A machine room-less elevator device

A machine room-less elevator, the same technology, applied in elevators, textile cables, transportation and packaging, etc., can solve the problems of increasing construction and installation costs, increasing the size of the top space of the well, and achieving the effect of reducing the wrap angle and reducing the height of the top floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

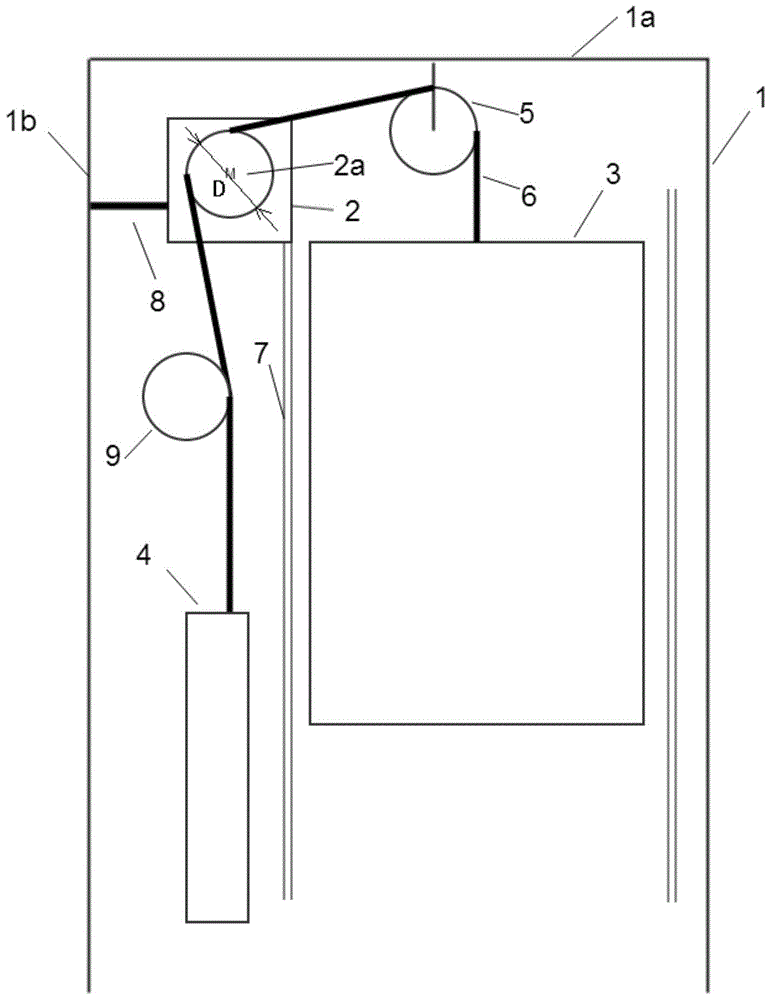

[0040] Such as figure 1As shown in the figure, in the machine room-less 1:1 elevator device shown in the figure, in the hoistway 1, the traction machine 2 is installed on the car guide rail 7 on one side, and is connected to the side wall 1b of the hoistway through the auxiliary bracket 8 at the same time. In order to reduce the vibration to the side wall 1b of the hoistway, rubber is used to insulate between the auxiliary bracket 8 and the side wall 1b of the hoistway.

[0041] The car 3 and the counterweight 4 are connected together by a traction rope 6 and hung on the traction sheave 2a and the guide sheave 5 . The traction wrap angle between the traction rope 6 and the traction wheel 2a is realized by adjusting the traction wheel 2a and the guide wheel 5, and is controlled at 70-120°. In order to minimize the height of the top floor, the traction wrap angle is preferably at 80°~90°. In order to reduce the height of the top floor of the hoistway as far as possible, the gu...

Embodiment 2

[0052] The difference of the machine-room-less 1:1 elevator device in this embodiment is that the structure of the traction rope 6 is different, and the rest of the structures are the same.

