Method and device for stabilizing well wall in fine managed pressure drilling

It is a technique for managing pressure drilling and stabilizing the borehole wall. It is applied in the direction of wellbore/well components, earthwork drilling and production, etc. It can solve the problems of narrowing, weakening, spraying, leaking, collapse, and sticking of the safe drilling fluid density window, and achieves maintenance The effect of wellbore stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

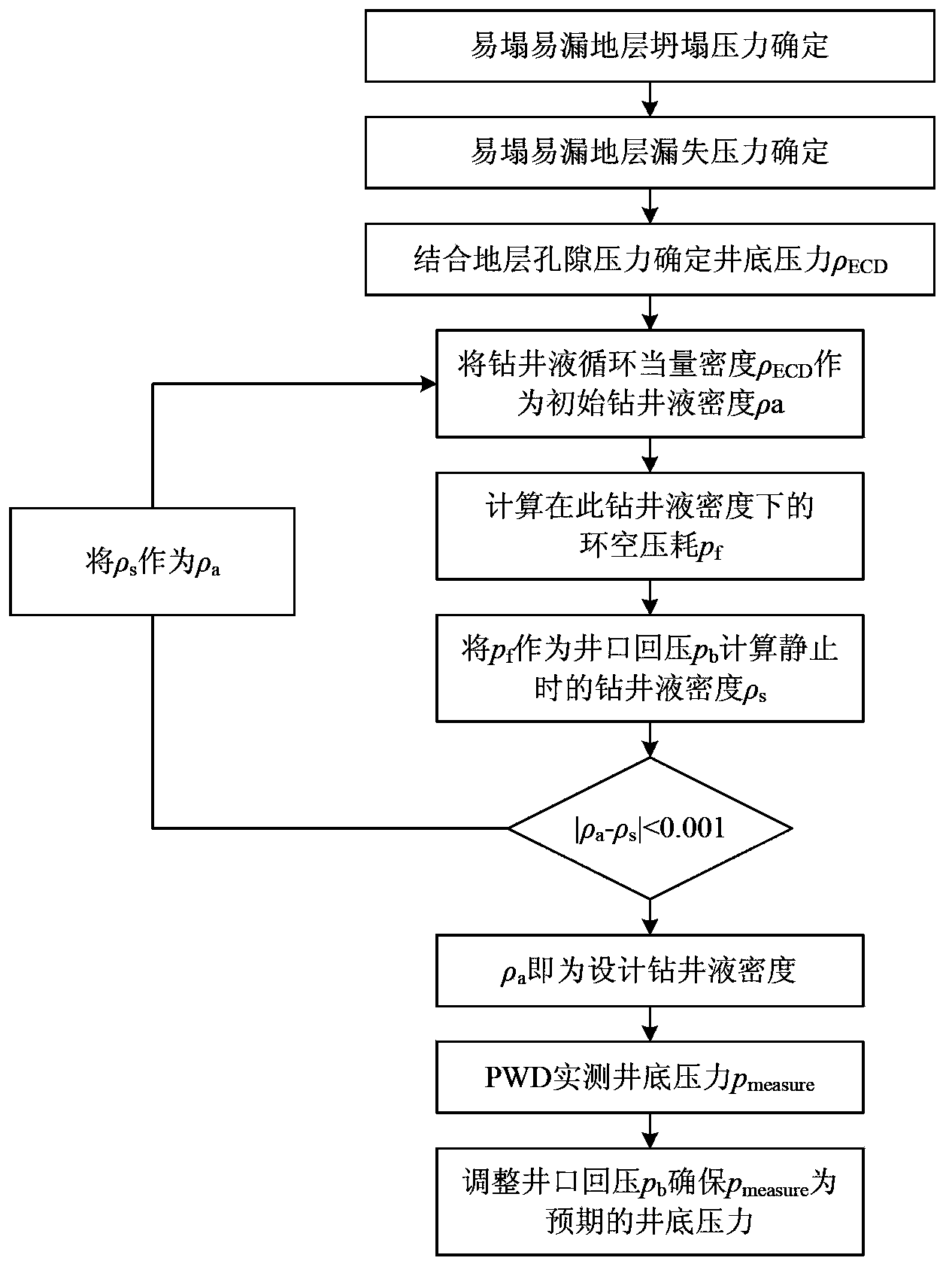

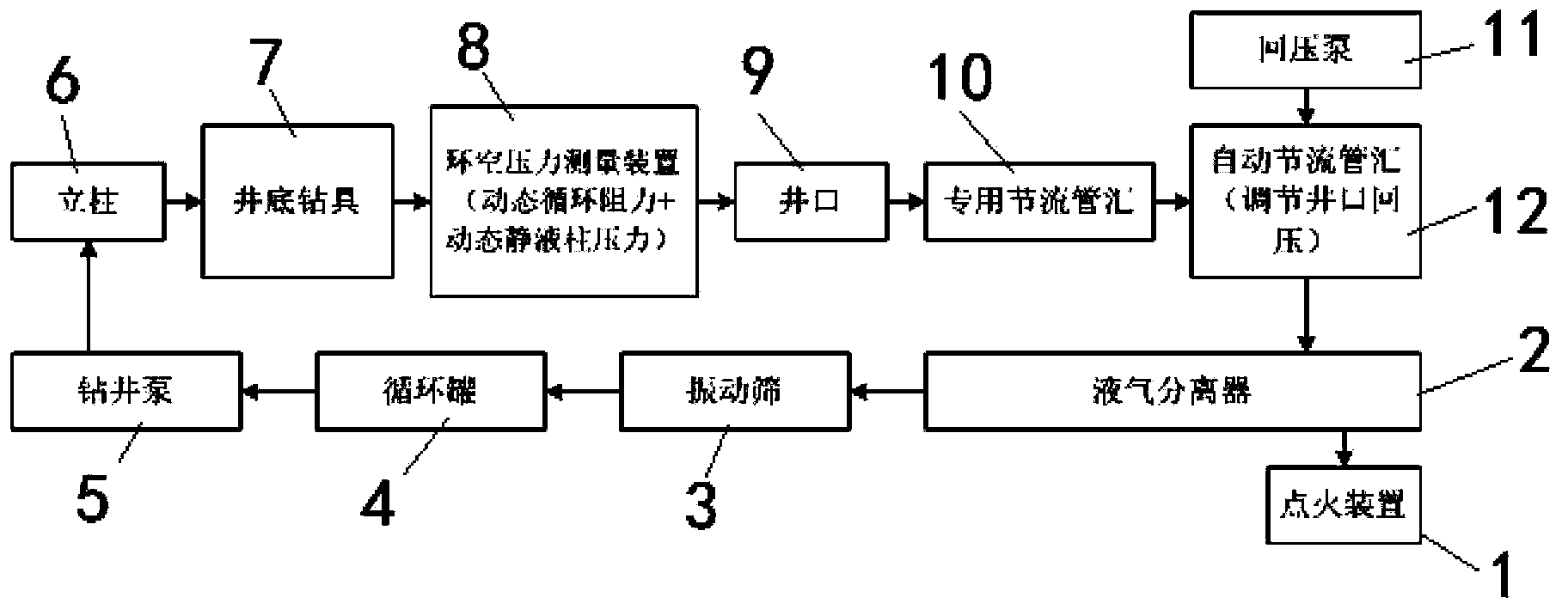

[0022] Embodiment 1: as figure 1 , figure 2 as shown,

[0023] A kind of fine managed pressure drilling method that the present invention proposes to stabilize the borehole wall, the steps are as follows:

[0024] ①Determine the collapse pressure and leakage pressure of the easy-to-collapse interval;

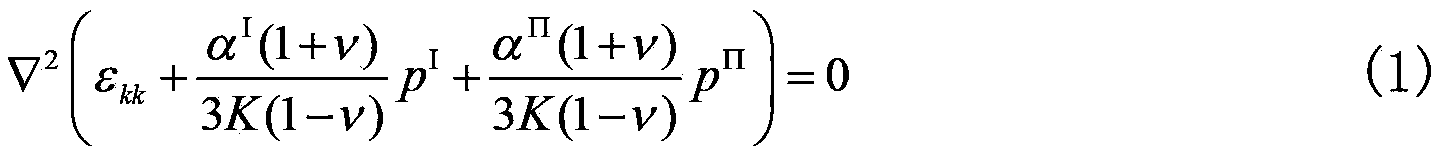

[0025] Combining the dual medium constitutive equation with the stress balance equation and the geometric equation, the formation field equation that is prone to leakage and collapse is obtained.

[0026] ▿ 2 ( ϵ kk + α I ( 1 + v ) 3 K ( 1 - ...

Embodiment 2

[0045] A method for stabilizing the borehole wall of fine managed pressure drilling, comprising the following steps;

[0046] 1. Through the analysis of the collapse and leakage of easy-to-collapse and easy-to-leakage formations, determine the appropriate bottom hole pressure;

[0047] 2. Calculate the actual drilling fluid density;

[0048] 3. Realize the regulation of the bottom hole pressure by controlling the pressure loss of the annular space.

[0049] Due to the existence of highly permeable flow channels, the rocks in formations that are prone to leakage and collapse are highly heterogeneous, and conventional rock mechanics analysis methods are inaccurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com