Electroluminescent device, manufacturing method of electroluminescent device and display device

一种电致发光器件、发光层的技术,应用在电致发光光源、电光源、电气元件等方向,能够解决易受水分的影响、发光亮度低、发光效率低等问题,达到解决发光不均匀、提高发光亮度、提高发光效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

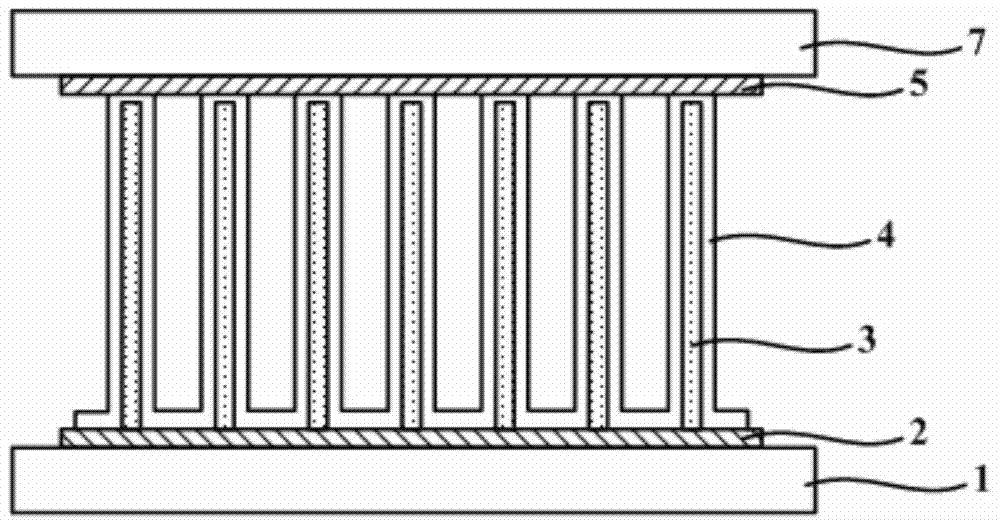

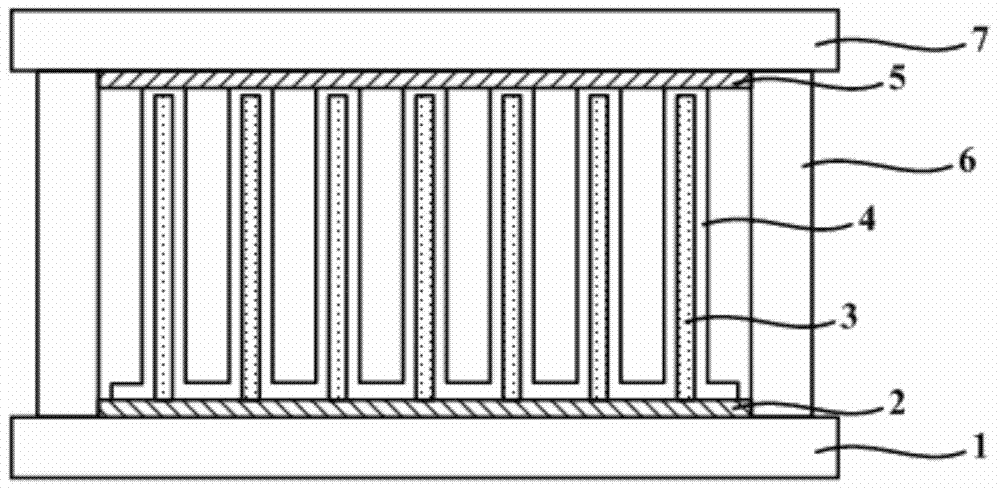

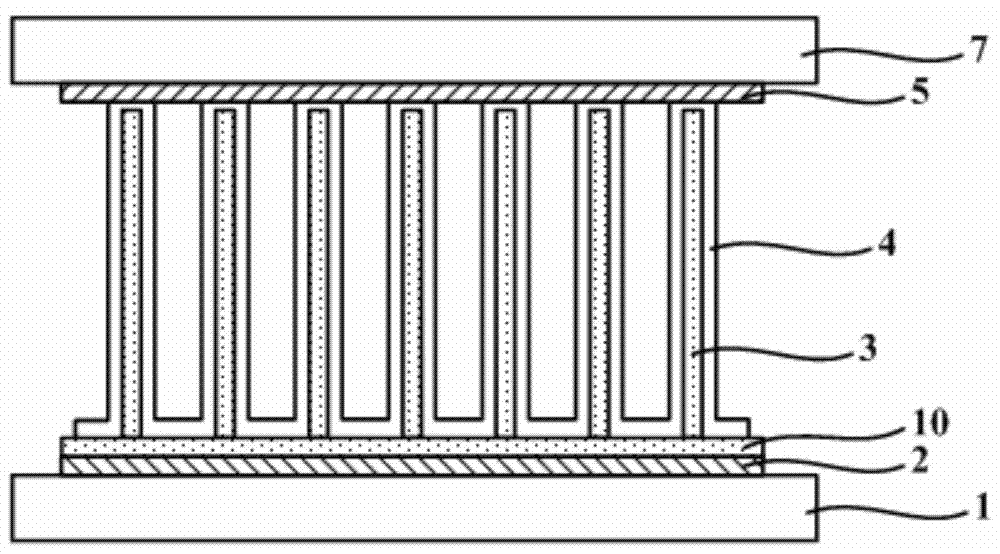

[0088] Such as Figure 5a As shown, Figure 5a In order to fabricate the structure diagram of the electroluminescent device with the alignment layer, the alignment layer 10 is fabricated on the back plate 1 where the driving circuit and the first electrode 2 have been prepared. The alignment layer 10 is made of the same material as the nanowire, and has a thickness of about 50%. ~2000 Angstroms. In this embodiment, the orientation layer 10 is a P-type film, and the first electrode 2 is a transparent conductive layer, such as indium tin oxide (ITO), indium zinc oxide (IZO), indium gallium zinc oxide (IGZO) or For other transparent conductive semiconductor films, the backplane 1 needs to be etched in advance for supporting insulating materials, such as SiO 2 ;

[0089] Such as Figure 5b As shown, Figure 5b In order to complete the structure diagram of the electroluminescent device with nanowires, in a vacuum environment, the back plate with the alignment layer 10 is heated to a ce...

Embodiment 2

[0095] Please continue to refer Figure 5a As shown, an orientation layer 10 is fabricated on the back plate 1 on which the drive circuit and the first electrode 2 have been prepared. The material of the orientation layer 10 is the same as that of the nanowires. In this embodiment, the orientation layer 10 is a P-type film. The electrode 2 is a transparent conductive layer, and the back plate 1 needs to be etched in advance for supporting insulating materials, such as SiO 2 , The thickness is about 50~2000 angstroms;

