Special disassembly tool for withdrawing bolt

A technology of special tools and bolts, applied in the field of assembly and disassembly tools in machining, to achieve the effect of convenient use and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Further description is given below in conjunction with the reference signs:

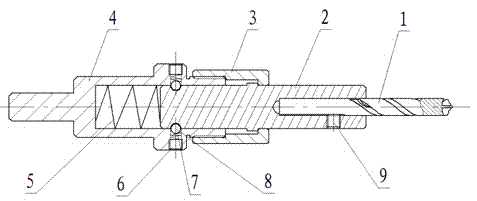

[0029] figure 1 It is a schematic diagram of the overall structure of the present invention

[0030] The special tools include: a screw drill 1, a rotating rod 2, a connecting nut 3, a clamping handle 4, a compression spring 5, a pressure regulating nut 6, a pressure regulating spring 7, a stop steel ball 8 and a locking nut 9. Thread-removing drill 1 is the main part of this set of special tools for bolt-removing. The thread-removing drill is different from ordinary drills. Its cutting edge has three parts, which respectively play the role of drilling centering, hooking bolts and increasing the rotational torque. role. When disassembling the bolts that are broken in the workpiece due to excessive pre-tightening force, apply positive pressure on the bolts through the thread unwinding drill 1 to generate sufficient dismounting torque. Its other end is fixed on the rotary connecting rod 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com