Surface roughness measuring system and method based on successive two-angle method

A flatness and sequential technology, applied in the field of flatness measurement system, can solve problems such as low measurement accuracy, complex structure, and large influence of environmental variables, and achieve the effects of easy calculation and processing, low manufacturing cost, and small device volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

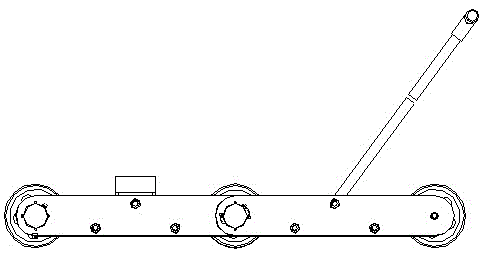

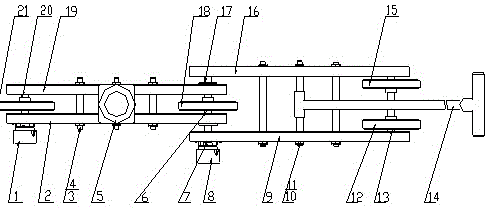

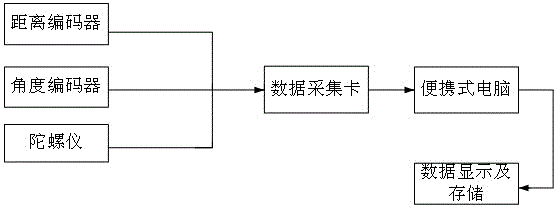

[0018] like Figure 1 to Figure 3 As shown, a road surface roughness measurement system based on the successive dichotomy method includes a data measurement system, a mechanical measurement device, and a data acquisition and display system. The data measurement system includes a distance encoder, an angle encoder, and a gyroscope; the mechanical measurement device includes a first rear link 2, a first front link 9, a second front link 16, a second rear link 19, and an intermediate shaft 6 , the first connecting rod shaft 7, the second connecting rod shaft 13, the third connecting rod shaft 17, the fourth connecting rod shaft 20, the rear wheel 21, the intermediate wheel 18, the first front wheel 12, the second front wheel 15, the tie rod 14 etc. The intermediate wheel 18 and the rear wheel 21 are respectively mounted on the intermediate shaft 6 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com