Mounting device for shock absorbers of motor vehicles

A technology for supporting devices and shock absorbers, which is applied in the direction of shock absorbers, shock absorber-spring combinations, shock absorbers, etc., can solve the problems of comfort deterioration, vibration decoupling deterioration, etc., and achieve improved response performance, decoupling high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

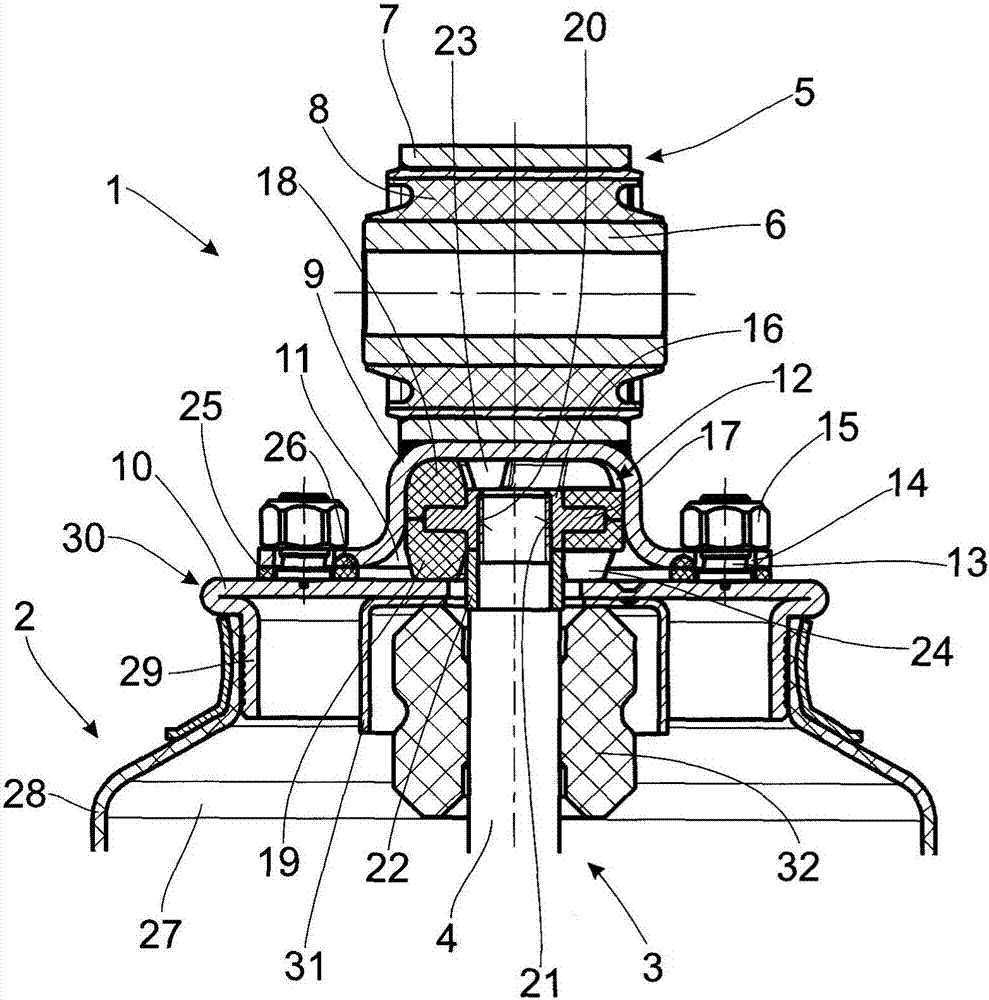

[0030] From figure 1 A sectional view of the supporting device 1 corresponding to the first embodiment of the present invention is obtained in FIG. In this case, the bearing device 1 is used in a truck in the region of the driver's cab bearing structure and engages here in the region of the driver's cab-side connecting structure of the spring bearing composed of the bearing spring 2 and the shock absorber 3 middle. In this case, the bearing device 1 supports a spring end of a bearing spring 2 and a damper piston 4 of a damper 3 on the cab of the truck.

[0031] if available at figure 1 As can be seen in , the bearing device 1 comprises an annular joint 5 with an inner bush 6 and a radially outer joint bush 7 relative thereto, wherein the bush 6 and the joint bush 7 pass through The elastomers (Elastomers) in the form of joint rubber 8 located between them are connected to each other. In this case, the joint rubber 8 is vulcanized onto the bush 6 and / or the joint bush 7 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com