Glass roving package

A glass fiber yarn and package technology, which is applied in the field of glass fiber yarn packages, can solve problems such as the need for labor, the time spent on glass fiber yarn, and the misalignment of glass fiber yarn packages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below, based on Figure 1 to Figure 6 Embodiments related to the glass fiber yarn package of the present invention will be described. However, the present invention is not intended to be limited to the embodiments described below and the structures described in the drawings.

[0051] 【Glass fiber yarn packing body】

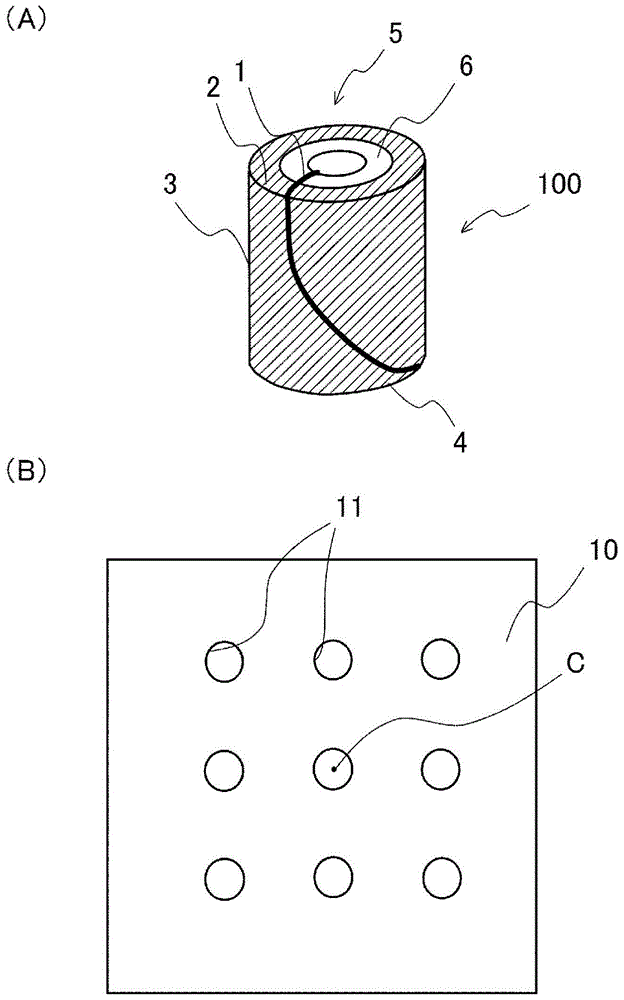

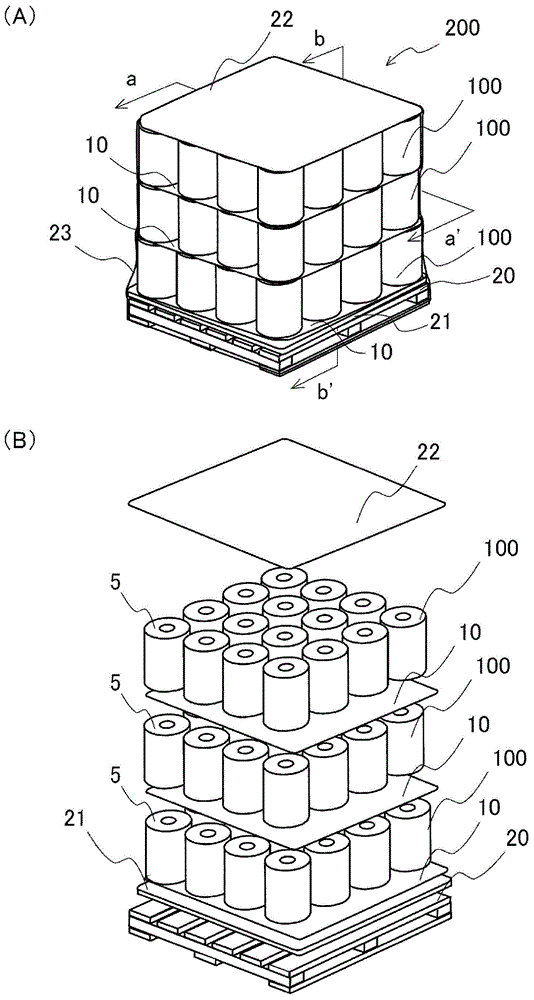

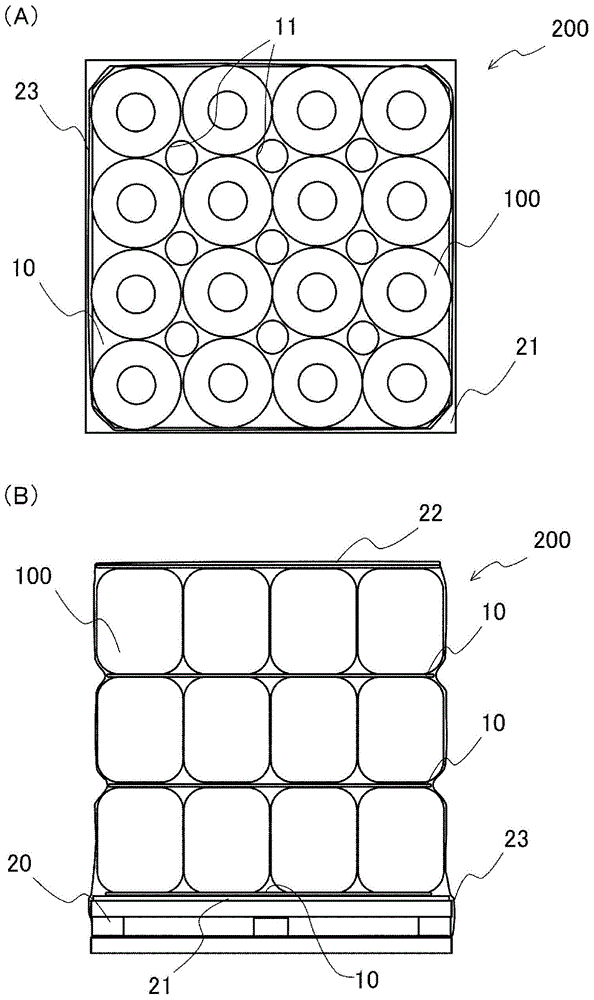

[0052] figure 1 The glass fiber yarn 100 and the positional displacement prevention sheet 10 used in this invention are shown, (A) is a perspective view of the glass fiber yarn 100, (B) is the top view of the positional displacement prevention sheet 10. Such as figure 1 As shown in (A), the glass fiber yarn 100 is, for example, a bundled yarn formed by bundling several hundred glass fiber monofilaments such as E glass or AR glass with a fiber diameter of several μm to several tens of μm in a predetermined order. The bundled glass yarn 1 is formed by doubling, and the bundled glass yarn 1 is wound into a cylindrical shape and shrink-wrapped with an olefi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com