General assembly table for tank container

A technology of tank container and final assembly platform, which is applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of crowded workers, difficulty in improving assembly efficiency, poor working environment, etc., so as to improve the working environment and improve assembly efficiency. , the effect of increasing the space for personnel activities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

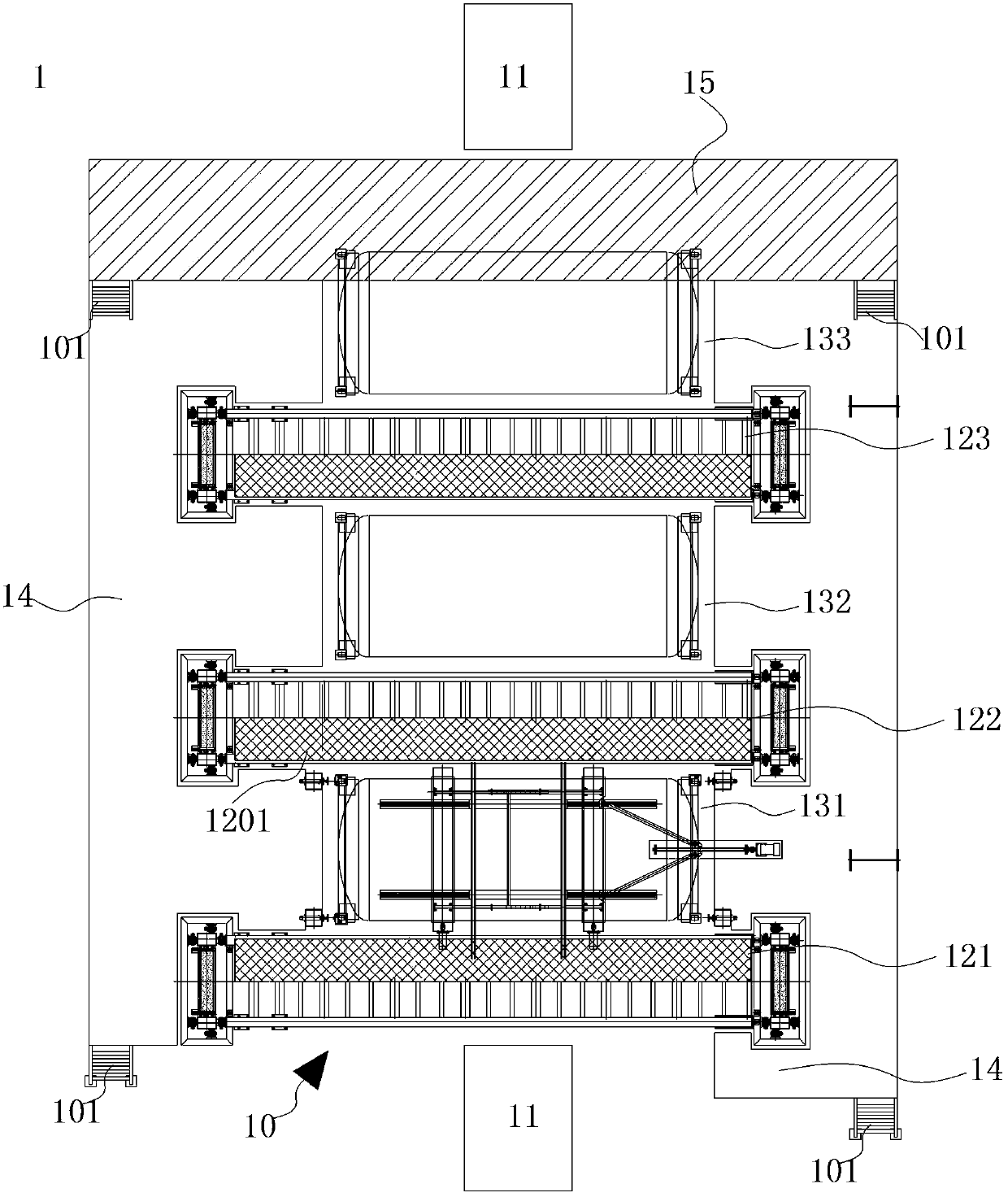

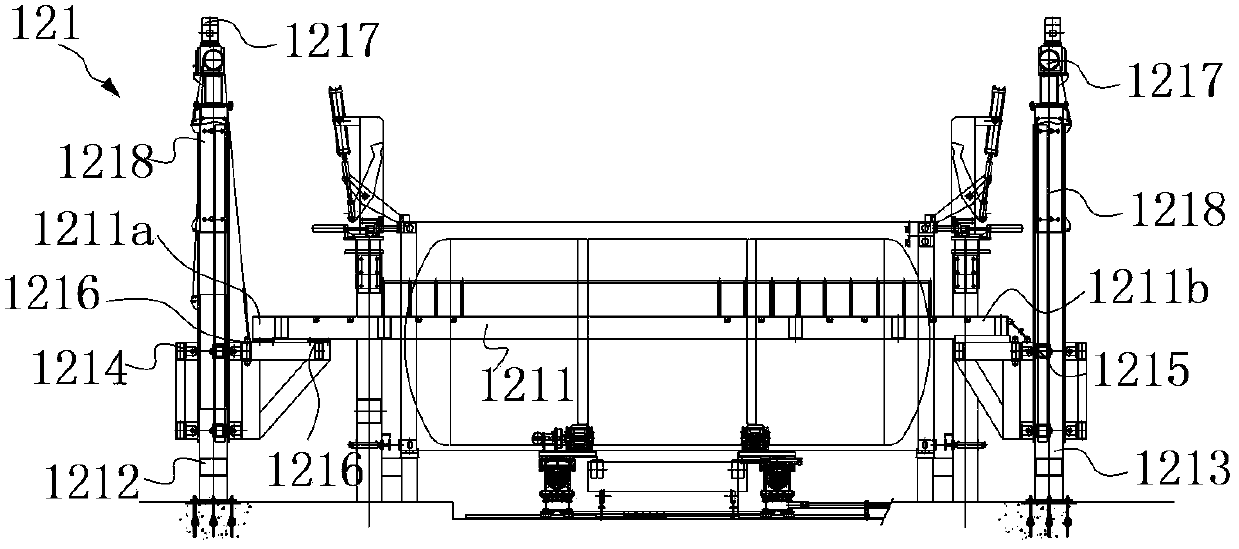

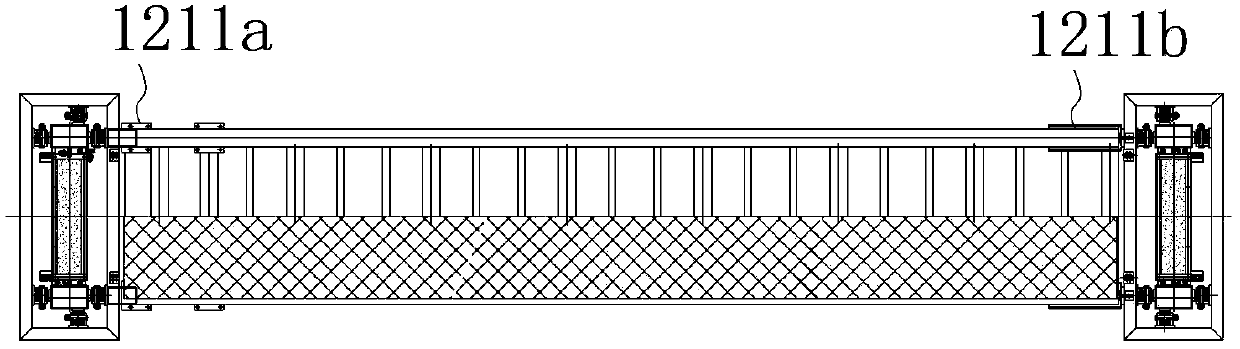

[0029] see figure 1 with figure 2 , figure 1 It is a top view structure schematic diagram of the tank container assembly platform of the present invention, figure 2 It is a schematic diagram of the side structure of the tank container assembly platform of the present invention. The tank container assembly platform 1 of the present invention is used to assemble and weld the cylinder body 31 and the end frames, top side beams, bottom side beams and other components according to technical requirements, or directly process the cylinder body 31 itself, for example, overflow Flow box grinding and matching operation, bottom discharge hole pressing operation. The tank container assembly platform 1 includes an assembly area 10, a plurality of lifting platforms arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com