Linear compressor

A linear compressor and compressor technology, applied in the direction of mechanical equipment, machine/engine, liquid variable capacity machinery, etc., can solve the problems of unreliable structure, poor oil supply effect, etc., and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

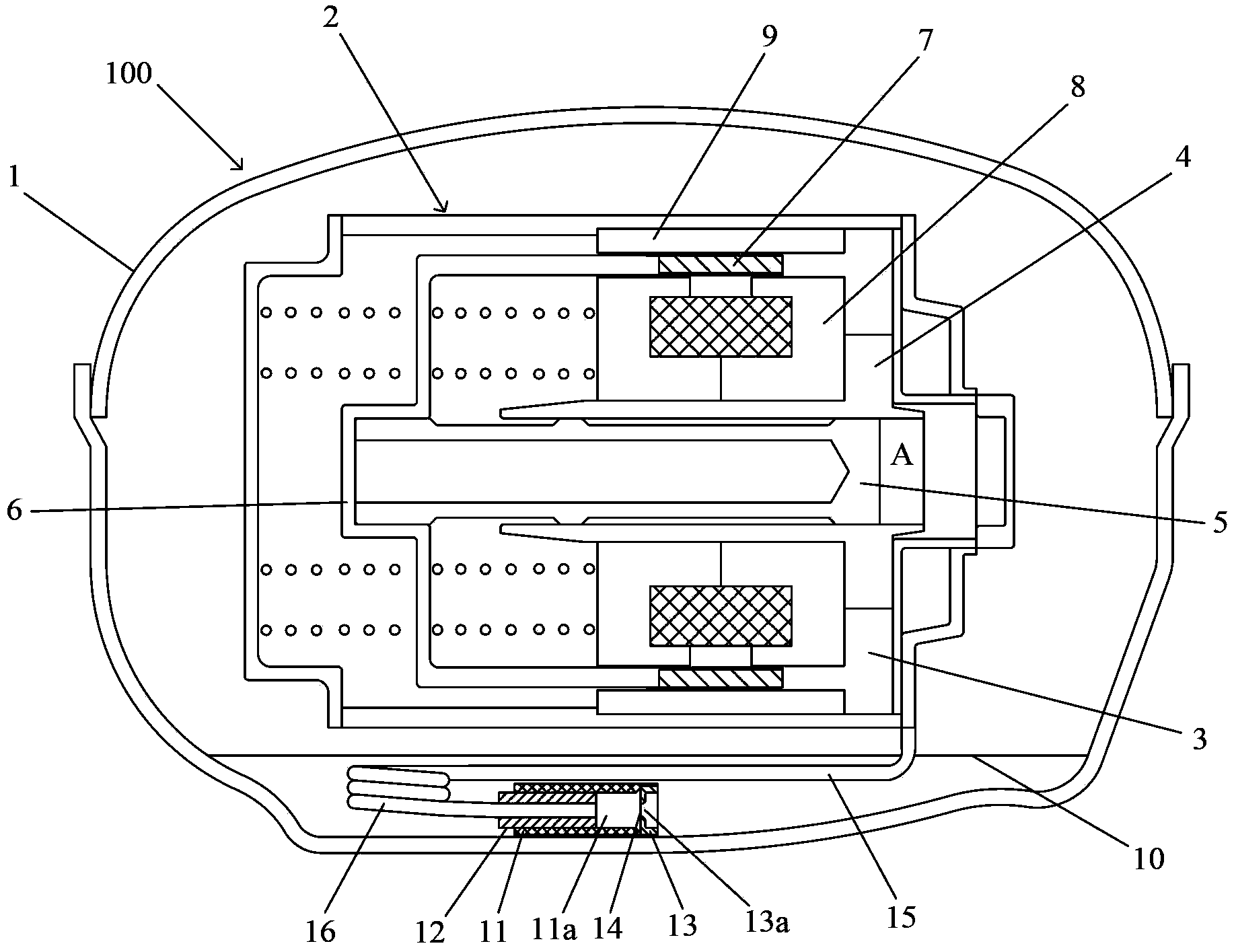

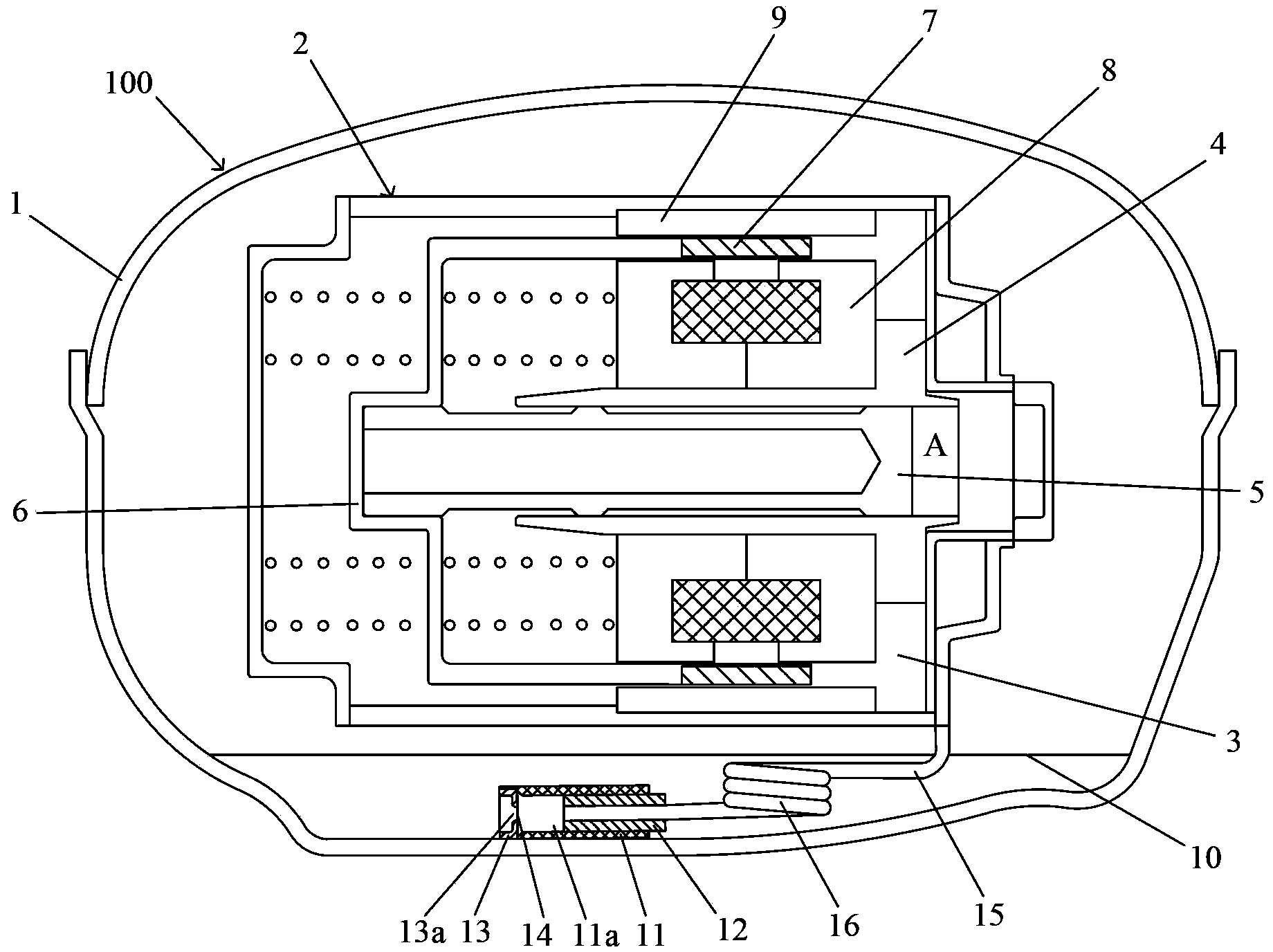

[0020] Refer to the attached figure 1 with 2 Specific implementations of the linear compressor of the present invention will be described in detail. In the following description, the front / back correspond to figure 1 Right / Left in .

[0021] Such as figure 1 As shown, the linear compressor 100 has a casing 1, and a compressor body 2 is supported in the casing 1. The compressor body 2 has a cylinder 4 supported by a support flange 3, and the cylinder 4 is horizontally arranged (its axis is in the horizontal direction, which is figure 1 Left and right direction shown), the cylinder 4 is provided with a piston 5. A valve plate is arranged at the front end of the cylinder 4, and the compression chamber A of the linear compressor is jointly surrounded by the valve plate, the end of the piston 5 and the cylinder 4. A mover frame 6 is connected with the piston 5 , and the mover frame 6 is a barrel member with an opening facing forward, and a cylindrical permanent magnet 7 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com