Thin jack device for bridge lifting

A jack, jacking technology, applied in the direction of lifting device, bridge, bridge construction, etc., can solve problems such as failure of jack support, chain reaction, and increased force on construction trailers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

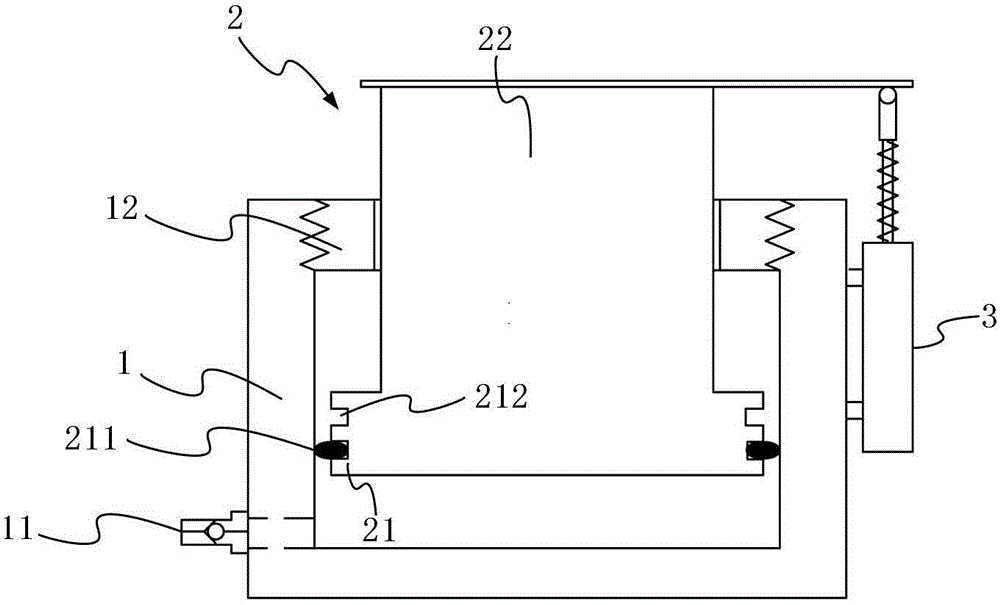

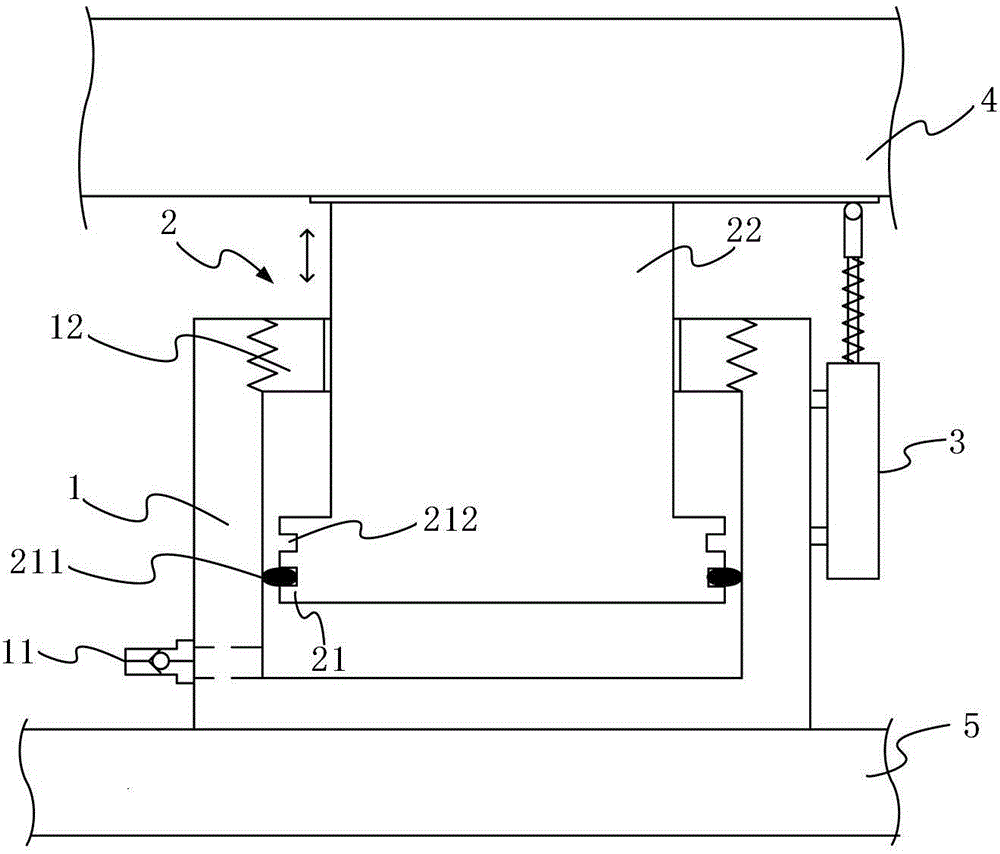

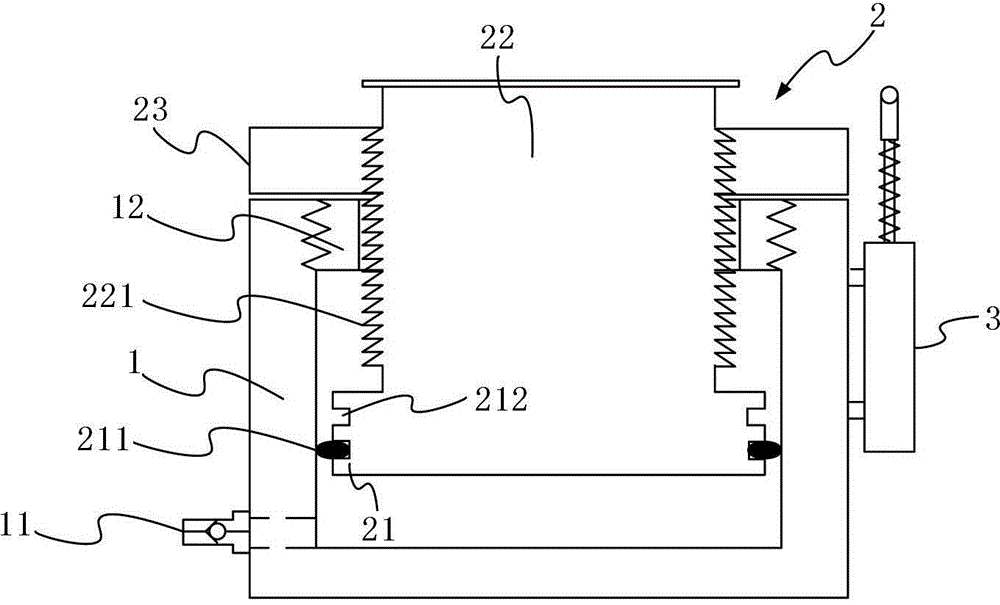

[0025] see figure 1 and figure 2 As shown in FIG. 1 , they are the schematic diagram of the cross-sectional state of the first embodiment of the present invention and the schematic diagram of the use state of the first embodiment of the present invention. As shown in the figure: the present invention is a thin jack device for lifting a bridge, which is at least composed of a base 1 , a jacking unit 2 and a stroke displacement sensor 3 .

[0026] The above-mentioned base 1 is a hydraulic cylinder, and one side of the base 1 is communicated with a check valve 11, and one end of the base 1 is provided with an anti-shock unit ringed on the outer periphery of the jacking unit 2 12.

[0027] The jacking unit 2 is movably combined with the base 1, and the jacking unit 2 includes a limiting part 21 located in the base 1, and an anti-shock unit 12 provided on the end surface of the limiting part 21 and extending out of the base 1 The cylinder 22, wherein the limit portion 21 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com