[0096] Please continue to refer Figure 5b As shown, in a vacuum environment, the backplane with the orientation layer 10 is heated to a certain temperature range, such as 150°C to 600°C, and the single crystal P-type nanowires are grown on the orientation layer 10 by the VS (Vapor Solid) method 3. The catalyst is Ga, and the source gas will self-nucleate into GaAs nanowires with a single crystal orientation and uniform morphology during the deposition process. Acco...

Embodiment 3

[0102] Please continue to refer Figure 5a As shown, the alignment layer 10 is made after the drive circuit and the first electrode 2 have been prepared. The alignment layer 10 is made of the same material as the nanowire, and has a thickness of about 50-2000 angstroms. The first electrode 2 is a reflective metal cathode, such as aluminum. (Al), molybdenum tungsten alloy (MoW), molybdenum neodymium alloy (MoNd), aluminum neodymium alloy (AlNd) or other metals or alloys that can be used as cathode materials. The back plate 1 needs to be etched in advance for supporting insulation Material, such as SiO 2 ;

[0103] Please continue to refer Figure 5b As shown, in a vacuum environment, the backplane with the orientation layer 10 is heated to a certain temperature range, such as 150°C to 600°C, and the single crystal N-type nanowire 3 is grown on the orientation layer 10 by the VLS method. The catalyst is Au, the source gas self-nucleates during the deposition process into nanowires ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com