Method for moving casting mold on casting line in V-process casting production

A technology of casting production and pouring line, which is applied in the field of realizing the movement of casting molds through automated equipment, which can solve problems such as manual operation instability, and achieve the effects of low production efficiency, improved automation level, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

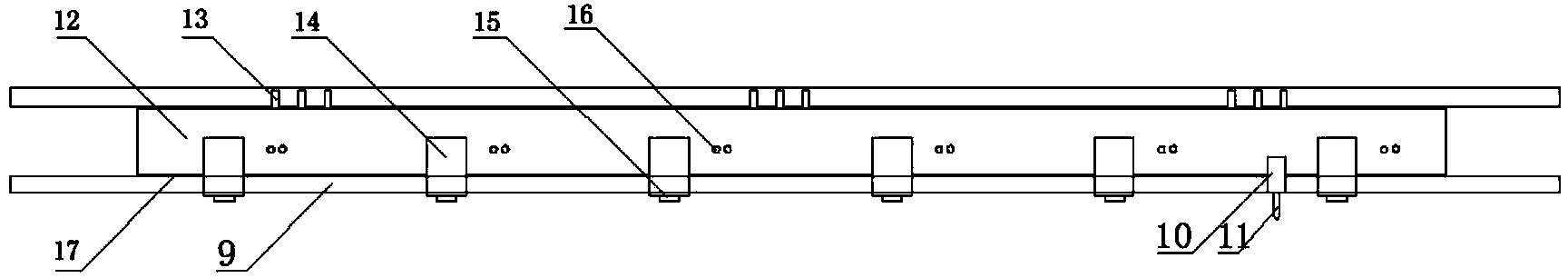

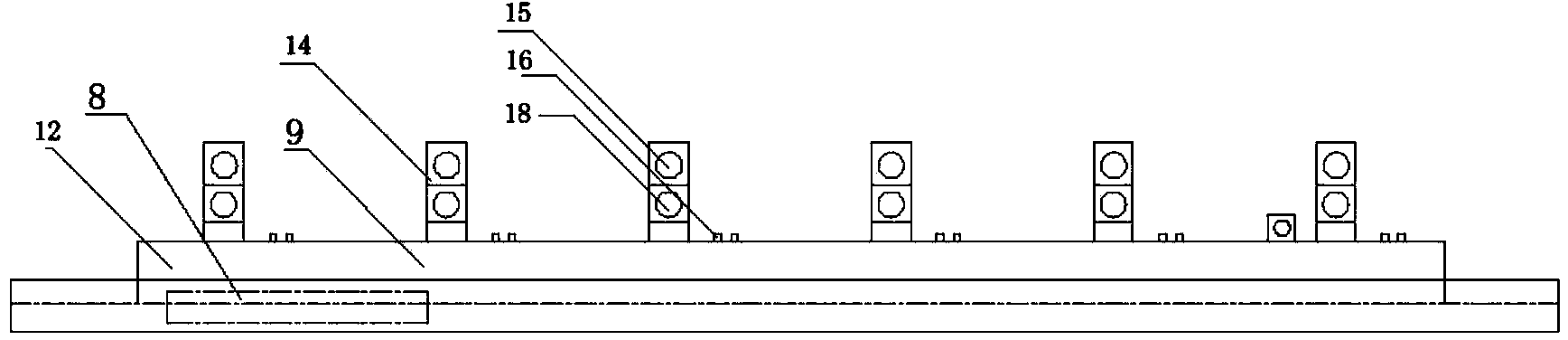

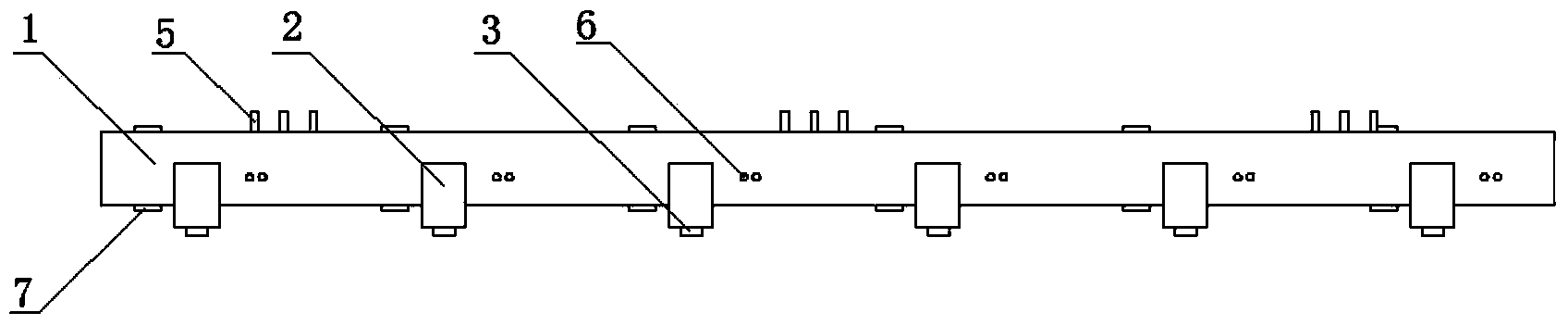

[0047] 【1】After the casting mold is completed, it is transferred to the pouring line by the pouring transfer vehicle. At this time, the vacuum interface on the fixed vacuum beam moves under the control of the cylinder until it is connected with the vacuum interface on the sand box to provide vacuum for the mold.

[0048] [2] Move the vacuum beam back to the initial position, the vacuum interface on the moving vacuum beam is connected to the vacuum interface on the sand box through the cylinder control, and the pin on the moving vacuum beam is connected to the hole on the moving base plate through the cylinder control.

[0049] 【3】The vacuum interface on the fixed vacuum beam is disconnected from the vacuum interface on the sand box under the control of the cylinder.

[0050] 【4】The moving vacuum beam moves forward under the control of the end cylinder, and the power is provided by the pin to push the moving bottom plate and the mold to move forward along the pouring roller tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com