Device and method for chemical fiber rope heat-treatment

A rope and chemical fiber technology, applied in the field of chemical fiber rope heat treatment equipment, can solve the problems of inconvenient production and use, uneven balance tension, rough appearance, etc., and achieve the effect of increasing strength, increasing elongation at break, and stable and reliable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

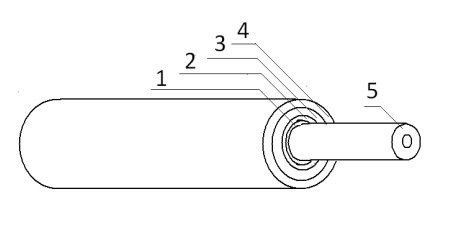

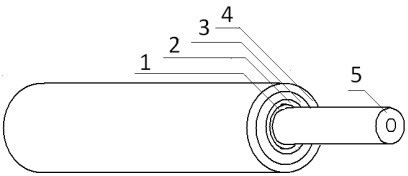

Image

Examples

Embodiment 1

[0018] Embodiment 1: Carry out heat treatment to the water skiing rope. The water skiing rope in this implementation case is made of high-strength PP / high-strength synthetic fiber. The water skiing rope made of the above material is heat treated by electromagnetic heating. The tubular heater is installed between the rope production device and the rope collection device. During the heat treatment, the temperature of the heat treatment was controlled at 60°C, and the speed of the rope passing through the inner cavity of the tubular heater was controlled at 0.7m / s. Through the above heat treatment, the tension added to the rope during chemical fiber spinning, rope production and processing can be effectively overcome, resulting in tension differences between fibers and strands, so that the performance of chemical fibers cannot be maximized. At the same time, this method can also effectively and quickly eliminate the phenomenon of uneven tension inside the rope, so that the rope h...

Embodiment 2

[0019] Embodiment 2: Carry out heat treatment to climbing rope. The material of the mountaineering rope in this implementation case is nylon, and the above-mentioned material is made of the mountaineering rope with a production process of 48 spools, and the heat treatment is carried out by means of electromagnetic heating. The tubular heater is installed in the rope production device and the rope collection device Between, the temperature of the heat treatment is controlled at 130°C, and the speed of the rope passing through the inner cavity of the tubular heater is controlled at 0.55m / s. Through the above heat treatment, the tension added to the rope during chemical fiber spinning, rope production and processing can be effectively overcome, resulting in tension differences between fibers and strands, so that the performance of chemical fibers cannot be maximized. At the same time, this method can also effectively and quickly eliminate the phenomenon of uneven tension inside t...

Embodiment 3

[0020] Embodiment 3: Carry out heat treatment to the traction rope. The material of the traction rope in this implementation case is high-strength PE monofilament. The traction rope made of the above material is heat-treated by electromagnetic heating. The tubular heater is installed between the rope production device and the rope collection device. The temperature is controlled at 70°C, and the speed of the rope passing through the inner cavity of the tubular heater is controlled at 1.0m / s. Through the above heat treatment, the tension added to the rope during chemical fiber spinning, rope production and processing can be effectively overcome, resulting in tension differences between fibers and strands, so that the performance of chemical fibers cannot be maximized. At the same time, this method can also effectively and quickly eliminate the phenomenon of uneven tension inside the rope, so that the rope has a better appearance and feel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com