Pole-attached coil of DC motor and its winding method

A DC motor and motor winding technology, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of easy damage to the insulation of inter-turn intersections, short circuits between turns, and low winding density of turns, so as to facilitate wiring and The effect of installation operation, improving power density, and increasing the number of winding turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

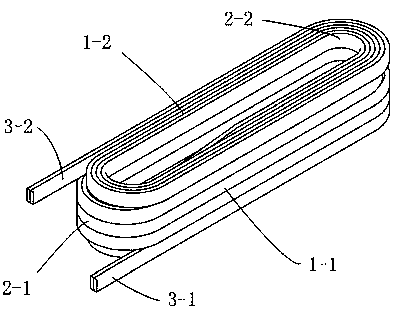

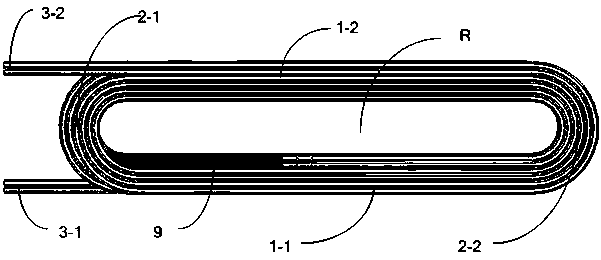

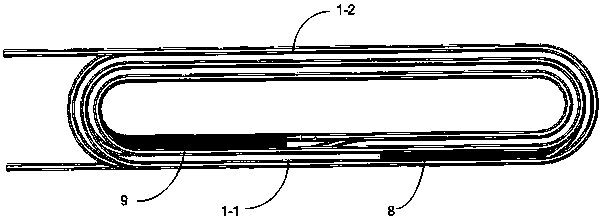

[0058] see Figure 1 to Figure 9 As shown, this embodiment provides a polarized coil of a DC motor, comprising: an elliptical ring body formed by winding one or more parallel motor winding wires; wire 3-1, and the second lead-out wire 3-2 arranged at the end of the motor winding wire. In this embodiment, the structure of two parallel motor winding wires is taken as an example.

[0059] Specifically, the elliptical ring body includes a forward winding coil group and a reverse winding coil group formed by integral winding; the forward winding coil group and the reverse winding coil group are wound to form a relatively distributed first straight line portion 1- 1 and the second straight part 1-2, and the first arc part 2-1 and the second arc part 2 which are connected to the first straight part 1-1 and the second straight part 1-2 and are relatively distributed -2; the first lead-out line 3-1 is located at the outer end of the elliptical inner hole R of the forward winding coil...

Embodiment approach

[0061] The motor winding wire of this embodiment is preferably a winding wire with its own insulating layer; in an optional embodiment, the winding wire is a double glass fiber-wrapped film-wrapped copper flat wire or a single glass fiber-wrapped film-wrapped copper flat wire. There is no absolute limit to the specific model of the specific double glass fiber wrapped film wrapped copper flat wire or single glass fiber wrapped film wrapped copper flat wire.

[0062] With reference to the drawings of the embodiment, this embodiment takes a pole-attached coil with a three-layer structure as an example, the number of layers of the forward winding coil group is three layers, and the number of layers of the reverse winding coil group is three layers. The first lead-out line 3-1 protrudes from the first straight line 1-1 to the direction in which the first arc-shaped portion 2-1 extends; the second lead-out line 3-2 extends from the second straight line 1-2 to the first arc The direc...

Embodiment 2

[0070] This embodiment provides a method for winding an attached pole coil of a DC motor, which specifically includes:

[0071] Step S1: Reserve a section of motor winding wire at one end of one or more parallel motor winding wires to form the reserved motor winding wire 11; the length of the reserved motor winding wire is equal to or greater than that of the reverse winding coil group The sum of the length of the required motor winding wire and the length of the first lead wire 3-1;

[0072] Step S2: Three layers of motor winding wires other than the reserved motor winding wires in the motor winding wires in step S1 are forward wound to form a forward winding coil group; at the end of the motor winding wire of the forward winding coil group, The second lead-out line 3-2;

[0073] Step S3: Reversely wind three layers of the reserved motor winding wire 11 in step S1 to form a reverse winding group; the reverse winding direction of the reverse winding group is the same as that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com