A construction method for the treatment of concrete porous brick wall without painting and batching putty

A construction method and technology of perforated bricks, applied in covering/lining, architecture, building structure, etc., can solve the problems of not complying with energy saving and consumption reduction, green environmental protection, affecting the quality and durability of wall appearance, and difficult to guarantee project quality. , to achieve the effect of good visual quality, improved environmental protection benefits and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

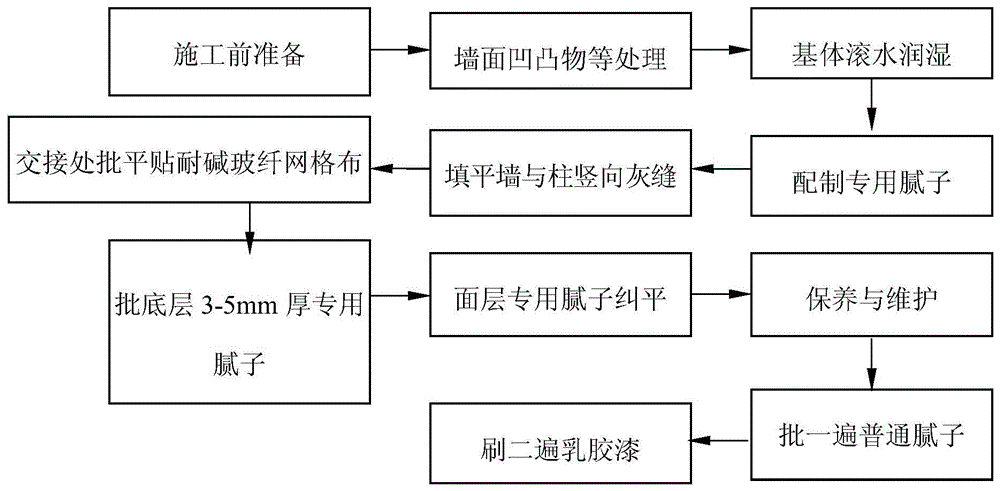

[0021] The newly-built scientific research and design business building invested by Nanjing Architectural Design and Research Institute Co., Ltd. is located in the high-tech industrial park of Baixia District, Nanjing, with an above-ground construction area of 22,200m 2 , The underground construction area is 12800m 2 , The total construction area is 35000m 2 . The method of the present invention was implemented on this building, and the specific method is as follows (such as figure 1 ):

[0022] (1) Preparation for construction: first use a wire support board and a ruler to predict the verticality and flatness of the wall surface, install the putty-based mixed gelling coating thickness on the two sides with different yin and yang angles, and ensure that the wall is vertical, Flat, square yin and yang angles, straight yang angles.

[0023] (2) Clean up the floating ash and mortar on the surface of the masonry, remove the protrusions on the column and beam surface, water and moist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com