Stackable magnetic conductive structure

A technology of magnetic conduction and magnetic conduction components, which is applied in the direction of magnetic core/yoke, transformer/inductor core, electrical components, etc., which can solve the problems of coil resistance drop, serious skin effect, and poor enameled wire occupation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

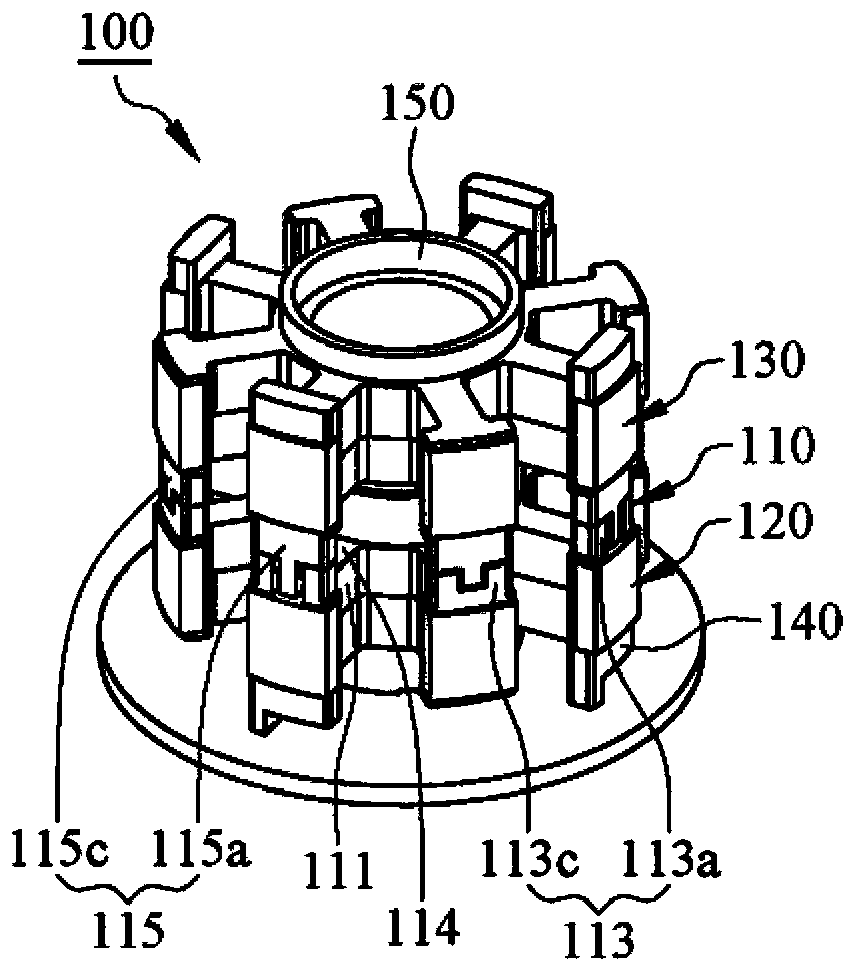

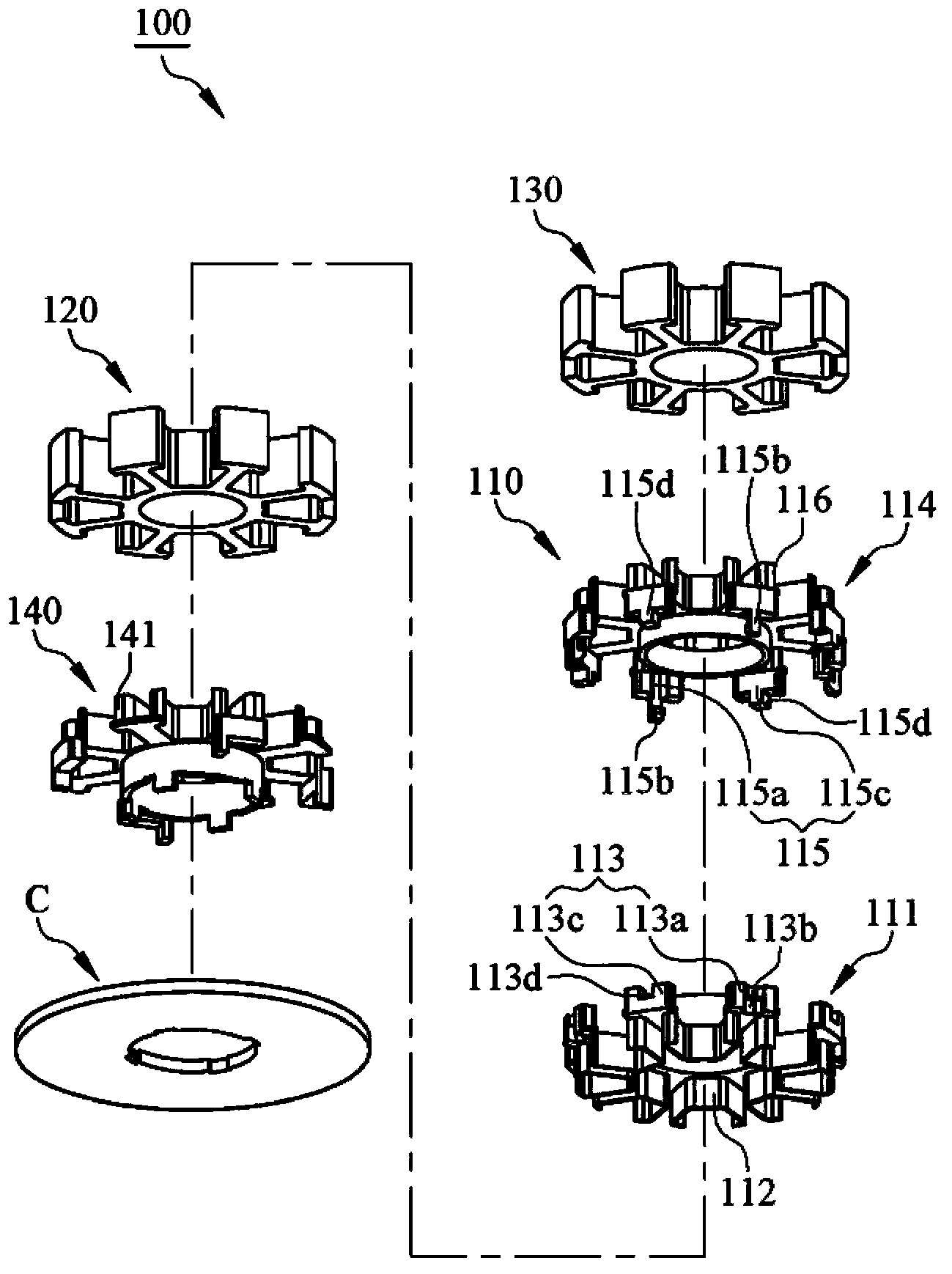

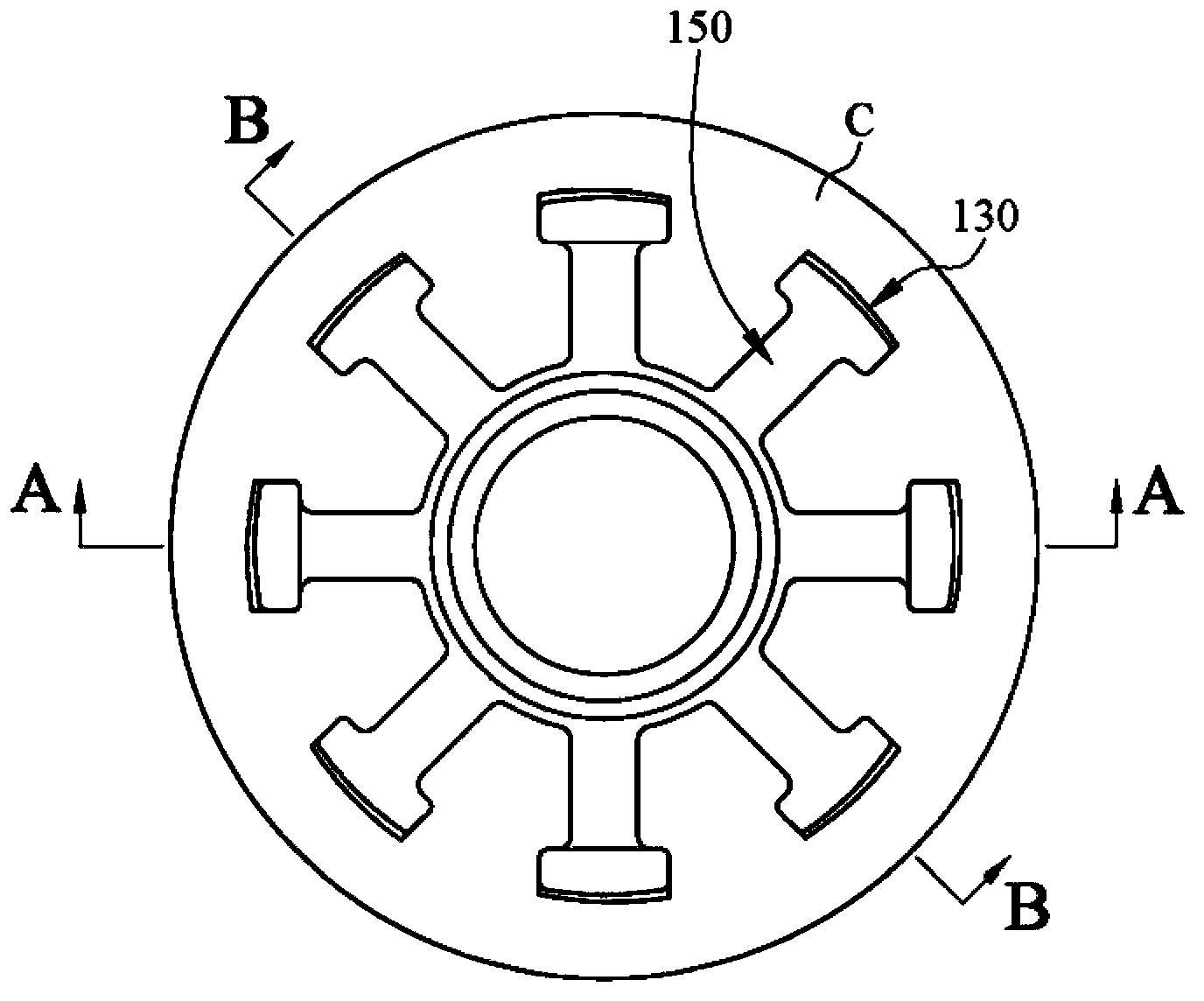

[0046] see figure 1 and figure 2 , which is the first embodiment of the present invention, a stackable magnetic permeable structure 100, which includes a first insulating frame group 110, a first magnetic permeable element 120 and a second magnetic permeable element 130, the first insulating frame group 110 includes a first insulating frame 111 and a second insulating frame 114, the first insulating frame 111 and the second insulating frame 114 are stacked on each other, in this embodiment, the second insulating frame 114 is stacked on the first insulating frame 111 above.

[0047] see figure 1 and figure 2, the first insulating frame 111 has a first joint portion 112 and a first spacer portion 113, the first spacer portion 113 is formed above the first joint portion 112, and the second insulating frame 114 has a second spacer portion 115 and a first spacer portion 113 Two joint parts 116, the second spacer 115 is formed below the second joint part 116, the second insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com