Photocatalyst sunshade body armor

A technology of body armor and photocatalyst, which is applied in the direction of protective equipment, offensive equipment, layered products, etc., can solve the problems of inability to oxidize and decompose surrounding bacteria, viruses and harmful gases, lack of protection, and insufficient comfort of body armor, etc., to achieve improvement Long service life, high protection, and the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

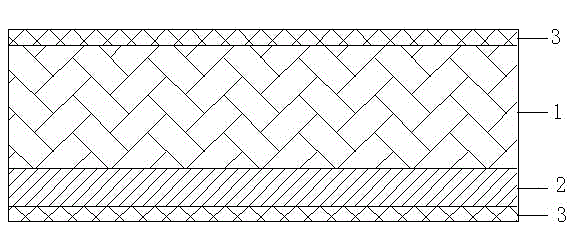

[0010] see figure 1 , the present invention relates to a kind of photocatalyst sunshade flak jacket, and this flak jacket is formed by compounding bulletproof layer 1 and fabric layer 2, and the outside of described bulletproof layer 1 and fabric layer 2 is covered with a layer of clothing cover 3, and described bulletproof layer 1 is made of Five layers of aluminum alloy, fiberglass, nylon, Kevlar (KEVLAR, poly-p-phenylene terephthalamide) and ultra-high molecular weight polyethylene fiber (DOYENTRONTEX Fiber) are closely combined in sequence. It has high protection and can Effective bulletproof and impactproof, the fabric layer 2 is compounded on the side of the bulletproof layer 1 close to the ultra-high molecular weight polyethylene fiber.

[0011] The fabric used in the fabric layer includes a sunshade fabric base material, and a layer of inert adhesive layer is coated on the surface of the sunshade fabric base material to form a film bonding layer, and then a layer of ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com