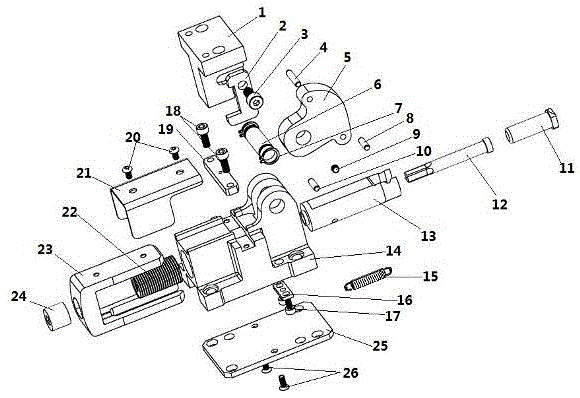

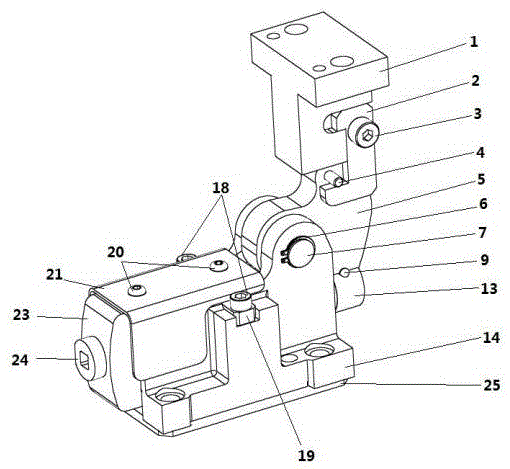

A light-load side impact mechanism

A light-load, punch technology, applied in the field of mold components, can solve the problems of increased cost and large overall structure of the mold, and achieves the effect of small occupied space, reduced mold structure, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0020] The specific embodiment is as follows: when the stamping starts, the force of the downward movement produced by the punch press acts on the drive block 1, and the drive block 1 moves downward, pressing the swing crank 5 downward, because the swing crank 5 is hinged on the lower base through the swing crank shaft 6 14, so the swing crank 5 rotates around the swing crank shaft 6, and the swing crank 5 lower end pushes the punch push rod 11 to the left, and the punch push rod 11 promotes the punch 12 and the punch cover 13 which are fixed in series with it to move together. The left end of the punch cover 13 promotes the pressing material spring 22 connected in series, the discharge cover guide plate 23 and the discharge cover 24 to move to the left together. When the left end surface of the unloading sleeve 24 began to touch the material to be punched, the pressing spring 22 began to be compressed, and the material to be punched began to be flattened; when the punch 12 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com