Glass cutter cleaning apparatus

A cleaning device, glass cutting technology, applied in glass cutting devices, glass manufacturing equipment, cleaning methods and utensils, etc., can solve the problems of short service life of cutting knives, glass fragments splashing, gaps, etc., to prevent splashing into people , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

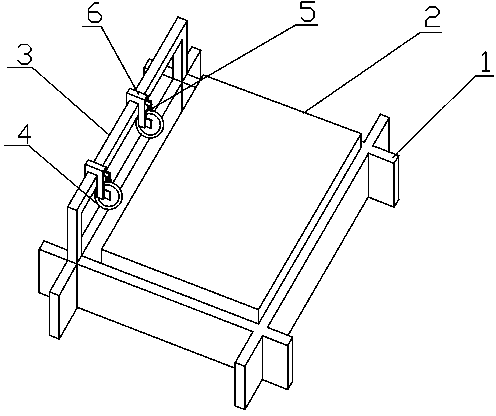

[0008] Such as figure 1 As shown, a glass cutting knife cleaning device is composed of a fixed frame 1, a workbench 2, a cross bar 3, a cutting knife 4, a water spray head 5 and a sliding rod 6, and the workbench 2 is horizontally fixed on the On the fixed frame 1, the slide bar 6 is installed on the cross bar 3, the cutting knife 4 is installed at the lower end of the slide bar 6, and the sprinkler head 5 is suspended above the cutting knife 4, And be connected with described slide rod 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com