High-efficiency air filter scanning leak-detection device and method

A filter and leak detection technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of reducing the efficiency of scanning leak detection, easy air leakage, and affecting detection results, so as to simplify the realization of the control system and improve Effective transmission distance, convenient control system to achieve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

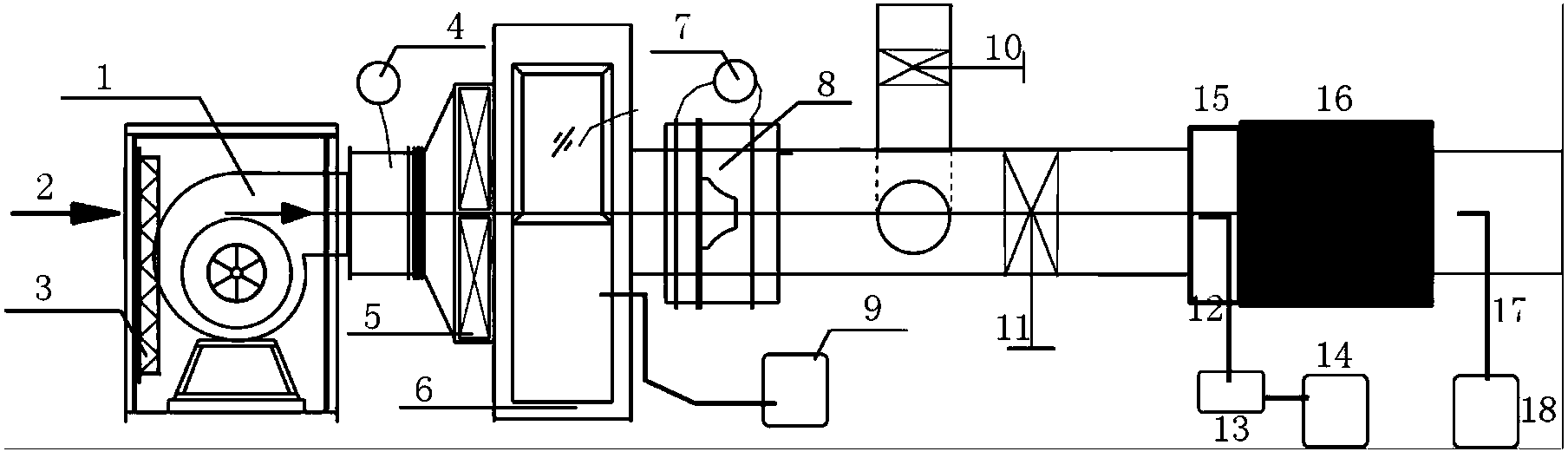

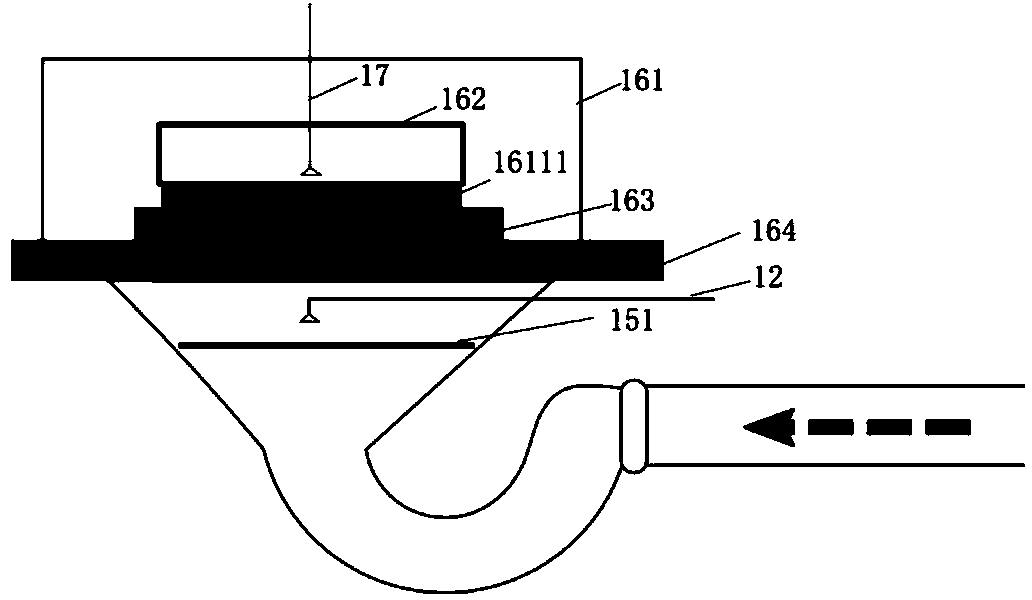

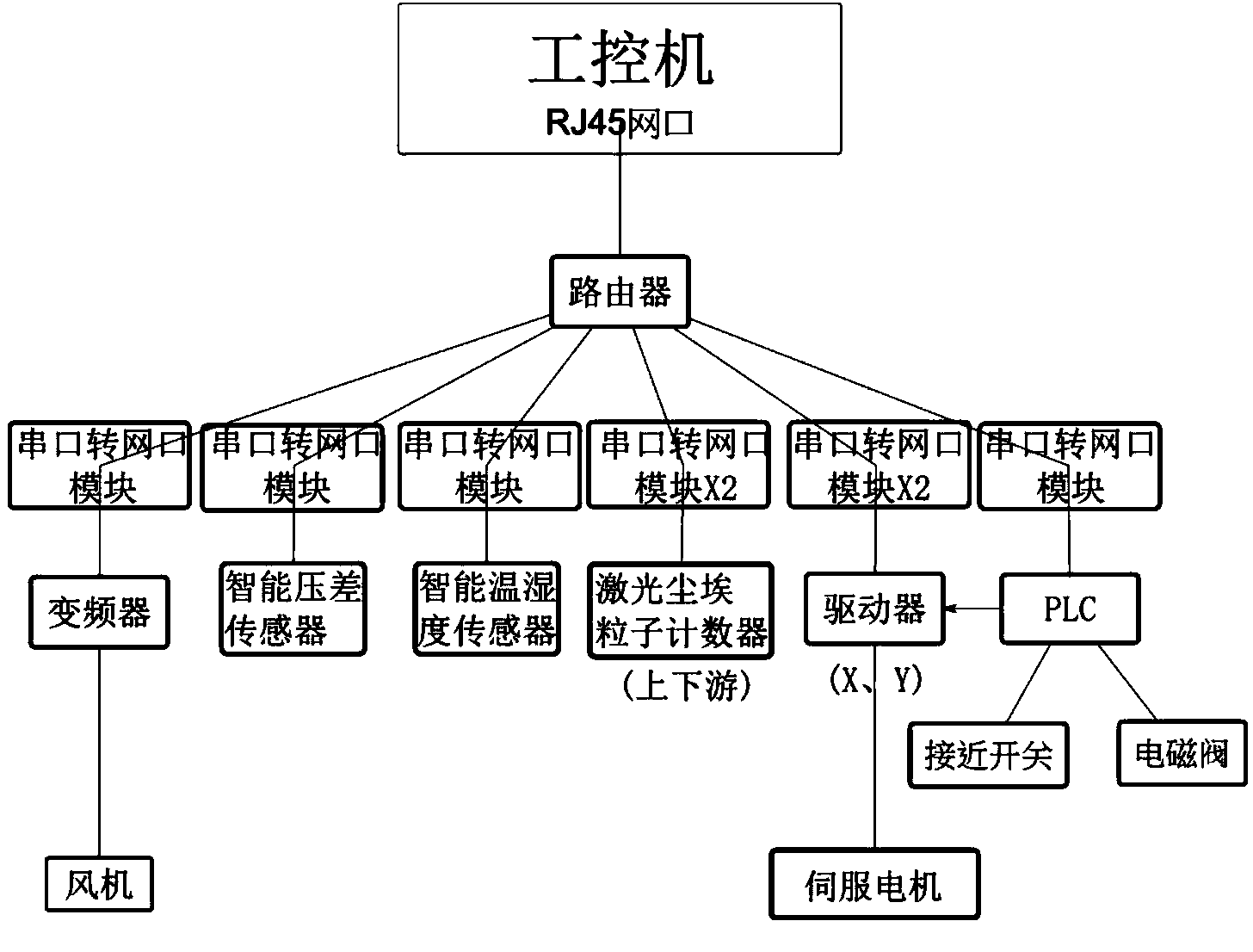

[0037] figure 1 It is a general drawing of the embodiment of the leak detection device of the present invention (the main figure is a front view, and the detection platform 16 is a general term for the components related to scanning leak detection, as can be seen from the figure, the scanning leak detection device of the high-efficiency air filter of the present invention includes an air duct system , air flow conversion device 15, detection platform 16, two-dimensional scanning mechanism 161, detection system and control system, the air duct system, air flow conversion device and detection platform are connected together in sequence; Efficiency filter 3, blower fan 1, high efficiency filter 5, mixing chamber 6, nozzle device 8, main flow valve 11 and bypass valve 10, the output end of aerosol generator 9 is connected to the input end of descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com