Measurement method for contribution rate of commingled production crude oil capacity

A technology for commingled production of crude oil and determination method, which is applied in measurement devices, special data processing applications, instruments, etc., can solve the problems of immaturity of commingled production, affecting the accuracy of calculation of the contribution rate of commingled oil production capacity, and multiple economic inputs.

Active Publication Date: 2014-10-15

CHINA UNIV OF PETROLEUM (EAST CHINA)

View PDF5 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The above method has the following deficiencies: first, it is necessary to set up a single-layer crude oil fingerprint library (using a single-layer test oil sample), and perform full-oil chromatographic analysis on the single-layer crude oil respectively. crude oil samples

This requires more economic investment and makes the operation more complicated; second, in a work area, for the crude oil fingerprints of the same reservoir, there may be differences in the crude oil fingerprints determined by different oil wells, and the crude oil fingerprints in the fingerprint library are It is determined by an oil well, and with the exploitation of oil and gas, the crude oil in the same oil layer due to internal differentiation will cause differences in the properties of the crude oil extracted in different periods, which will directly affect the calculation accuracy of its contribution to the combined production of crude oil; Third, it is still not mature enough to solve the problem of joint mining with more than three floors; Fourth, although some technologies have achieved good application results, they still have disadvantages such as high cost and complicated operation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

