Handle assembly and electric tool using same

A technology of electric tools and components, applied in cutting tools, hand-held tools, manufacturing tools, etc., can solve the problem that the holding method cannot be used universally, and achieve the effect of avoiding secondary development and realizing electrical connection or disconnection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

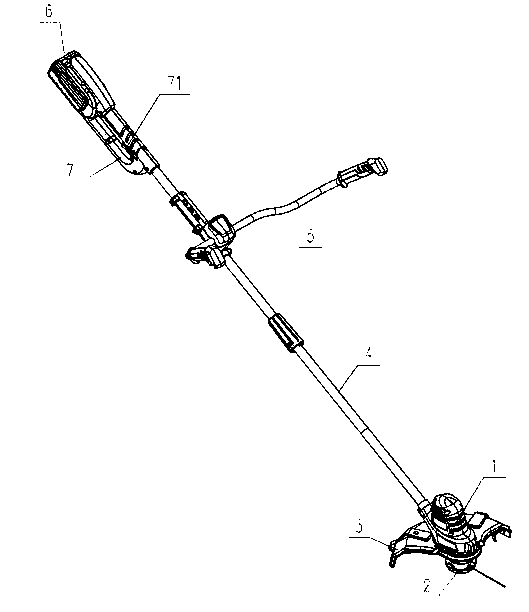

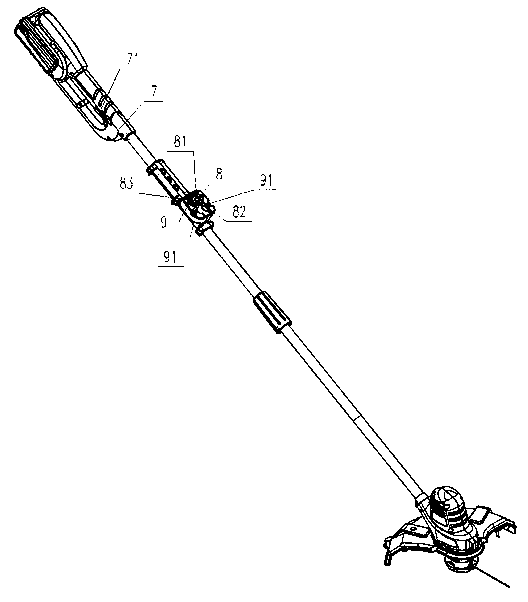

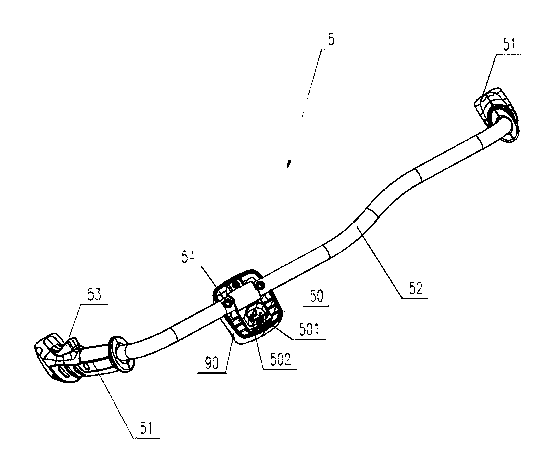

[0022] Such as figure 1 Shown is a schematic diagram of an electric tool according to an embodiment of the present invention, which is a mowing machine, which includes a body and a handle assembly, the handle assembly includes a first auxiliary handle 5, the body includes a connecting pipe 4, and one end of the connecting pipe 4 is provided A machine head 1 is provided with a motor inside the machine head 1, and a working head 2 is arranged below the machine head 1, and the motor drives the working head 2 to perform operations. The rear portion of the working head 2 is provided with a protective cover 3 to prevent the gravel flying from the ground from injuring the rear user during work. The other end of the connecting pipe 4 is provided with a power source 6 to provide working power for the machine head. The power source 6 in this embodiment is a battery. A handle 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com