Self-elevating ocean platform hydraulic plug lifting system

A lifting system and offshore platform technology, applied in the field of marine engineering equipment, can solve the problem of high welding seam requirements and achieve the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

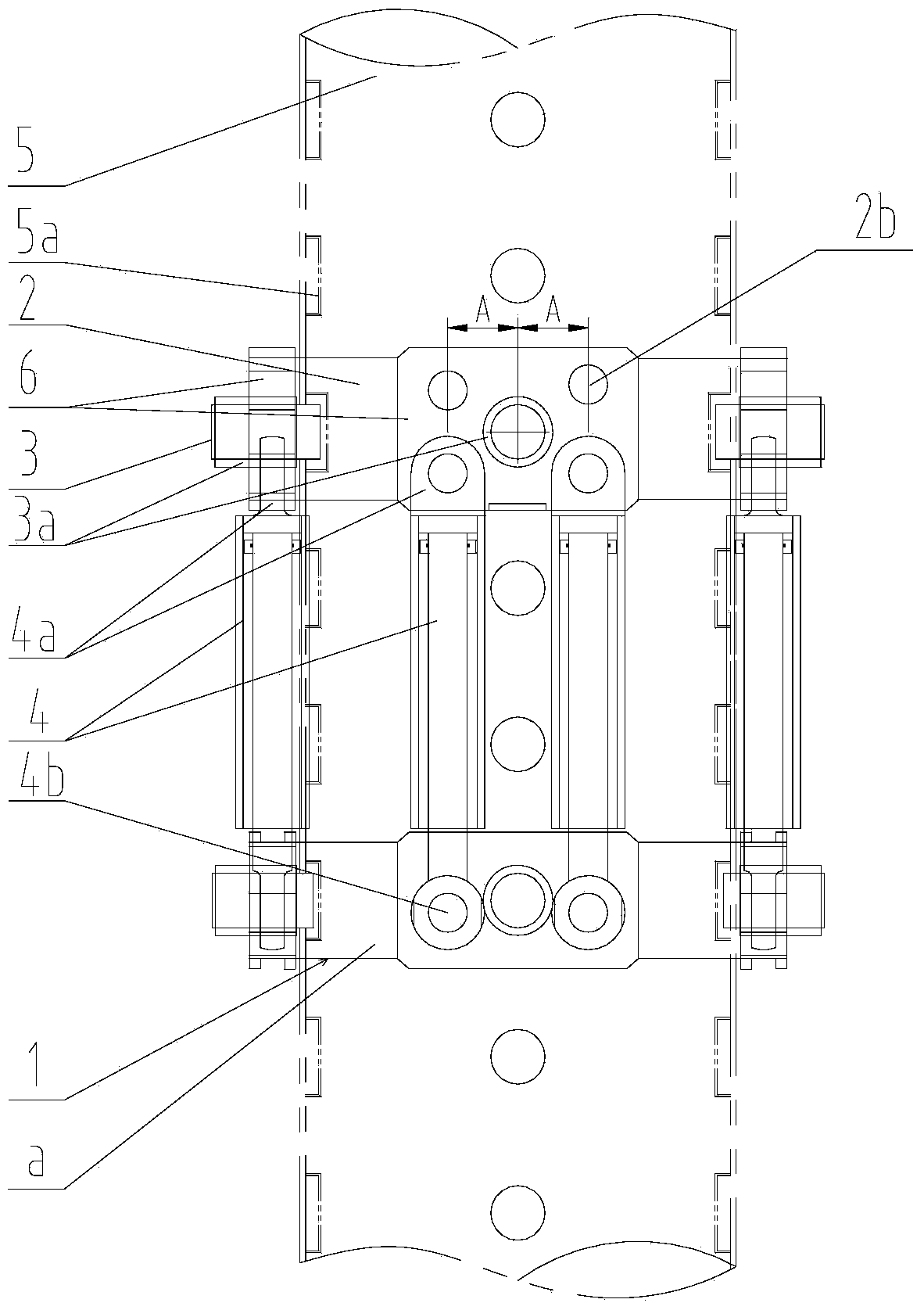

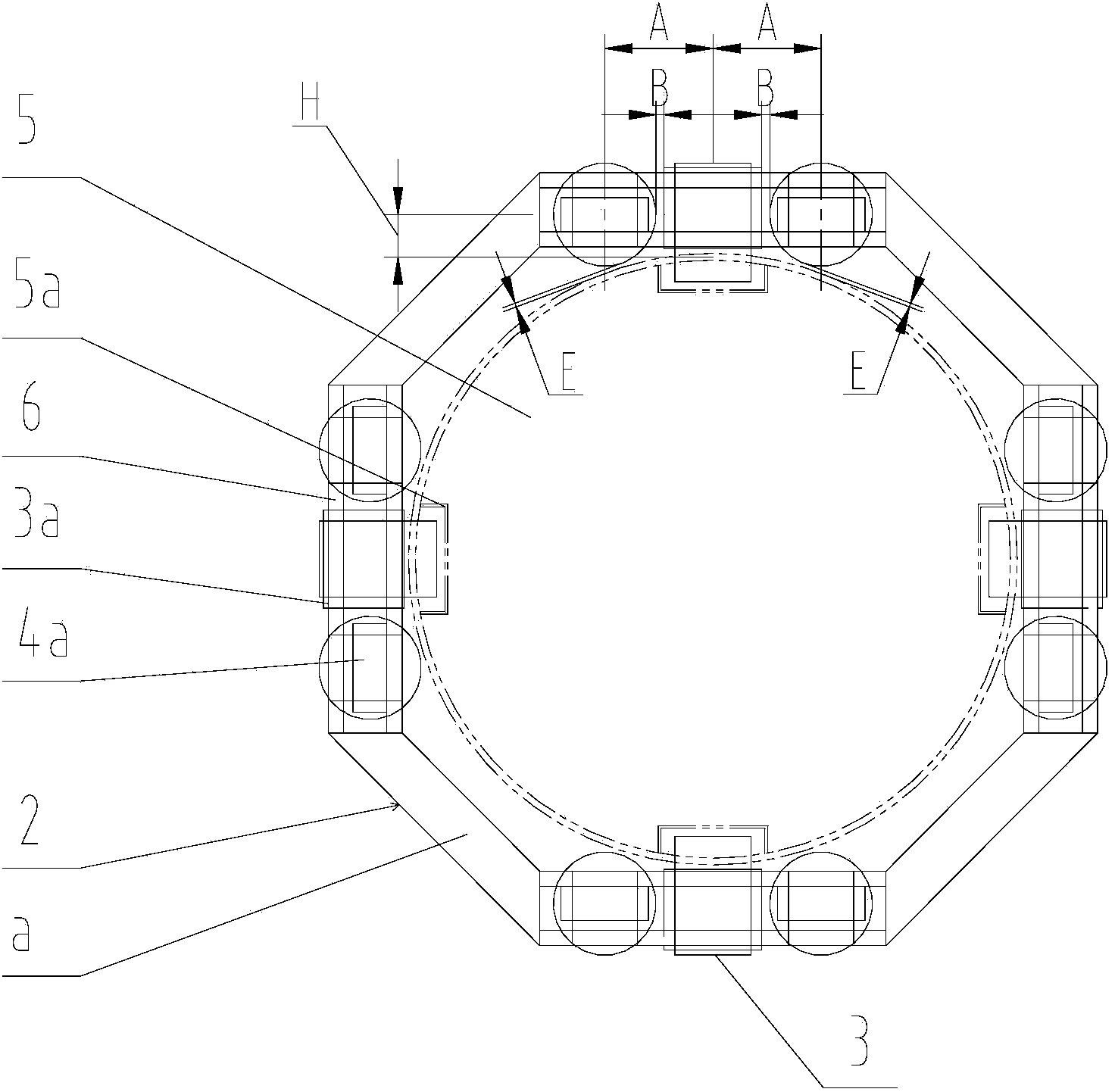

[0022] The embodiment of the present invention provides a self-elevating offshore platform hydraulic bolt lifting system, such as figure 1 and figure 2 As shown, the hydraulic bolt lifting system includes: a moving ring beam 1, a fixed ring beam 2 arranged corresponding to the moving ring beam 1, a bolt 3, and a lifting cylinder 4 installed between the fixed ring beam 2 and the moving ring beam 1, and the fixed ring beam 2 and the moving ring beam 1. The ring beam 2 and the moving ring beam 1 respectively include several crossbeams a connecting end to end. The moving ring beam 1 and the fixed ring beam 2 are equipped with bolt seats 3a, and the bolts 3 are installed in the bolt seats 3a. A lift cylinder pin seat 4a, the pin seat 3a is arranged between the two lift cylinder pin seats 4a on the beam a respectively, and one end of the lift cylinder 4 is installed on the fixed ring beam 2 through the lift cylinder pin 4b. In the oil cylinder pin seat 4a, the other end of the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com