Anticorrosion paint primer-finish composition

A technology of anti-corrosion coatings and compositions, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient chemical resistance and affecting curing speed, etc., achieve excellent construction performance, prevent internal stress corrosion, penetration The effect of wetting solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

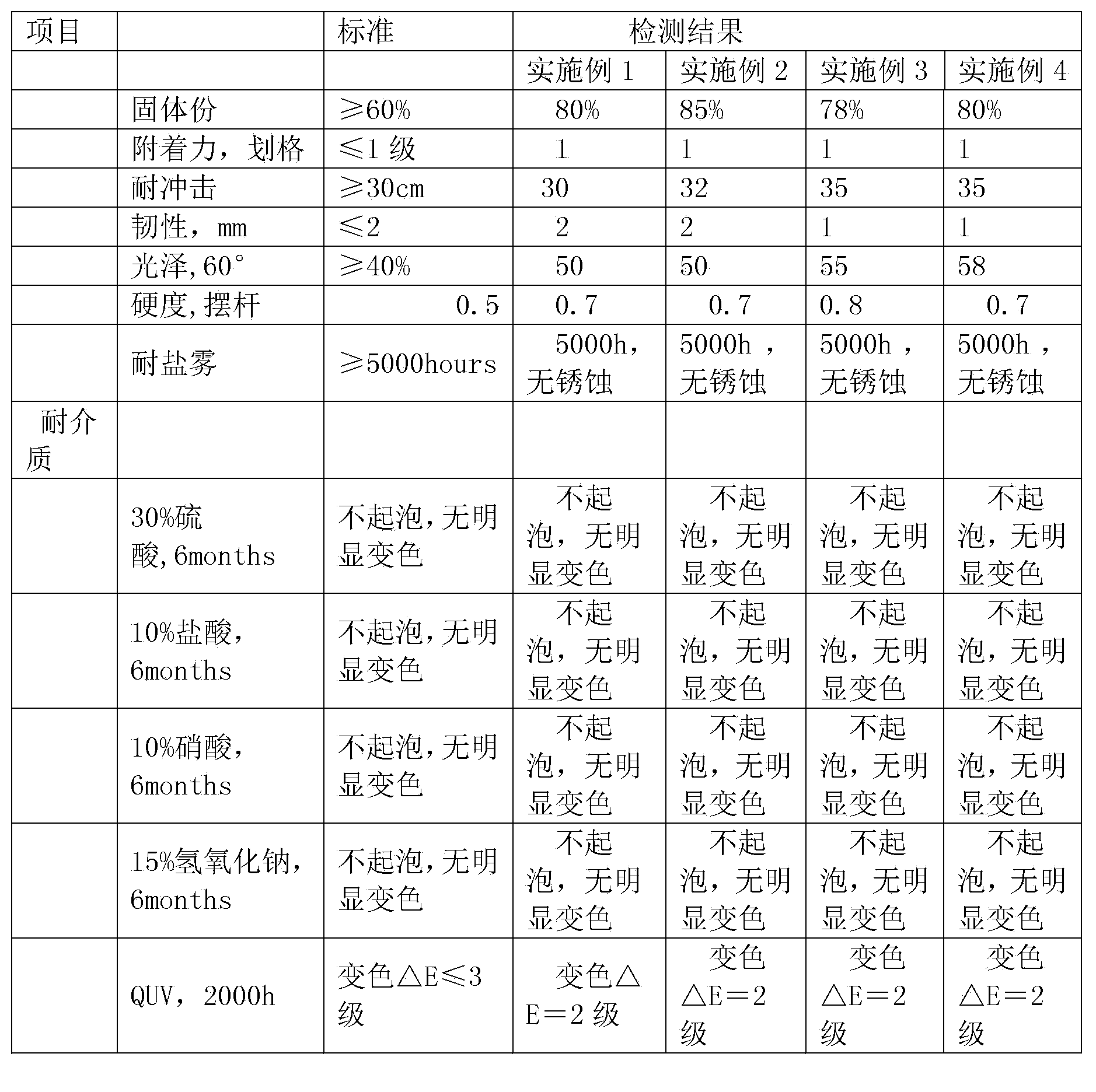

Examples

Embodiment 1)

