Application of microcrystalline wax in predispersed masterbatch formulation, predispersed masterbatch formulation and preparation method of the formulation

A pre-dispersed masterbatch and rubber technology, which is applied to the application of microcrystalline wax in the pre-dispersed masterbatch formula, the pre-dispersed masterbatch formula and the preparation of the formula, which can solve the impact of safety, health and environmental protection, Poor compatibility between chemicals and rubber, difficulty in uniform dispersion, etc., to achieve the effect of promoting environmental protection of applications, good product performance, and maintaining production and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example is an evaluation of a predispersed masterbatch formulation containing 80% rubber accelerator CBS.

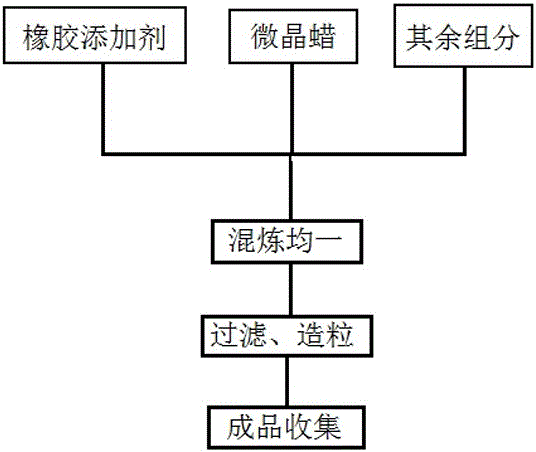

[0039] Such as figure 1 As shown, the pre-dispersed masterbatch particles were weighed according to the combination in Table 1, and the formula processability and rubber Mooney properties were evaluated.

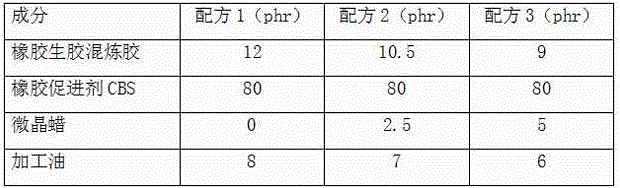

[0040] Table 1 is the pre-dispersed masterbatch formulation with a rubber accelerator CBS content of 80%:

[0041]

[0042] In this test, the application of microcrystalline wax as a low-cost pre-dispersed masterbatch formulation was compared and evaluated. Under the same mixing conditions, the processing performance and Mooney viscosity characteristics of different pre-dispersed masterbatch formulations were compared.

[0043] Table 2 shows the test results of the pre-dispersed masterbatch formulation with a rubber accelerator CBS content of 80%:

[0044]

[0045] As shown in Table 2, the results show that using microcrystalline wax as a test formu...

Embodiment 2

[0047] This example is an evaluation of a predispersed masterbatch formulation containing 80% rubber accelerator TBBS.

[0048] Such as figure 1 As shown, weigh and prepare the pre-dispersed masterbatch mixture according to the combination in Table 3, and evaluate the formulation processability and rubber Mooney properties.

[0049] Table 3 is the predispersed master batch formula containing 80% rubber accelerator TBBS:

[0050]

[0051] In this test, the application of microcrystalline wax as a low-cost pre-dispersed masterbatch formulation was compared and evaluated. Under the same mixing conditions, the processing performance and Mooney viscosity characteristics of different pre-dispersed masterbatch formulations were compared.

[0052] Table 4 is TBBS content 80% predispersed masterbatch formula test result:

[0053]

[0054] As shown in Table 4, the results show that using microcrystalline wax as the test formula to replace the raw rubber compound reduces the amou...

Embodiment 3

[0056] This example is an evaluation of a predispersed masterbatch formulation containing 80% rubber accelerator TMTM.

[0057] Such as figure 1 As shown, weigh and prepare the pre-dispersed masterbatch mixture according to the combination in Table 5, and evaluate the formulation processability and rubber Mooney properties.

[0058] Table 5 is the predispersed masterbatch formula containing 80% rubber accelerator TMTM:

[0059]

[0060] In this test, the application of microcrystalline wax as a low-cost pre-dispersed masterbatch formulation was compared and evaluated. Under the same mixing conditions, the processing performance and Mooney viscosity characteristics of different pre-dispersed masterbatch formulations were compared.

[0061] Table 6 shows the test results of the pre-dispersed masterbatch formulation with 80% TMTM content:

[0062]

[0063] As shown in Table 6, the results show that using microcrystalline wax as the test formula to replace the raw rubber c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com