Aluminium alloy substrate used for magnetic disc, and method of manufacturing the same

A technology of an aluminum alloy substrate and a manufacturing method, which is applied to the magnetic recording layer, the base layer of the recording layer, etc., can solve the problems of increasing the number of rolling passes, difficulty in preventing surface defects, and poor industrial production efficiency, and achieve excellent impact resistance. , Excellent thermal stability of flatness, excellent flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the mode for implementing the aluminum alloy substrate for a magnetic disk of the present invention and its manufacturing method will be described in detail.

[0036] [Aluminum alloy substrate for magnetic disk]

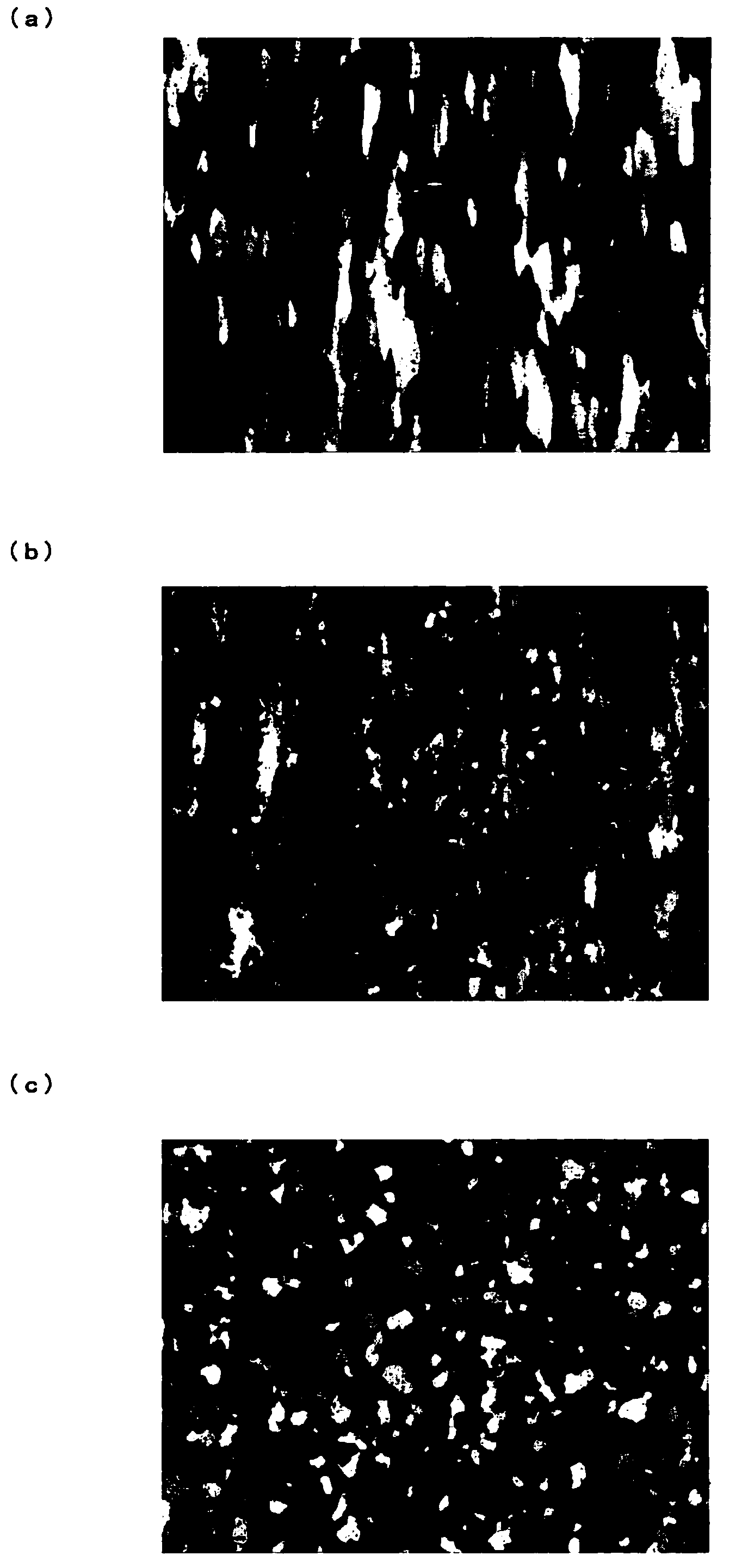

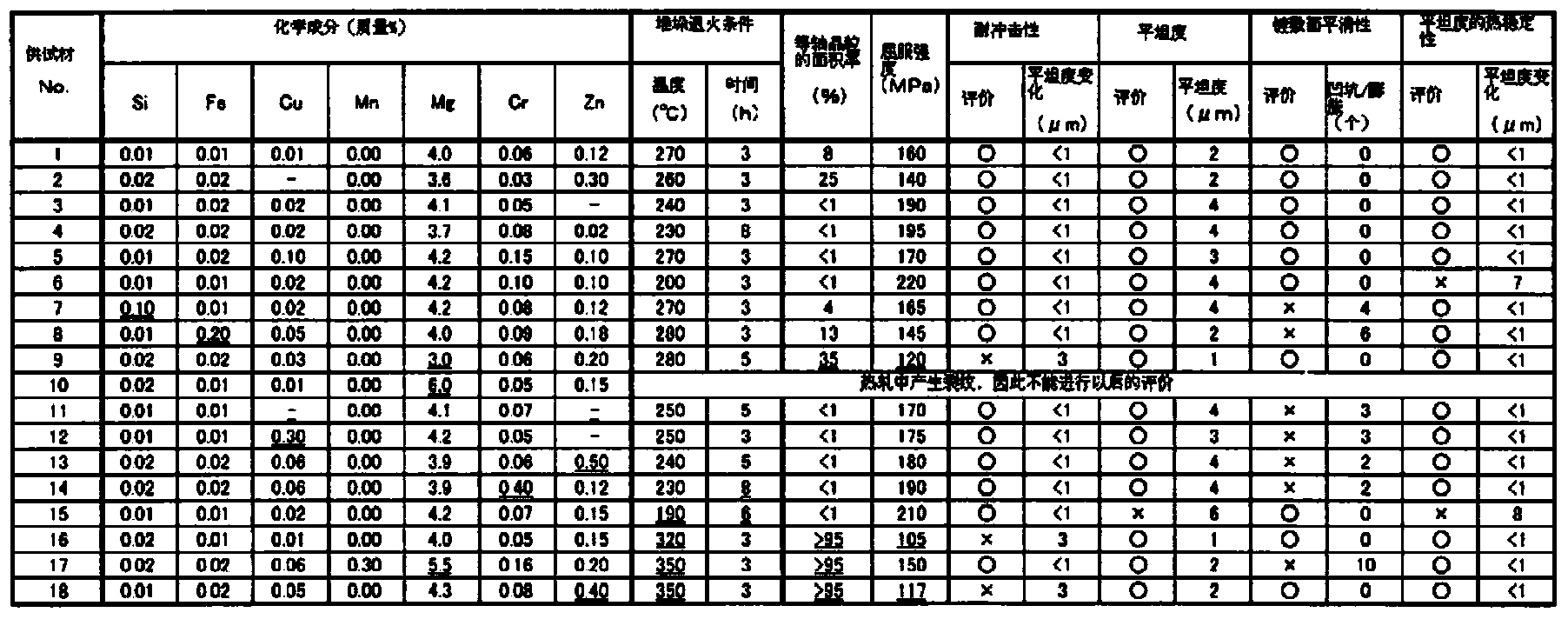

[0037] The aluminum alloy substrate for magnetic disks of the present invention (hereinafter referred to as an aluminum alloy substrate or substrate as appropriate) is characterized by being composed of an aluminum alloy containing a predetermined amount of Si, Fe, Mg, Cr, and a predetermined amount of Cu At least one of and Zn, the balance is composed of Al and unavoidable impurities, the flatness is not more than a predetermined value, and the area ratio of equiaxed grains on the substrate surface is not more than a predetermined value.

[0038] In addition, the aluminum alloy substrate for a magnetic disk of the present invention preferably has a yield strength of a predetermined value or more, and it is also preferable that the amount of change in fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com