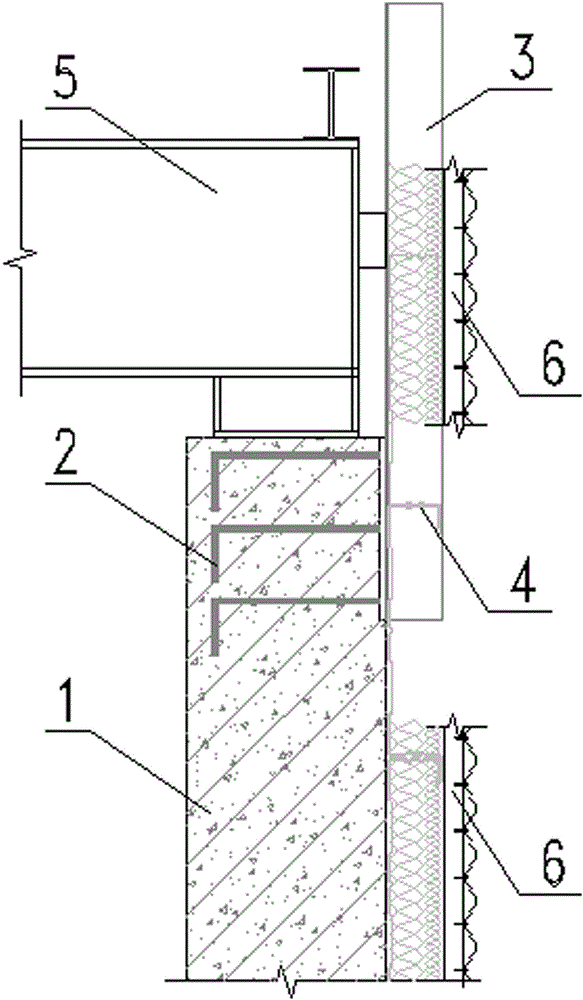

[0026] Please combine figure 1 and figure 2 , a wall structure of a parapet, the wall structure includes a concrete column 1, a parapet column 3, and an inner wall 4, the concrete column 1 is provided with an embedded part 2, and the parapet column 3 is fixed on the embedded part 2, The inner wall 4 is fixed on the parapet column 3 .

[0027] Preferably in this embodiment, the parapet column 3 and the embedded part 2 are welded and fixed. Those skilled in the art can imagine that the parapet column 3 and the embedded part 2 can also be fixedly connected in other ways, and any technical solution that is the same as or similar to the technical concept of the present invention should be covered within the protection scope of the present invention.

[0028] Preferably, the parapet column 3 of this embodiment is a T-shaped hidden parapet column, which is a steel column. That is, the parapet column 3 is a T-shaped hidden steel parapet column.

[0029] The inner wall 4 is fixedl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap