Light guide and high uniformity and high brightness light source module

A technology of light guide components and light source modules, which is applied in the direction of optical components, semiconductor devices of light-emitting components, light sources, etc., which can solve the problems of poor light utilization, inability to effectively use LEDs, uneven light output, etc., and achieve the goal of overcoming light utilization. bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

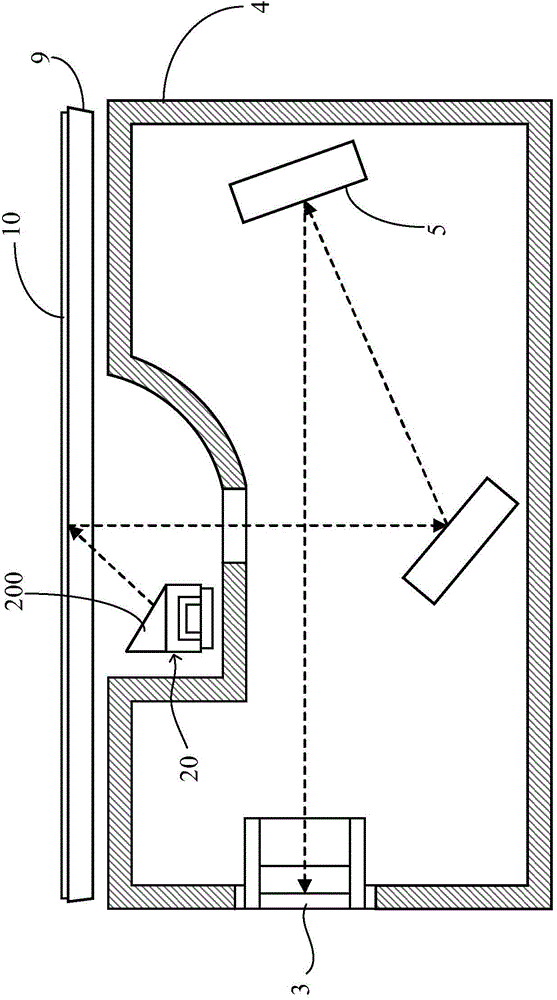

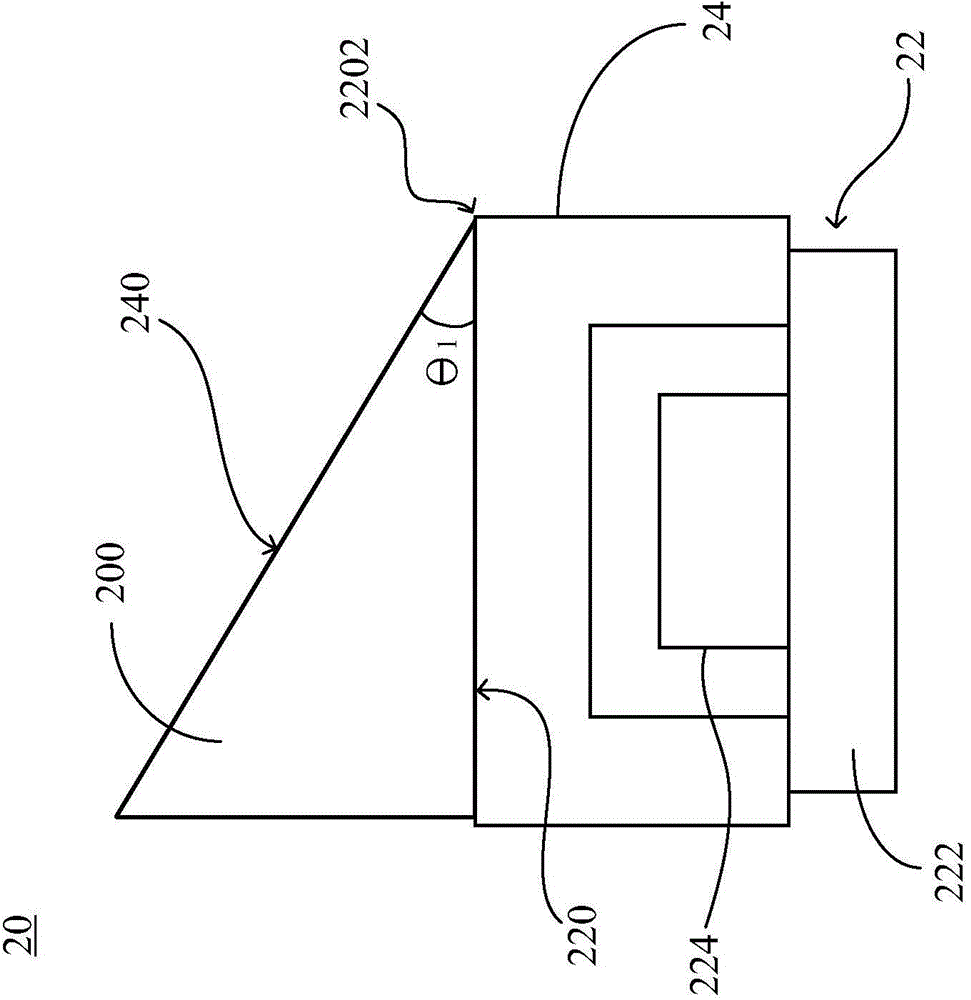

[0024] The first preferred embodiment of the light guide element of the present invention will be described in detail below with reference to the accompanying drawings, wherein the same reference numerals in different drawings represent the same or similar components. Please refer to figure 2 , figure 2 A schematic cross-sectional view of a contact image sensor according to a first preferred embodiment of the present invention is shown, wherein the light source module of this preferred embodiment is represented by symbol 20, and the light guide element of this preferred embodiment is represented by symbol 200 .

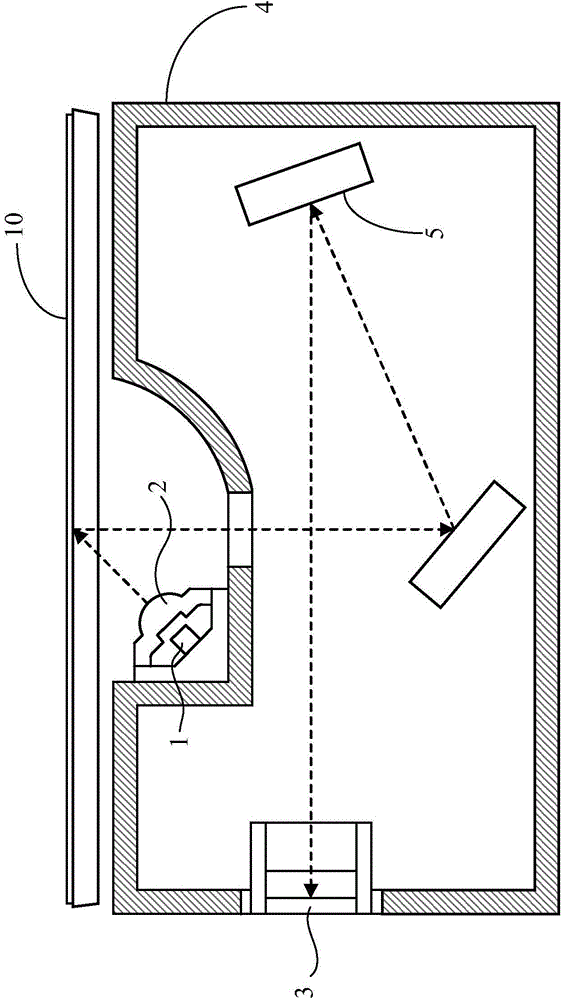

[0025] The contact image sensor includes a light source module 20 with high uniformity and high brightness, a photosensitive unit array 3 , a strip-shaped square box 4 , multiple reflectors 5 , and a light-transmitting plate 9 . When scanning the document 10, the light source module 20 irradiates light onto the document 10, and after the incident light is reflecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com