Device for turning on and turning off charging bell

A material clock and conveyor belt technology, which is used in the field of closing and opening devices, can solve problems such as affecting the material clock, poor lubrication effect, and transmission of unfavorable movements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

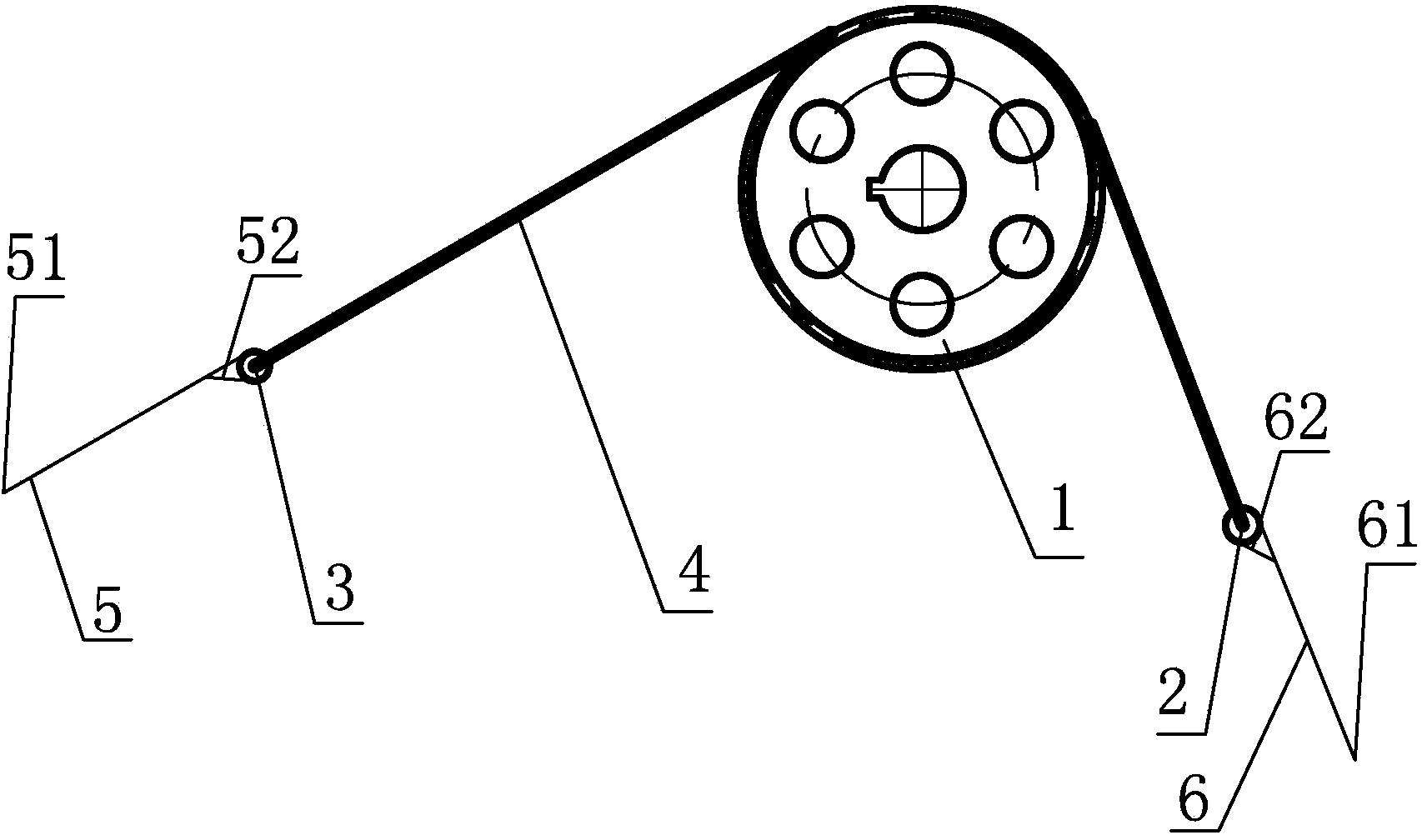

[0016] Such as figure 1 As shown, the device for opening and closing the material bell of the present invention includes a driven wheel 3 connected to the pull rod on the material bell through a conveyor belt, a driving wheel 2 connected with a winch through a conveyor belt, and a driving wheel between the driven wheel 3 and the driving wheel 2. The guide wheel 1, the driven wheel 3 and the driving wheel 2 are all small rope wheels, the guide wheel 1 is located at the top, the guide wheel 1 is a sprocket, the guide wheel 1 is wound with a chain 4, and one end of the chain 4 passes through the first pin shaft and The center of rotation of the driven wheel 3 is connected, and the other end of the chain 4 is connected with the center of rotation of the driving wheel 2 through the second pin shaft.

[0017] The conveyor belt includes a first conveyor belt 5 and a second conveyor belt 6, the first conveyor belt 5 and the second conveyor belt 6 are steel wire ropes, the first convey...

Embodiment 2

[0020] The difference between embodiment 2 and embodiment 1 is that one end of the chain 4 is welded to the center of rotation of the driven wheel 3 , and the other end of the chain 4 is welded to the center of rotation of the driving wheel 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com