Peeling device for continuous soaking materials

A peeling device and material technology, applied in the fields of food science, shelling, pod removal, etc., can solve the problems of low production efficiency, no continuous peeling device, unsuitable for industrial production, etc., so as to improve production efficiency, improve peeling effect, noise small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

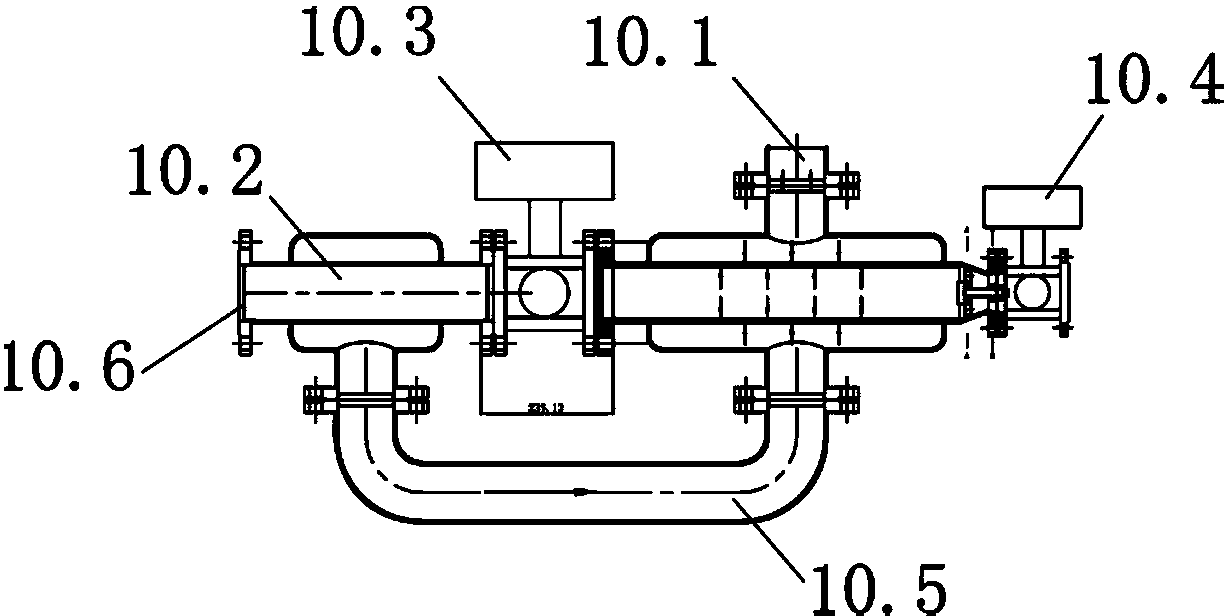

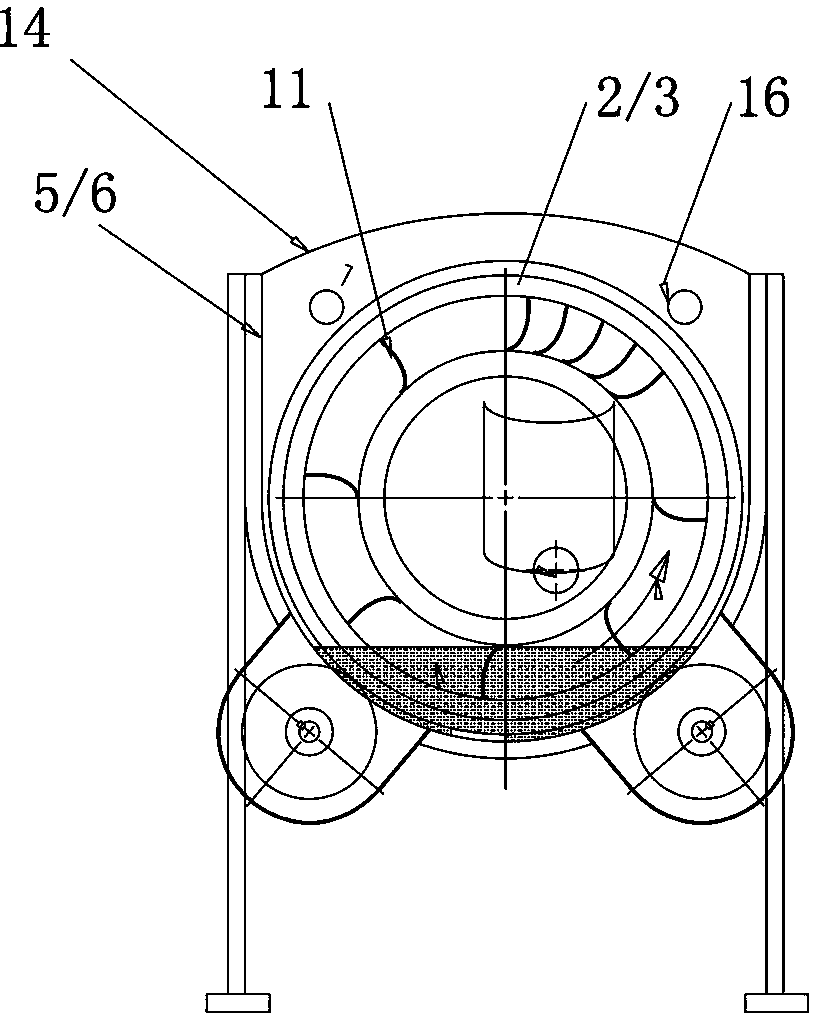

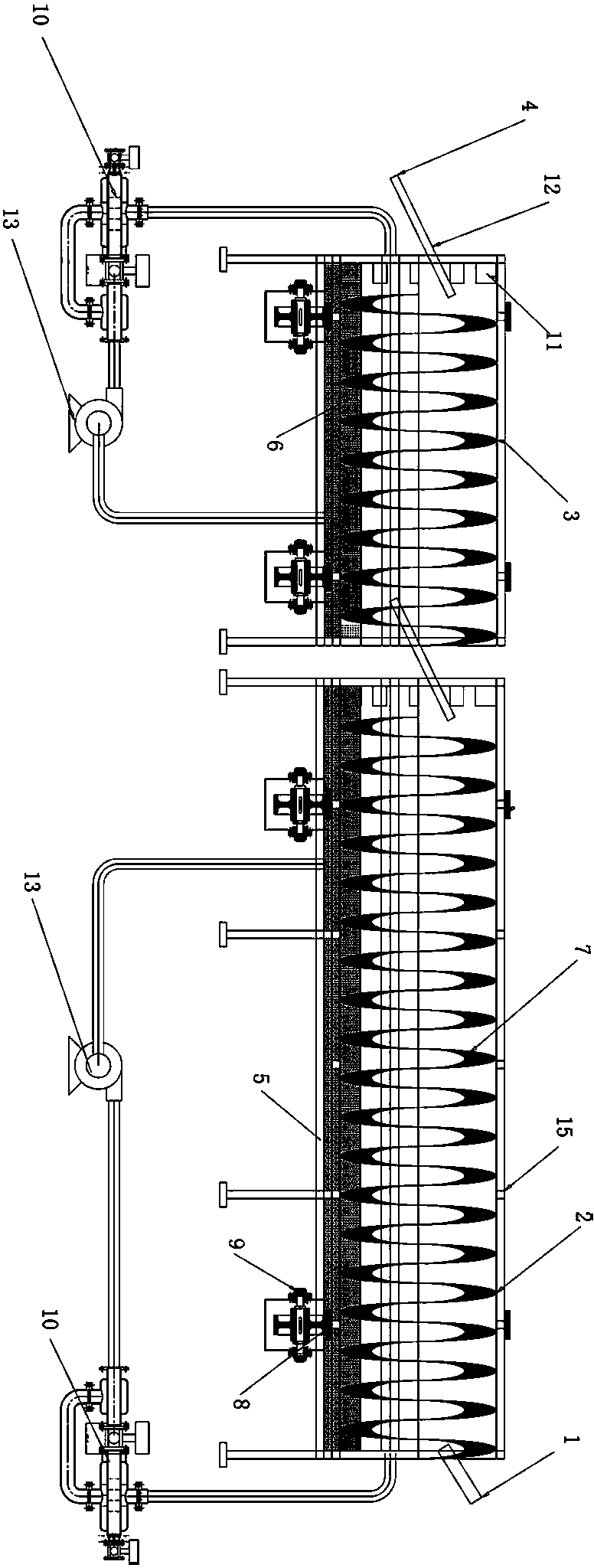

[0012] Such as figure 1 As shown, this embodiment is a continuous soaking material peeling device, including a material inlet 1 to be peeled, a peeling screw drum 2, a cleaning screw drum 3, a peeled material outlet 4, a peeling screw drum 2 and a cleaning screw drum 3 arranged in sequence They are placed in the first circulating water tank 5 and the second circulating water tank 6 respectively, and are driven to run by transmission devices arranged outside the first circulating water tank 5 and the second circulating water tank 6 respectively. The peeling spiral drum 2 and the first circulating water tank 5 form a peeling device, and the cleaning spiral drum 3 and the second circulating water tank 6 form a cleaning device. The peeling spiral drum 2 has a mesh, and its inner wall is provided with a spiral belt 7 . The first circulating water tank 5 has a thermal insulation layer and contains medicament (such as lye), and the water level height will be lower than the height of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com