[0041] (1) Primer preparation A component: weigh 2.2 kg of hydroxyl acrylic resin; 0.46 kg of polyaspartic acid resin; 0.05 kg of dispersant; 0.5 kg of washing water, polymethacrylate: xylene volume ratio 1:1 mixture; anti-settling agent 0.1 kg organic bentonite and gas phase method sio 2 0.05 kg each; 0.06 kg leveling agent; 2 kg antirust pigment; 0.1 kg coloring pigment; 1 kg titanium dioxide; 0.4 kg polymethacrylate; 1 kg 1250 mesh talcum powder; 0.6 kg was emulsified by an emulsifier, and then stirred evenly by a high-speed mixer to obtain component A.

[0042] Primer B component aliphatic polyisocyanate 1kg is Bayer N3390.

[0043] (2) Component A of topcoat: weigh 3 kg of hydroxyl acrylic resin; 1 kg of polyaspartic acid resin; 0.05 kg of dispersant; : 1 mixture; anti-settling agent 0.1 kg is organic bentonite and gas phase method sio 2 0.05 kg each; 0.15 kg leveling agent; 0.1 kg polymethacrylate; 3 kg titanium dioxide; 0.5 kg 1250 mesh sericite; 0.8 kg barium sulfat...

Embodiment 2)

[0046] (1) Primer preparation A component: weigh 2.2 kg of hydroxyl acrylic resin; 0.46 kg of polyaspartic acid resin; 0.05 kg of dispersant; 0.5 kg of washing water, polymethacrylate: xylene volume ratio 1:1 mixture; anti-settling agent 0.1 kg organic bentonite and gas phase method sio 20.05 kg each; 0.06 kg leveling agent; 2 kg antirust pigment; 0.1 kg coloring pigment; 1 kg titanium dioxide; 0.4 kg polymethacrylate; 1 kg 1250 mesh talcum powder; 0.6 kg; when the temperature is low in autumn and winter, component A also includes 1.7 parts of catalyst, including organotin catalyst 1%TT 0.1 kg from Deqian Company, modified amine catalyst Shanghai Huarong Chemical Co., Ltd. 5%PP 0.07 kg, passed through an emulsifier After emulsification, stir evenly with a high-speed mixer to obtain component A.

[0047] Primer B component aliphatic polyisocyanate 1kg is Bayer N3390.

[0048] (2) Component A of topcoat: weigh 3 kg of hydroxyacrylic resin; 1 kg of polyaspartic acid resin; 0.05...

Embodiment 3)

[0051] (1) Primer preparation A component: weigh 1.5 kg of hydroxyl acrylic resin; 0.2 kg of polyaspartic acid resin; 0.02 kg of dispersant; 0.2 kg of washing water, polymethacrylate: xylene volume ratio 1:1 mixture; anti-sedimentation agent 0.05kg organic bentonite and gas phase method sio 2 0.025 kg each; 0.03 kg leveling agent; 1 kg antirust pigment; 0.05 kg coloring pigment; 0.55 kg titanium dioxide; 0.4 kg polymethacrylate; 0.6 kg was emulsified by an emulsifier, and then stirred evenly by a high-speed mixer to obtain component A.

[0052] Primer B component aliphatic polyisocyanate 1kg is Bayer N3390.

[0053] (2) Component A of topcoat: weigh 1kg of hydroxyl acrylic resin; 0.5kg of polyaspartic acid resin; 0.01 kg of dispersant; 1 mixture; anti-sedimentation agent 0.06 kg is organic bentonite and gas phase method sio 2 Each 0.03 kg; leveling agent 0.012 kg; solvent polymethacrylate 0.1 kg; titanium dioxide 1 kg; filler 1250 mesh sericite 0.6kg; filler barium sulfate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com