Opening and conveying mechanism for waste clothes

A technology of conveying mechanism and clothing, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problem that waste clothing cannot be recycled, and achieve the effect of light weight, simple structure and low vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

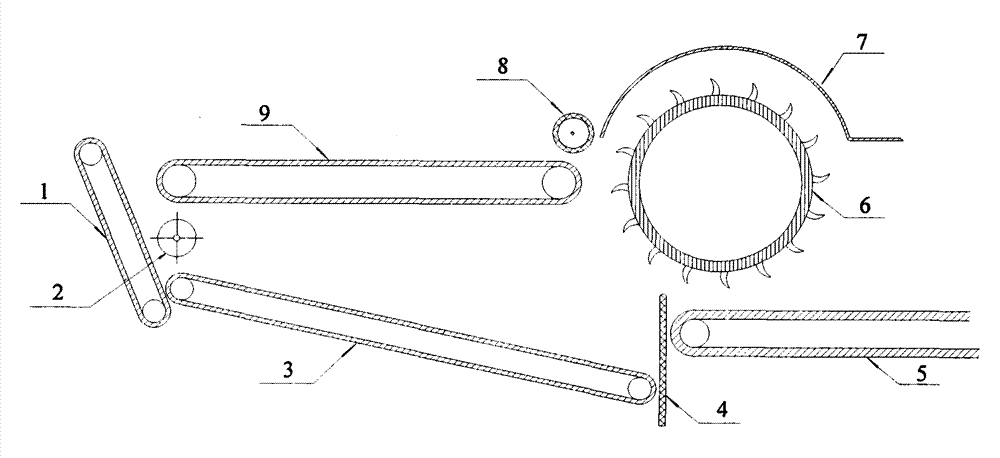

[0008] The conveying mechanism for loosening waste clothes is mainly composed of a lifting conveyor belt 1, a push roller 2, a return conveyor belt 3, a partition plate 4, a product fiber conveyor belt 5, an opening sawtooth roller 6, a top cover 7, a holding roller 8 and Feeding conveyor belt 9 forms. The holding roller 8 is located above the end of the feeding conveyor belt 9, the right side of the feeding conveyor belt 9 is the opening sawtooth roller 6, the top cover 7 is above the opening sawtooth roller 6, and the product is below the opening sawtooth roller 6. Fiber conveyor belt 5, the left side of the product fiber conveyor belt 5 is a partition plate 4, the left side of the partition plate 4 is a return conveyor belt 3, the left side of the return material conveyor belt 3 is a lifting conveyor belt 1, and the return conveyor belt 3 and above the junction of the lifting conveyor belt 1 is to push up the roller 2.

[0009] The flat waste clothing is sent into the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com