Concrete continuity monitoring based pile foundation quality discrimination method and monitors

A concrete and monitor technology, applied in the field of concrete pouring, can solve problems such as high cost, multiple judgments, and large losses, and achieve the effects of saving labor, time, and cost, simple and convenient use, and reliable conclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

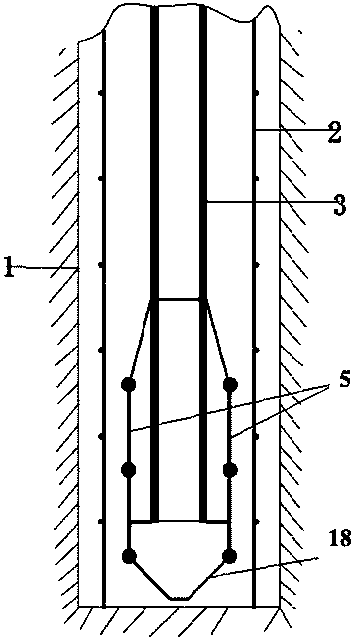

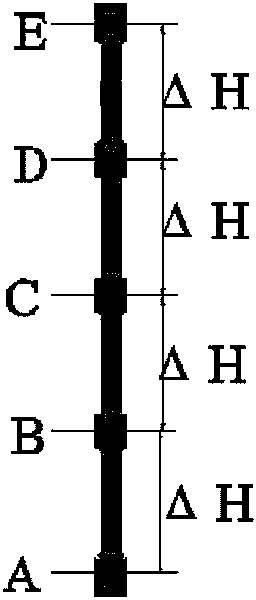

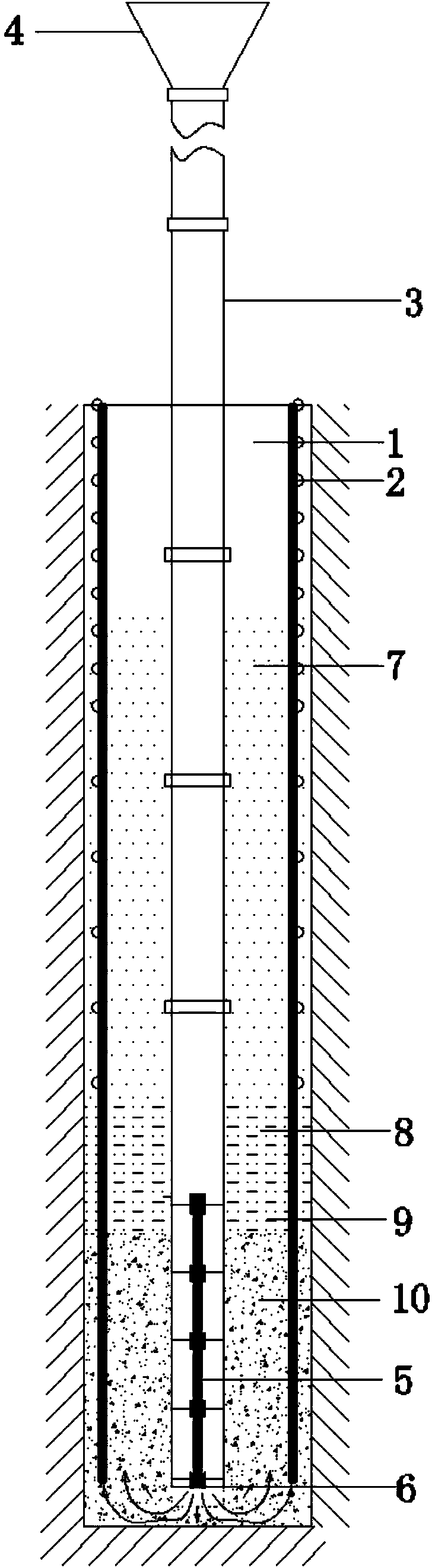

[0035] Such as figure 1 For the cast-in-situ pile in the project shown, the pile hole 1 is put into the reinforcement cage 2, and then extends into the feeding conduit 3; the bottom of the conduit 3 is provided with a conduit port 6 for discharging materials; the top is provided with a hopper 4 for feeding material. During construction, extend the conduit 3 into the reinforcement cage 2, stop at a certain distance from the bottom of the pile hole, inject material through the hopper 4, and then form multiple fluid layers at the bottom of the pile hole 1 from bottom to top: continuous flow Concrete layer 10, mixed layer 9 of mud and concrete, mud water 8 and water 7; after the initial pouring, continue feeding and pouring, the conduit 3 is slowly lifted, and the concrete pouring of the entire pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com