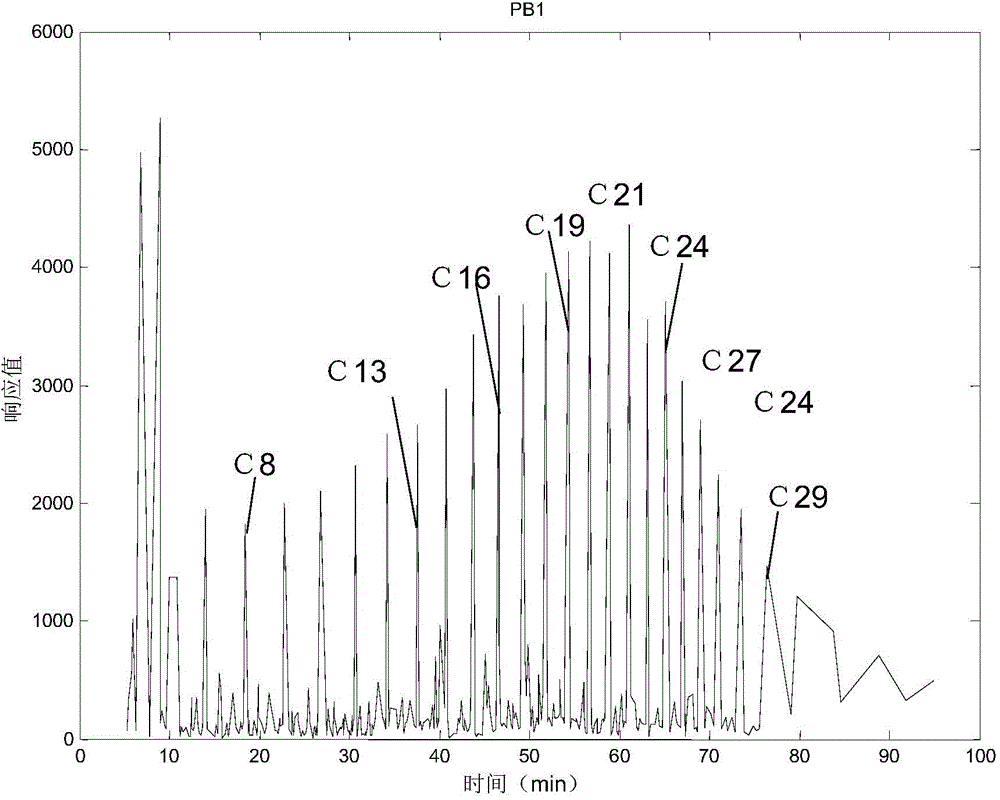

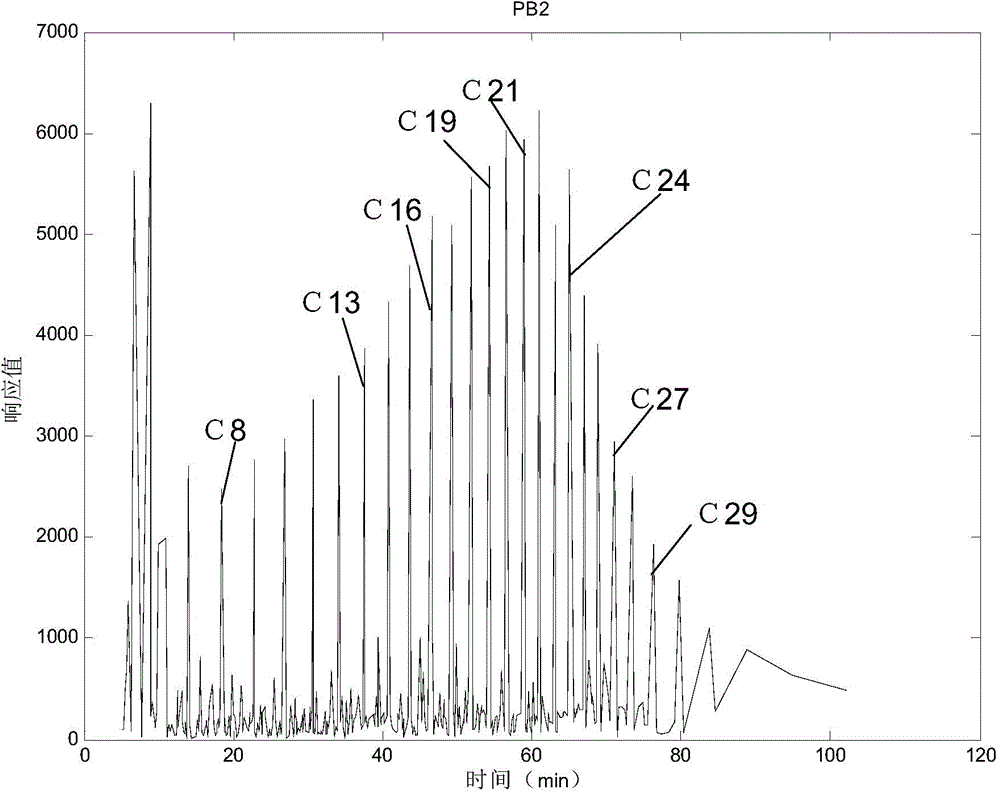

[0086] Example 1: Taking the Pubei block of Daqing Oilfield as an example, the number of oil production layers are all multi-layer commingled production, and four wells PB1, PB2, PB3 and PB4 are selected, and the commingled oil production layers of these four wells are all 3 layers.

[0087] (1) Well selection analysis

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

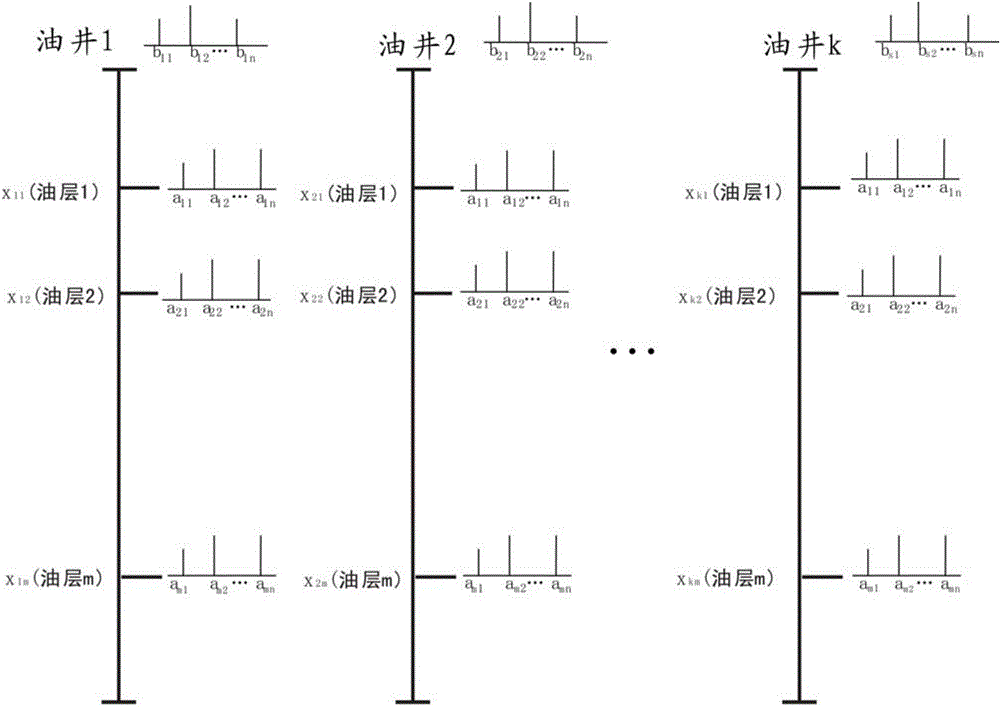

A measurement method for contribution rate of commingled production crude oil capacity utilizes the capillary gas chromatography hydrocarbon finger-print detection technology of the crude oil, performs analysis on the finger-print composition of hydrocarbon in the crude oil at the level of molecule, and reflects the composition and content of the hydrocarbon compound in the crude oil; measurable differences exist among the concentration of composition of each layer of crude oil (such as isoalkane, cyclane, and the like) in the chromatograph hydrocarbon finger-print. According to the method, the multiple inlets crude oil capillary gas chromatography hydrocarbon finger-prints are used together to deduce backwards to obtain the yield contribution ratio of crude oil of each layer, single-layered crude oil finger-print library (using single-layered test oil sample) is not required, and the method is economical and practical, and is simple and convenient to operate.

Description

technical field [0001] The invention relates to a method for measuring the production capacity contribution rate of joint production crude oil, belonging to the technical field of petroleum development. Background technique [0002] In order to save costs and maximize benefits, in the development and production of oilfields, production wells are mostly exploited in the mixed manner of several oil layers. Only by understanding the layered productivity contribution of mixed production wells can we scientifically determine which oil layer needs water injection, which oil layer needs steam injection or take other production stimulation measures, and then guide the scientific and efficient development of oil and gas fields. At present, the commonly used methods for layer productivity monitoring include production logging, layer testing, and tracer tracking. The disadvantages of these methods are high cost, long period, and are not suitable for low flow rate and channeling oil wel...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N30/86G06F19/00

Inventor 薛海涛卢双舫刘敏田善思王伟明王民李吉君陈方文黄文彪肖佃师

Owner CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com