Oil recovery method restraining channeling in CO2 flooding process in low-permeability fractured reservoir through two-stage channeling blocking

A low-permeability and fracture technology, applied in chemical instruments and methods, production fluids, earth drilling and production, etc., can solve problems such as water injection difficulties, plugging adjustment technology is difficult to apply, gas injection expansion and volume loss, etc., to improve oil recovery rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

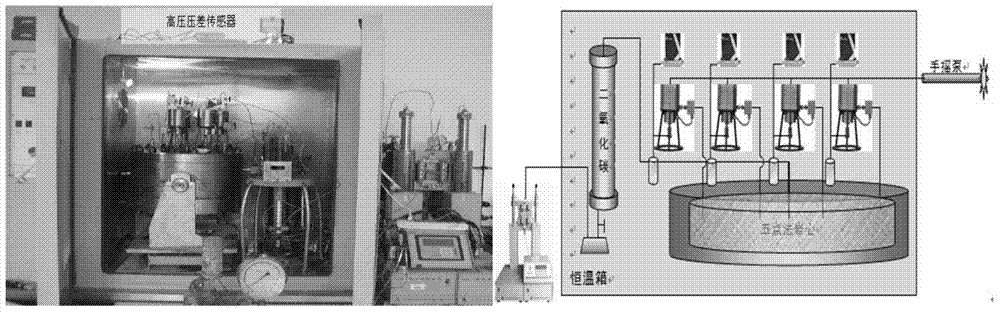

[0049] Experimental conditions

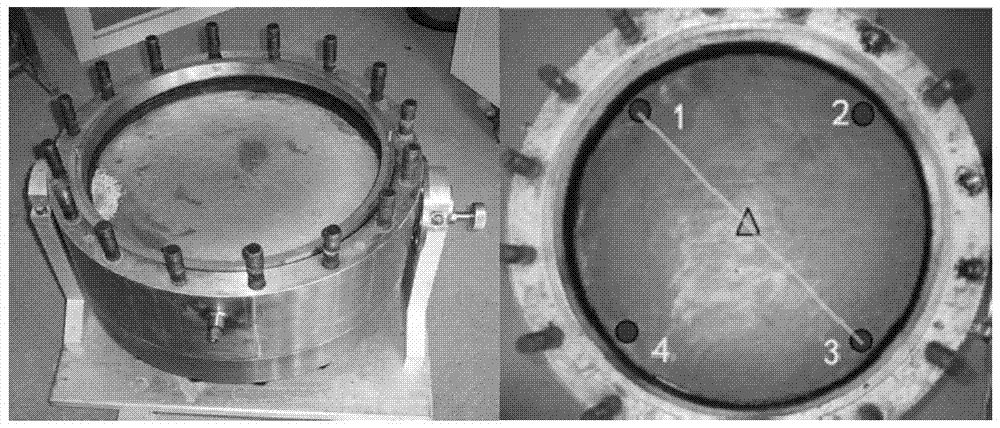

[0050] The size of the physical model is φ400mm×60mm, which is made by drilling, cutting and grinding the natural outcrop. According to the five-point well pattern, one injection and four production well groups are designed.

[0051] Due to the inconsistency in the degree of tightness of the natural outcrop, the permeability from the injection well to the four production wells is also inconsistency, which happens to simulate the site conditions more realistically.

[0052] The physical properties of physical model 1 and the permeability in four directions are shown in Table 1.

[0053] Table 1. Permeability measurement results of the model in Example 1 in each production well direction

[0054]

flow(ml / min)

Differential pressure (KPa)

Matrix permeability (mD)

1 #

0.1

888.39

0.218

2 #

0.4

138.61

5.62

3 #

0.4

122.51

6.39

4 #

0.5

51.81

18.74

...

Embodiment 2

[0080] The physical properties of physical model 2 and the permeability in four directions are shown in Table 3.

[0081] Table 3 Permeability measurement results of the model in Example 2 in each production well direction

[0082]

flow(ml / min)

Differential pressure (KPa)

Matrix permeability (mD)

1 #

0.1

997.63

0.194

2 #

0.4

111.01

7.03

3 #

0.4

168.92

4.63

4 #

0.4

238.01

3.27

[0083] Likewise, at 1 # with 3 # Between the wells, fractures are artificially fractured. The fracture is filled with a small amount of quartz sand with a particle size of about 0.3mm as a fracture proppant, and the measured fracture permeability is 11876.5mD.

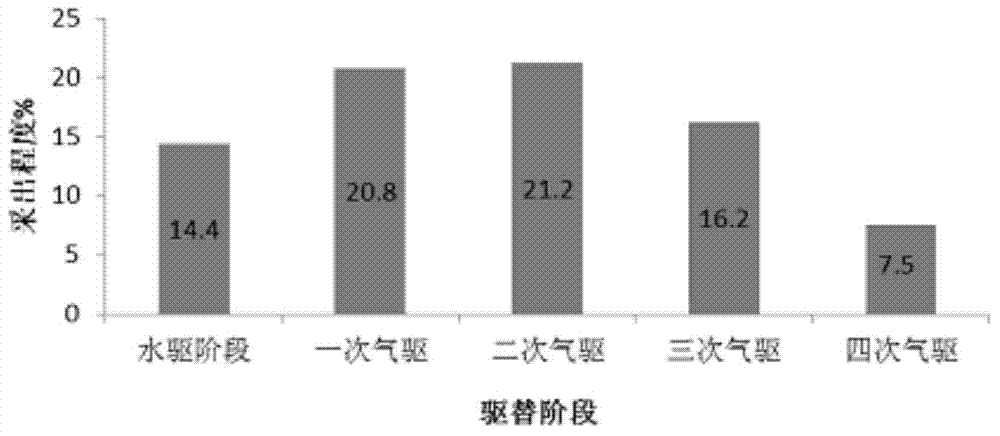

[0084] The same two-stage sealing is carried out, and after the crack sealing, the CO 2 After flooding, the channeling of the relatively high-permeability layer in the matrix was blocked by circulation after gas channeling occurred in a ...

Embodiment 3

[0090] The physical properties of physical model 3 and the permeability in four directions are shown in Table 5.

[0091] Table 5 Permeability measurement results of the model in Example 3 in each production well direction

[0092]

flow(ml / min)

Differential pressure (KPa)

Matrix permeability (mD)

1 #

0.4

296.27

2.62

2 #

0.4

350.5

2.23

3 #

0.4

673.82

1.16

4 #

0.4

609.22

1.28

[0093] In order to further investigate the ability of the two-stage channel sealing to control the heterogeneity of the plane, artificial fractures were constructed from the central well to the # well and 2 # The well forms a "V"-shaped fracture, and a small amount of quartz sand with a particle size of about 0.3mm is also filled in the fracture as a fracture proppant. The measured fracture permeability is 12676.8mD.

[0094] Then start the same operation procedure, the model is driven by gas after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com