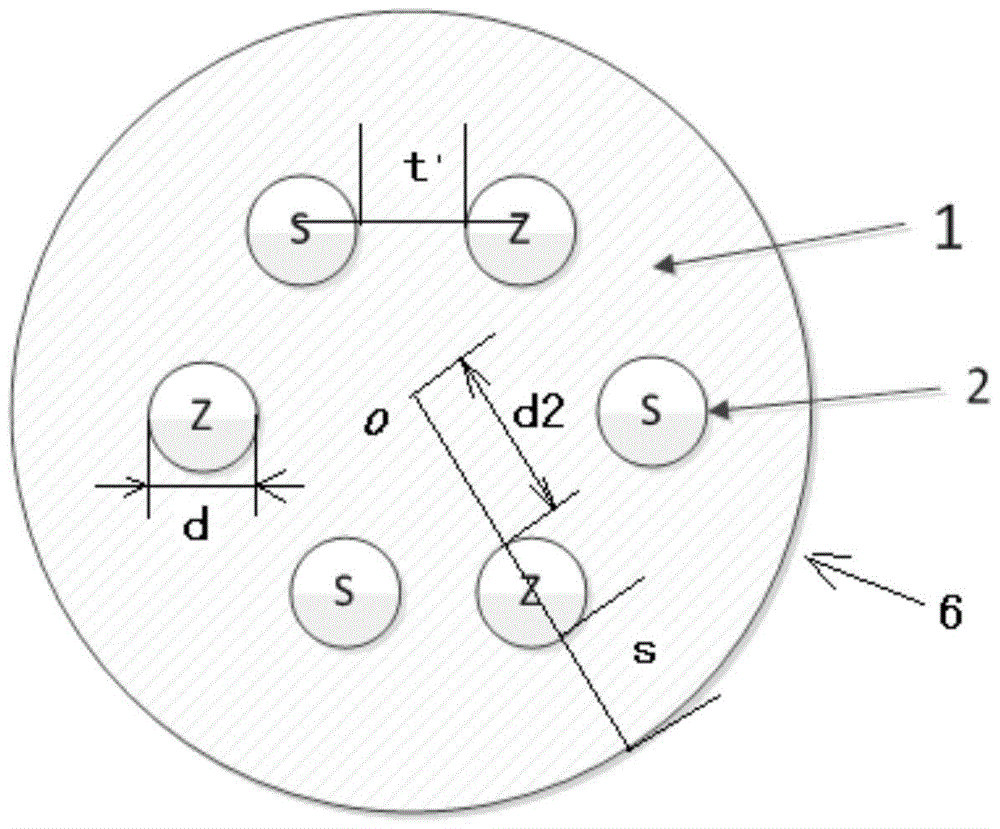

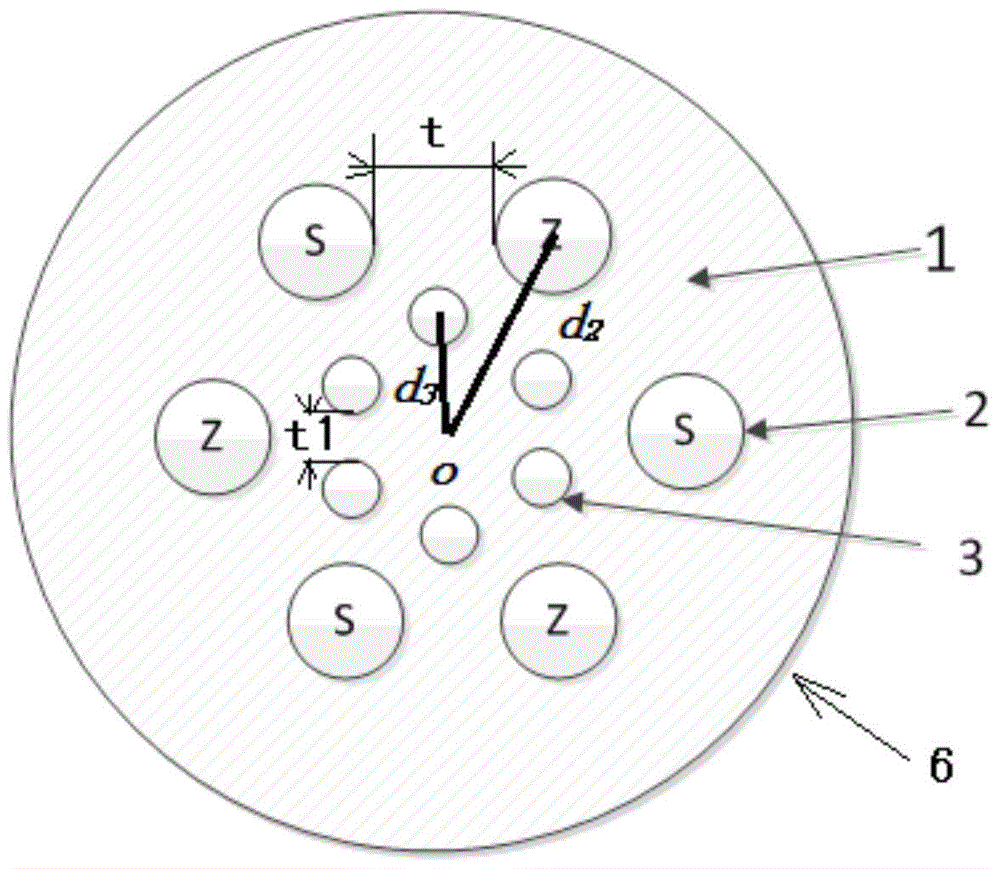

[0053] In order to increase the breaking force of the traction rope and provide support for the independent carrier 2 of the outer layer, such as figure 2 As shown, all the independent bearing bodies in this embodiment are distributed in two concentric circles in the radial direction in the elastic body 1 constituting the traction rope body, and the independent bearing bodies of each layer are evenly distributed on the same circumference, considering the compactness of the structure , the diameter of the independent carrier 3 of the inner layer is smaller than the diameter of the independent carrier 2 of the outer layer, and every two adjacent independent carriers 3 in the independent carrier 3 of the outer layer are evenly spaced on the same circumference and constitute the traction rope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com