Defect characteristic extraction and identification method of AOI system used for bullet apparent defect detection

A technology for defect detection and identification methods, used in character and pattern recognition, optical testing flaws/defects, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The defect feature extraction and recognition method of the AOI system for the detection of apparent defects of bullets includes the following steps:

[0036] (1) Obtain the surface image of the bullet through the AOI system, and then obtain the connected domain mark image;

[0037] (2) Preset the known defect types to be inspected according to the expectations of the bullet apparent defect detection, and obtain the image characteristics required to determine each defect;

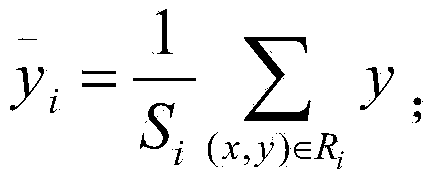

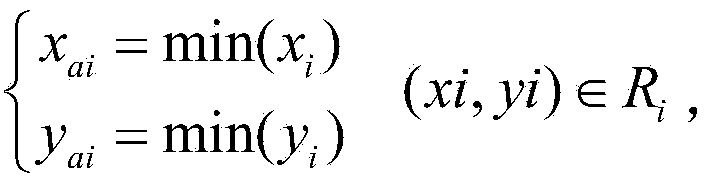

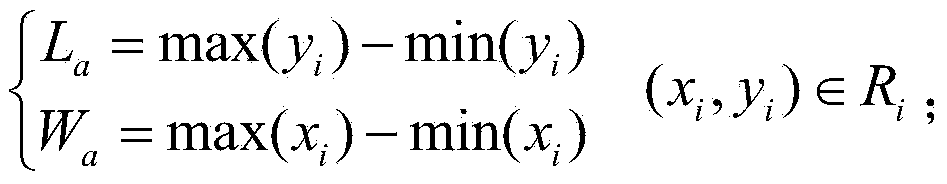

[0038] (3) Associate all required image features with the parameters of the connected domain labeled image, convert them into corresponding general formulas, and preset standard thresholds for image features;

[0039] (4) Perform image feature calculation for each connected domain on the connected domain label image, compare the result with a standard threshold, and determine the type of defect.

[0040] Wherein, in the step (1), a region growing method or a labeling algorithm is adopted to obtain the connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com