Vertical type unit axis swing degree measuring and adjusting experimental device and experimental method

An experimental device and axis technology, which is applied in the field of vertical unit installation parameter measurement and adjustment experimental devices, can solve the problems of low adjustment accuracy, poor learning effect, and poor vertical unit axis swing measurement technology, and achieves more projects and training opportunities. The effect of improving the quality of teaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

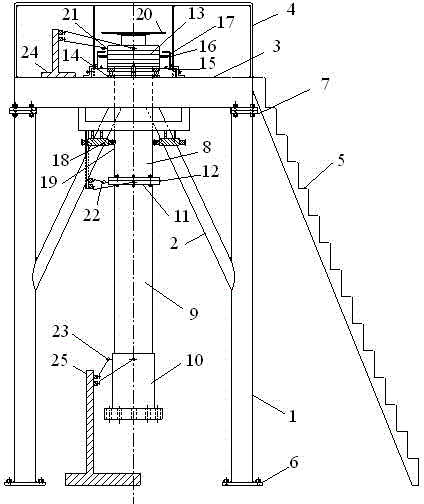

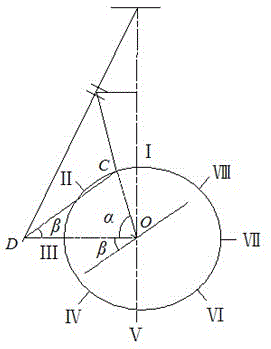

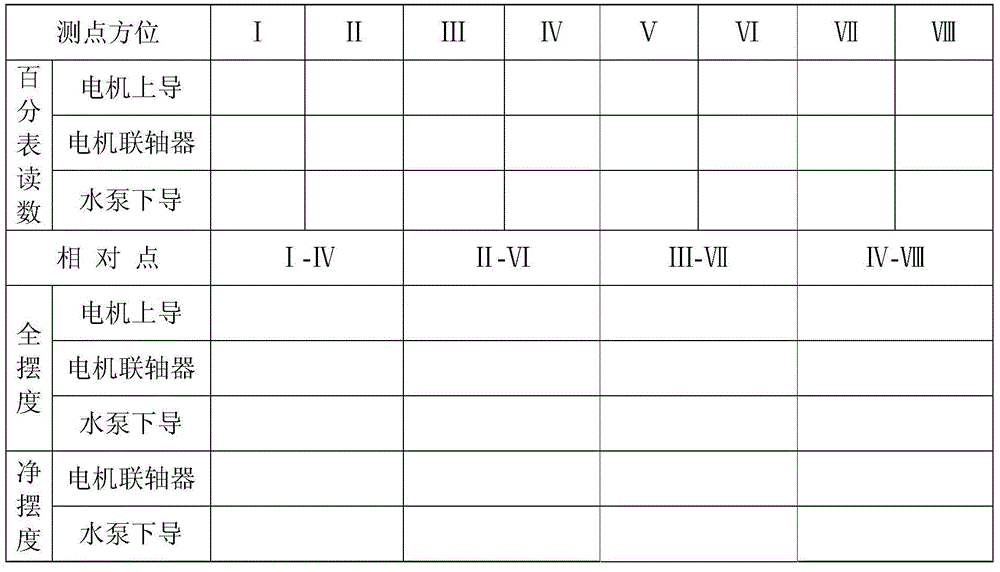

[0024] Embodiment 1 (experiment one)

[0025] When no adjusting shim 15 is added between the thrust bearing 14 and the thrust head 13 and no adjusting shim 12 is added between the rigid coupling 11, measure the remaining swing of the motor shaft 8 and the water pump shaft 9. Record the readings of dial indicator 1 21, dial indicator 2 22 and dial indicator 3 23, and calculate the swing value and its orientation. The remaining swing should be very small and within the acceptable range.

Embodiment 2

[0026] Embodiment 2 (experiment two)

[0027] Add the adjustment gasket 2 15 on the side between the thrust bearing 14 and the thrust head 13, and calculate the swing value and its value at the flange of the rigid coupling according to the thickness of the adjustment gasket 2 15 and the relevant dimensions of the device. position. Measure and calculate the maximum value and azimuth of the swing at the flange of the rigid coupling with the dial gauge 222, and compare and analyze with the calculated predicted value.

Embodiment 3

[0028] Embodiment 3 (experiment three)

[0029] No adjusting shim 15 is added between the thrust bearing 14 and the thrust head 13, and an adjusting shim 12 is added on the end face side of the rigid coupling 11 between the water pump shaft 9 and the motor shaft 8, and the thickness of the shim 12 is adjusted according to the addition And the related dimensions of the device, calculate and predict the swing value and orientation that the pump shaft journal should have. Use dial gauge 3 23 to measure and calculate the maximum value and orientation of the swing at the journal of the water pump shaft, and compare and analyze with the calculated value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com